You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Closed-system pressurized fermentation technique!

- Thread starter WortMonger

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

haeffnkr

Well-Known Member

Have you tried a pressure washer? Lye?

If none of those work, bail on that keg and get a new one. Once you have a good clean keg, clean it immediately after each use and it will be very easy to clean.

I use a 2' TC cap drilled and tapped to accept a compression coupler for the racking cane and a NPT to accept a T which has a Gas-in post and an adjustable PRV.

Works great, and I would not change a thing.

Need some help please -

I took your advice and bailed on the problem keg and found a different one.

Now the fun really starts-

I have 3 sanke fermenter kegs in rotation. I have been lately putting about 8 gallons of boiling water with about 8 oz of pbw in the water, putting this in the keg, sealed up with a TC and butt cap and let it sit, roll around, flip it every morning and night until I need to get it ready for the next brew... maybe a week or 2 the solution will be in the keg.

I then rinse out the keg with water and then put in a 1/2 gallon of starsan and roll that around in the keg, then fill with wort.....

Before I fill them I use a lighted inspection mirror and saw no gunk/krausen/etc.

I have spray bottles of starsan and always spray spray spray whatever is needed.

I have also switched over to all TC fermenter kits trying to avoid cleaning/infection issues. Re did all the hoses and connections.

The first keg I have tried this with has the same, all be it slight, sour infection, the beer wont clear, has a the smell of the same infection I keep passing around. This is in a Munich Helles, so the infection is not hard to spot.

I used brand new yeast, re did all the liquid hose connection and cleaned them well. Re did the gas hoses also.

Now so far... I have beer in the other 2 kegs that will be racked into cornys this week but so far the samples do not have the infection that I can taste... but of course the infection is easier to tasted as the beer clears up.

I saved the yeast off this batch and tasted the beer that settle out of it, it too taste like the corny keg beer, so there fore the infection started in the keg, or earlier in the process... but I have never had this issue when using carboys... - and actually have some Kolsch in a carboy I will taste soon... to be sure this problem is only related to sanke keg(s)

So do I swap out this keg also? If the keg is clean can it be holding an infection?

What else can I do to clean the kegs better?

How can anything survive boiling PBW that is actually vacuum sealed?

Can an infection be spread by the PRV?

Any help would be appreciated

thanks Kevin

FWIW, I added thermo wells and wish I hadn't. Taping the sensor to the outside with a bit of insulation is way less cyclic.

Yep, and using the stuff that comes with the keg is easier and cheaper too. I did this technique for an easier process for me, not any scientific brewing things or for a coolness factor in brewing over others. I will stick to my simple everything else and focus on making the spunding setup the focus of money spending and gadgetry. These cool attachments are just that, cool. The basic keg hardware and simplicity works!

Need some help please -

Can an infection be spread by the PRV?

Any help would be appreciated

thanks Kevin

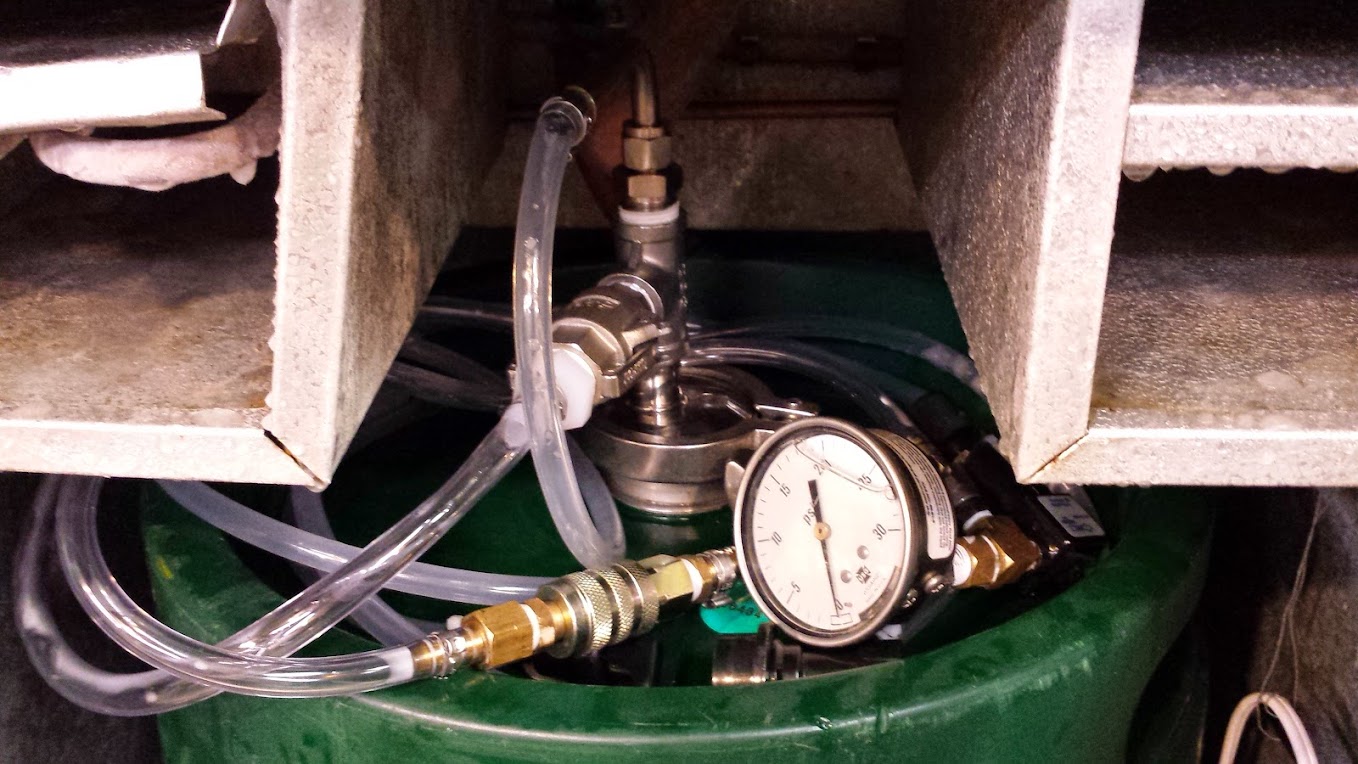

Your cleaning regiment sounds good so I am puzzled. The quick answer to this question is: if, you can't clean out the PRV well and humidity from fermentation is able to possibly go back into the fermentor... then yes. This was a concern of mine early on and so I use a water filter housing for my spunding setup. Then, all I have is tubing leaving the fermentor to worry about cleaning and it is impossible for anything to get back into the fermentor. Beer out-gassing is incredibly sticky so I have tried to minimize that in my spunding valve or PRV as much as is possible, yet it still gets sticky. That is all I can think of to help you out. Some use a whole other keg as I do the water filter housing.

haeffnkr

Well-Known Member

Your cleaning regiment sounds good so I am puzzled. The quick answer to this question is: if, you can't clean out the PRV well and humidity from fermentation is able to possibly go back into the fermentor... then yes. This was a concern of mine early on and so I use a water filter housing for my spunding setup. Then, all I have is tubing leaving the fermentor to worry about cleaning and it is impossible for anything to get back into the fermentor. Beer out-gassing is incredibly sticky so I have tried to minimize that in my spunding valve or PRV as much as is possible, yet it still gets sticky. That is all I can think of to help you out. Some use a whole other keg as I do the water filter housing.

Interesting point -

How do you clean the valve?

Do you still use a water barrier to separate the spunding valve from the keg?

I see a lot of folks who have the valve screwed right onto the TC hardware that seems like you would have to clean that all every time.

so I have all my parts on order and they should arrive today. one question though what gauge psi should I get 0-30, 0-60 0-100 and should this be liquid filled or dry? I'd think dry would be fine. I am getting the gauge for free from a vendor for the price of a 12oz homebrewed beer.

-=Jason=-

-=Jason=-

I take mine apart and clean it. I haven't bought the one like you have yet. I recommended it because it works better to release pressure, but I didn't know you couldn't take it apart. I need to buy another one because both of mine have corroded where the steel meets the brass. I may make one in machine shop out of stainless and be done with it.Interesting point -

How do you clean the valve?

Do you still use a water barrier to separate the spunding valve from the keg?

I see a lot of folks who have the valve screwed right onto the TC hardware that seems like you would have to clean that all every time.

The water barrier helped keep everything but the sticky gas out of the valve, but didn't 100% fix the problem of the valve getting sticky.

I started out with the valve right on the TC, I had to clean it every time.

so I have all my parts on order and they should arrive today. one question though what gauge psi should I get 0-30, 0-60 0-100 and should this be liquid filled or dry? I'd think dry would be fine. I am getting the gauge for free from a vendor for the price of a 12oz homebrewed beer.

-=Jason=-

I would do 0-60 since it hits every pressure you would need. I would also tell you to use liquid filled, as they can't let in any of the corrosion into the innards of the gauge since glycerine is there already. I believe the one I bought was for corrosive use IIRC so I didn't have to worry about that either.

haeffnkr

Well-Known Member

I take mine apart and clean it. I haven't bought the one like you have yet. I recommended it because it works better to release pressure, but I didn't know you couldn't take it apart. I need to buy another one because both of mine have corroded where the steel meets the brass. I may make one in machine shop out of stainless and be done with it.

The water barrier helped keep everything but the sticky gas out of the valve, but didn't 100% fix the problem of the valve getting sticky.

I started out with the valve right on the TC, I had to clean it every time.

Hmmm.... so you you put the water filter on it to isolate any contamination from the previously used spunding valve or to keep it from getting sticky or both?

I remember now that on this keg/batch I started with just a plug and bubbler and the fermentation was going on about 4 days before I put on my TC hardware/spunding valve.

It went up to 5 pounds in a few hours soon as I put on the spunding valve.

So either the keg had the infection in it some how or the infection was in the spunding valve that could travel back down the tube against pressure to infect the batch?

Is that even possible?

Trying to understand how the infection could go backwards down tubing against pressure.

thanks Kevin

At some point the pressure release stopped right? At that point liquid could come back out of the valve.

haeffnkr

Well-Known Member

At some point the pressure release stopped right? At that point liquid could come back out of the valve.

Not trying to argue ... trying to understand so stay with me please.

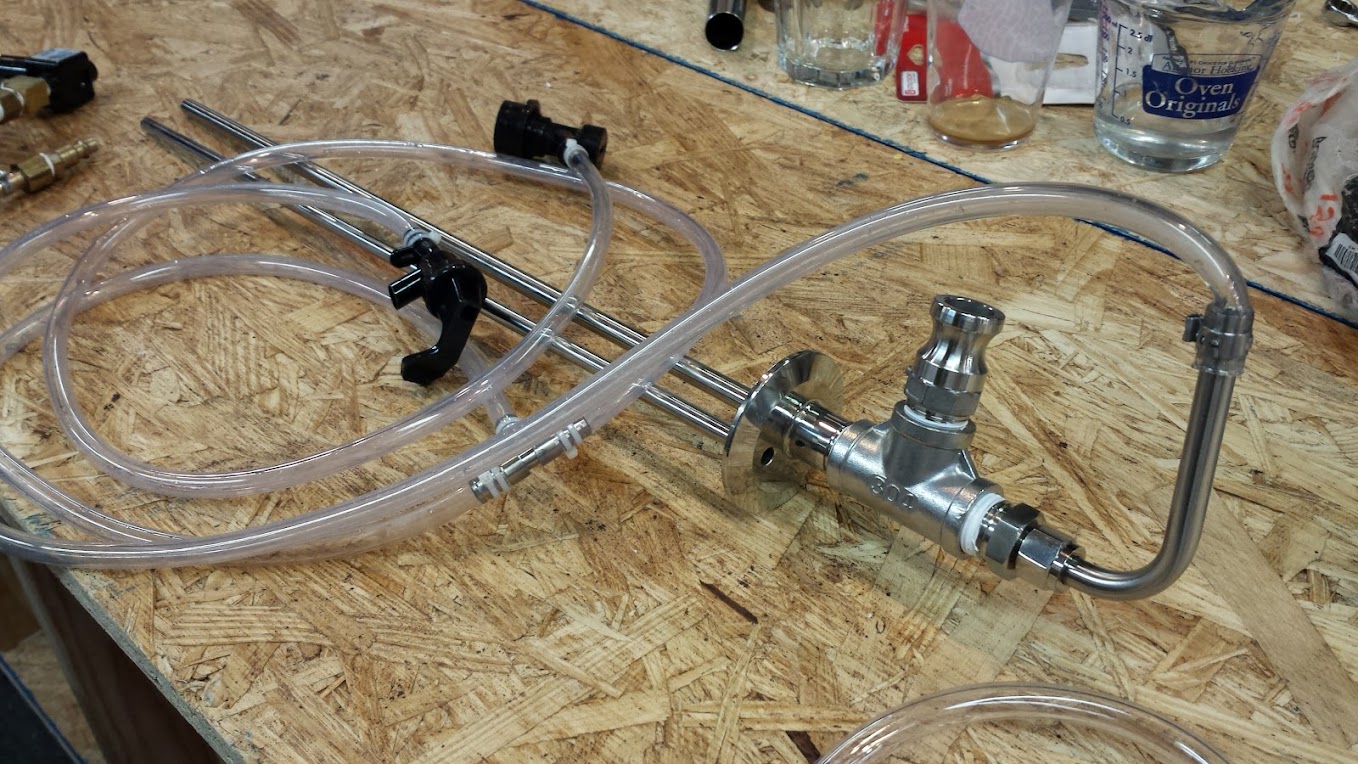

Here is my new setup -

I dont see how any liquid could go back through all this hose and fittings, gas maybe? You said liquid though, just trying to make sure we are on the same page.

I see a lot of guys who have spunding valve right on the Tee or Cross but I put the cam lock on there so I can take off the gas side and clean the liquid side.

thoughts?

thanks Kevin

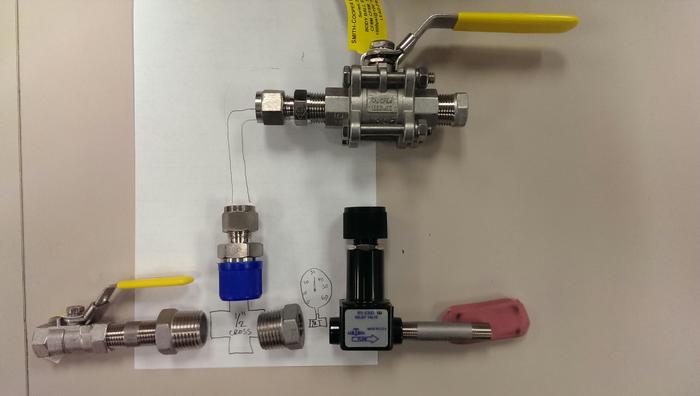

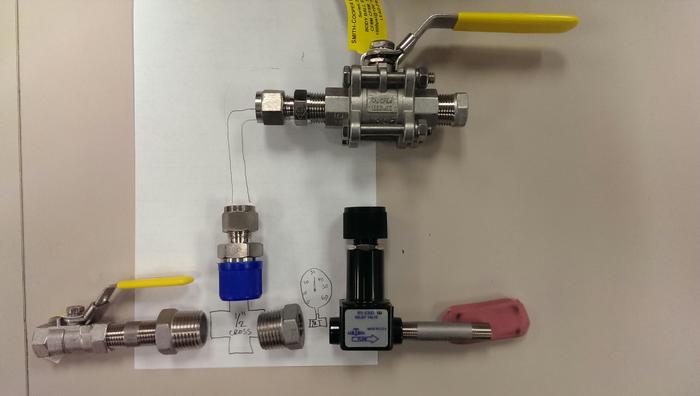

So here is what I have so far. it will be going on the www.BrewHardware.com Tri-Clover setup.

I'll have a 1/4" SS Flare fitting on the gas valve and the liquid out valve. that way I can connect using existing tubing. I have a set of 1/2" camlocks I was thinking about possibly putting between the cross and prv / gauge assembly. not sure why but I've seen a few other setups with the gas side able to be disconnected. is that so you can run without the PRV and Gauge for a day or so and then put it on and start building pressure.

-=Jason=-

I'll have a 1/4" SS Flare fitting on the gas valve and the liquid out valve. that way I can connect using existing tubing. I have a set of 1/2" camlocks I was thinking about possibly putting between the cross and prv / gauge assembly. not sure why but I've seen a few other setups with the gas side able to be disconnected. is that so you can run without the PRV and Gauge for a day or so and then put it on and start building pressure.

-=Jason=-

Based on a comment from WortMonger, for my first batch, I went straight to PRV after pitching and fermented to 10 psi for the majority prior to ramping up for carbonation. I've read from others that they ferment at a lower psi ~3-5. Not sure of any attenuation differences of the selected value but my first batch went fabulous!

Kevin, I can't see that your setup would do what I mentioned unless you picked up your spunding setup allowing anything to go back in the fermentor. I just find it hard to believe that that many kegs would taint the brews you have done. This makes me think either: 1) something is happening during your fermentation (ie pressure ramp too high too fast making the yeast through off flavors, which I don't see from your procedures posted) or 2) you are tainted prior to entering the fermentor either with transfer tubing, chiller, or airborne during your chill. I really don't know! You may have to wait until you try your carboy beer to really tell.Not trying to argue ... trying to understand so stay with me please.

Here is my new setup -

I dont see how any liquid could go back through all this hose and fittings, gas maybe? You said liquid though, just trying to make sure we are on the same page.

thoughts?

thanks Kevin

So it's been a while since I read the first page. I'll reread it but are most people going straight from pitching yeast to using the prv? Or using a blow off tube and then putting the prv on?

I use the PRV from the get go. I don't want any chance of airborne anywhere in my process other than when I am transferring. The whole purpose for me with 15 gallons in a 15.5 gallon keg is to keep that krausen down with the 5-10 psi as soon as possible. Of course, that is why I went with the filter housing to catch the stuff that makes it through. Just like top croppers, I get liquid in the housing from the blow off. I wish I didn't! With your setup, you will get it too, and if that PRV isn't easily cleanable like others have brought up then I wouldn't do more beer than would make the blow off happen. I can't tell you how much, because I have always just let it happen with 15 gallons. I really need to try Fermcap-S to see if that absolutely fixes the problems I have had. Heck, that stuff says it increases bitterness by 10% due to no blow-off. Who wouldn't want to decrease their bittering hops by 10% and prevent the mess. If I could turn my housing into a bubbler, not a foamy blow-off container, I wouldn't have so much worry about cleaning my PVR.

Your technique is just that, your technique! It works no matter how you do it, just understand what you are trying to accomplish and do what you have to do to accomplish it. Hope you don't have the infection problems Kevin has had.

To everyone doing this: remember that there is a buffer at the beginning. If the first day your pressure gets too high, it is only head pressure! Dial down and you should have no problems (other than a potential foamy mess problem that is). If it is a couple of days into ferment and it gets way too high, then you might have problems with the yeast because the beer is saturated and you have head pressure. I think about it like bottle conditioning. I want 5-10 psi until I am ready to carbonate, then I crank it up. Too early, potential yeast problems. Too late, I have to carbonate with my gas bottle. I haven't had to do this yet, but I have had pressure go up to scary levels in the beginning. I would rather walk out the day after pitching and smell the burn at 1-2 psi and have to dial up to 5-10 psi, than to walk out smell the burn and have to start dialing down and clean up foam all over the place. Yep, been there many times. Even had a mess going from 15 psi to 10 psi before. I take it to the limit though with .5 gallon space to spare. Have to remember to try Fermcap-S.:rockin:

Based on a comment from WortMonger, for my first batch, I went straight to PRV after pitching and fermented to 10 psi for the majority prior to ramping up for carbonation. I've read from others that they ferment at a lower psi ~3-5. Not sure of any attenuation differences of the selected value but my first batch went fabulous!

Great! How much are you fermenting and in what size container? Curious if you had any krausen foam problems? Also, what hardware are you using (regular tap connector or something else)? Any buffer from keg to PRV or are you right on top with it?

Great! How much are you fermenting and in what size container? Curious if you had any krausen foam problems? Also, what hardware are you using (regular tap connector or something else)? Any buffer from keg to PRV or are you right on top with it?

Don't have pictures right now but essentially my setup is a 15.5 Sanke, a TC setup from BrewHardware.com that has a 1/2" male and a thermowell. Then I have a 4 way with one side being a gas Corny post, the other side a PRV and gauge, and the top is a racking cane. The racking cane has a ball valve and liquid corny post. Outside of a nipple, there is nothing prohibiting the krausen from hitting the PRV.

I do 11 gallon batches and didn't have any krausen issues on this batch. First one though!

haeffnkr

Well-Known Member

Kevin, I can't see that your setup would do what I mentioned unless you picked up your spunding setup allowing anything to go back in the fermentor. I just find it hard to believe that that many kegs would taint the brews you have done. This makes me think either: 1) something is happening during your fermentation (ie pressure ramp too high too fast making the yeast through off flavors, which I don't see from your procedures posted) or 2) you are tainted prior to entering the fermentor either with transfer tubing, chiller, or airborne during your chill. I really don't know! You may have to wait until you try your carboy beer to really tell.

I appreciate you staying with me here -

I am still banging my head on the wall.

My last batch was 12 gallons of Kolsch split into 2 6.5 carboys, made on 7/7.

One was put in my ferment frige and one was put into a swamp cooler.

I racked off both carboys last night, both tasted great, no sour wangs that I keep tasting in my keg fermented batches. There was a slight difference between the 2 since the swamp cooler got a bit hotter than the frige fermented one, so there was a tiny bit more Kolsch ester in the one that got hotter, But again, I expect no issues... more to come after it ages a week and carbs up.

Oh Yeah....I screwed up the recipe for this Kolsch and made it for 14 gallons but it was actually 12 and thus I made a gallon of 55 IBU hop juice on 7/10 to bump up the IBU and drop the SG, but even after pouring more stuff back into both fermenters, it taste good.

I also made 12 gallons of Octoberfest on 7/7 and started with a bubbler, I tasted that batch last night and I am not sure if the malt is not hiding the sour wang ....I think it might be more to come.

But... the BUD clone I made on 7/3 has the wang and slight acid/vinegar smell worse than the slight wang I have in my Munich Helles from 6/28.

I know it seems crazy to think I have 4 kegs now that I can not get clean.

The BUD keg was a new to me keg, that was soaked in my same regime of 8 gallons of boiling PBW, 8 oz pbw in the mix and stayed in there for about a week.

I kept flipping and rolling the keg 2-3 times a day.

I keep emailing/PM others about their setups... I am at a loss why I can not get them clean.

I am now going to throw more money at the problem and will put on some 8" TC fitting on my kegs to get my arm in there and clean them.

I will also be making my light lagers again in Carboys to try and narrow things down, I had none of these problems in the 20 plus batches made the same way I do today, when I used Carboys.

Also on the Munich Helles batch I had the yeast starter made a few weeks in advance, I drank a class of the starter beer after it was in the frige for 2 weeks, it was great and taste nothing like what I have now.

Also I have an immersion chiller that I put in the boiling wort 20 minutes before the boil is up. I have a short 2 foot hose that dumps from BK to fermenter that is cleaned with Starsan and water every time I touch it.

All that said, I am thinking this is all fermenter related.

Keep the ideas coming!

thanks Kevin

1MadScientist

Well-Known Member

thefrost posted recently here; https://www.homebrewtalk.com/f13/cl...ion-technique-44344/index200.html#post6240935

'How to clean this thing' - McMaster Carr "Adjustable Pressure-Maintaining

Compact Plastic Relief Valves, #99045K11"

Has anybody figured out how to take it apart for inspection/cleaning?

2/17/2013 by Mad Scientist Brewhaus, on Flickr

2/17/2013 by Mad Scientist Brewhaus, on Flickr

'How to clean this thing' - McMaster Carr "Adjustable Pressure-Maintaining

Compact Plastic Relief Valves, #99045K11"

Has anybody figured out how to take it apart for inspection/cleaning?

2/17/2013 by Mad Scientist Brewhaus, on Flickr

2/17/2013 by Mad Scientist Brewhaus, on Flickrchapusin

Well-Known Member

Based on a comment from WortMonger, for my first batch, I went straight to PRV after pitching and fermented to 10 psi for the majority prior to ramping up for carbonation. I've read from others that they ferment at a lower psi ~3-5. Not sure of any attenuation differences of the selected value but my first batch went fabulous!

This is what I do, dump wort into fermenter at around 80-90 (hard to get it lower in san diego without a prechiller), the fermenter sits inside the stand up fridge so when it gets to around 75 I pitch the yeast, turn the prv to around where I know it will get to 10 psi and let it ferment. Now, on my last batch I took my stout to 20 psi on the last few points of gravity so it could naturally carb but then when I had to drop in some vanilla beans, so I started letting the gas vent, I must have done it too quickly because when I opened the lid, foam came out like crazy!

How do you guys do this when you have to put hops in or any other stuff?

haeffnkr

Well-Known Member

haeffnkr - Do you force carb after kegging, or do you naturally carb by cranking up the spunding and transfer to serving under counter-pressure?

I try to carb up some naturally and transfer under CO2.

I still have to force carb some to get it to serving pressure.

haeffnkr - how about trying to brew a cheap batch with a drilled stopper and air lock in lieu of the spunding valve. I'm guessing it's the source of your infection.

Good idea

I will even try to split a batch into a carboy and a keg, both with stoppers/air locks and push both out with CO2 to serving corny kegs.

thanks Kevin

This is what I do, dump wort into fermenter at around 80-90 (hard to get it lower in san diego without a prechiller), the fermenter sits inside the stand up fridge so when it gets to around 75 I pitch the yeast, turn the prv to around where I know it will get to 10 psi and let it ferment. Now, on my last batch I took my stout to 20 psi on the last few points of gravity so it could naturally carb but then when I had to drop in some vanilla beans, so I started letting the gas vent, I must have done it too quickly because when I opened the lid, foam came out like crazy!

How do you guys do this when you have to put hops in or any other stuff?

I counter pressure transfer into a second keg with the dry hops already in it so I don't lose any pressure.

I also live in San Diego. Switching to a plate chiller helped to get temps below the 80s. In the winter my tap water is 65 so I can bring it right down to where it should be. This time of year I can only get it to 70-75.

How do you guys do this when you have to put hops in or any other stuff?

Pickles mentioned doing secondary additions in the serving keg. I just did this with some hops and it was great. Put the additions in prior to pressurizing so you don't expose to oxygen.

Sent from my iPhone using Home Brew

+1 to this ^^^^

The other benefit is that you can put the hops or whatever in the second vessel and purge with CO2 them you the spunding valve to transfer foam free.

Edit: Jimyson beat me to the punch

The other benefit is that you can put the hops or whatever in the second vessel and purge with CO2 them you the spunding valve to transfer foam free.

Edit: Jimyson beat me to the punch

chapusin

Well-Known Member

Pickles mentioned doing secondary additions in the serving keg. I just did this with some hops and it was great. Put the additions in prior to pressurizing so you don't expose to oxygen.

Sent from my iPhone using Home Brew

Yep, that's what I had to do, I put all the vanilla beans in the keg, pressurized it and then started to transfer from the conical to the keg. Drop the temp to 40 and finish carbonating.

Hmm, maybe I'm not following, but why did you open the keg after transferring onto vanilla beans? Did you use the spunding valve to counter pressure fill the keg from the conical? If you did it sounds like you just need to slow things down a bit.

Here's my procedure if anyone cares. When I'm done fermenting and ready to transfer, whether it be to a serving keg or secondary (not secondary in the typical homebrew sense); I pressurize both conical and keg to the same pressure (close to end of ferment pressure but arbitrary). I put spunding valve on the fermenter with CO2 on and adjust until "hissing" stops; then put spunding valve on the "gas in" of (already pressurized) keg and adjust until "hissing" starts. With spunding valve on keg, I put gas back on the fermenter, then place jumper between "fermenter out" and "keg in". The flow will start immediately following connection of the entire system. Transfer takes about 20 minute for 4.5 gallons. I'll typically fill three 5 gallon cornies from one batch. I don't get too concerned about exact pressure settings so long as the receiving vessel has slightly lower pressure than the source (fermenter); I can always top off CO2 to serving pressure in the keezer. Since I have a tri-clamp brewhemoth conical and cornie kegs I decided to use 1/4" MFL fittings as the common denominator. I brazed some 1.5" tri-clamp fittings to 1/4" MFL fittings to attach hoses to 1/4" MFL cornie connectors, the spunding valve, a picnic tap, etc. This allows me to have a few different lengths of hoses that can be used for tons of applications.

My $0.10...

My $0.10...

Here's my procedure if anyone cares. When I'm done fermenting and ready to transfer, whether it be to a serving keg or secondary (not secondary in the typical homebrew sense); I pressurize both conical and keg to the same pressure (close to end of ferment pressure but arbitrary). I put spunding valve on the fermenter with CO2 on and adjust until "hissing" stops; then put spunding valve on the "gas in" of (already pressurized) keg and adjust until "hissing" starts. With spunding valve on keg, I put gas back on the fermenter, then place jumper between "fermenter out" and "keg in". The flow will start immediately following connection of the entire system. Transfer takes about 20 minute for 4.5 gallons. I'll typically fill three 5 gallon cornies from one batch. I don't get too concerned about exact pressure settings so long as the receiving vessel has slightly lower pressure than the source (fermenter); I can always top off CO2 to serving pressure in the keezer. Since I have a tri-clamp brewhemoth conical and cornie kegs I decided to use 1/4" MFL fittings as the common denominator. I brazed some 1.5" tri-clamp fittings to 1/4" MFL fittings to attach hoses to 1/4" MFL cornie connectors, the spunding valve, a picnic tap, etc. This allows me to have a few different lengths of hoses that can be used for tons of applications.

My $0.10...

My $0.10...

chapusin

Well-Known Member

Hmm, maybe I'm not following, but why did you open the keg after transferring onto vanilla beans? Did you use the spunding valve to counter pressure fill the keg from the conical? If you did it sounds like you just need to slow things down a bit.

Maybe I didn't explain myself. I wanted to add the beans to the conical but the lid almost exploded with foam when I depressurized, so I closed the lid again and put the vanilla beans in the secondary instead (my sanke keg is my secondary). Transfered from the conical to the secondary and next week I'll transfer to another keg for serving/bottling.

I've read that this technique will suppress ester production this allowing fermentation at higher temps. Anyone have experience fermenting in the higher temperature range?

Yesterday afternoon I pitched a starter into 60F wort, set spunding valve to 7psi and closed up the ferm chamber set at 63F. I then left town to go to a wedding. When I returned 24 hrs later I found the GFCI tripped and temp was at 73F and 7psi. I'm assuming in that time that not a whole lot of off flavors were generated but it got me curious about how high people have pushed things.

Yesterday afternoon I pitched a starter into 60F wort, set spunding valve to 7psi and closed up the ferm chamber set at 63F. I then left town to go to a wedding. When I returned 24 hrs later I found the GFCI tripped and temp was at 73F and 7psi. I'm assuming in that time that not a whole lot of off flavors were generated but it got me curious about how high people have pushed things.

You should be fine pickles! I've done a test batch at room temperature once and it was fine other than my pressure got too high and made a mess during that correction. What is it? APA hopefully or something hoppy will help in case of slight flavor problems just in case. I drank my keg so fast I couldn't tell you if it might have a problem later on down the road.

Sent from my iPhone using Home Brew

Sent from my iPhone using Home Brew

It will come out great then. Did you check gravity when you got back? Might be done and ready for carbonation already.

Sent from my iPhone using Home Brew

Sent from my iPhone using Home Brew

Questions:

Since you are maintaining pressure in your fermenter, how are you all taking gravity readings? Push some out of the siphon tube?

How do you ensure that the carbonation level does not throw off your hydrometer? Just stir the sample vigourously to make it flat?

Since you are maintaining pressure in your fermenter, how are you all taking gravity readings? Push some out of the siphon tube?

How do you ensure that the carbonation level does not throw off your hydrometer? Just stir the sample vigourously to make it flat?

Yes, out of a serving tap usually. Most of us estimate with a refractometer instead of using a hydrometer, so no worry of carbonation. If I use a hydrometer I degas before reading. I usually only use a hydrometer in the kettle and then again when my first beer hits my glass.

Sent from my iPhone using Home Brew

Sent from my iPhone using Home Brew

It will come out great then. Did you check gravity when you got back? Might be done and ready for carbonation already.

Sent from my iPhone using Home Brew

No I didn't but i tasted it and it was still very sweet.

.....

I've read that this technique will suppress ester production this allowing fermentation at higher temps. Anyone have experience fermenting in the higher temperature range?

Yesterday afternoon I pitched a starter into 60F wort, set spunding valve to 7psi and closed up the ferm chamber set at 63F. I then left town to go to a wedding. When I returned 24 hrs later I found the GFCI tripped and temp was at 73F and 7psi. I'm assuming in that time that not a whole lot of off flavors were generated but it got me curious about how high people have pushed things.

I do not have fermentation temperature control and typically get up in the 72-75 range. Beer always tastes great to me and everyone that has had it this far. I was told by someone though that my barleywine had a very slight ester taste so take it for what it's worth. Let me as though that it was an English Style Barleywine so I guess it could be "acceptable". Fermentation control is in my future though.

Sent from my iPhone using Home Brew

Similar threads

- Replies

- 13

- Views

- 595

- Replies

- 34

- Views

- 692

- Replies

- 8

- Views

- 1K