joshrosborne

Well-Known Member

I posted this on my blog and thought it might be of interest to the forum. As I note on the bottom, if any of the info or nomenclature I use is incorrect, please let me know so I can edit it. I'll be following this general post up with an pictorial example (a strawberry Berliner Weisse) that I'll be starting tonight and will post here as well.

As the thirst for sour and funky beer has taken over the craft beer scene in the form of lambics, Berliner Weisses, and various other Brettanomyces and bacteria-inspired beers; homebrewers have also taken a hankering for trying their hand at these unique beers. There is a large gap, however, between the ease of acquiring a bottle of many sour/funky beers and being able to drink a bottle of your own creation. In the former case, you merely have to skip down to your better beer store and part ways with some cash; the latter involves much, much more time and effort. Particularly time: many lambics and sours take upwards of one to two years to 1) reach an acceptable flavor profile and, 2) reach terminal gravity so you don’t have exploding bottles as fermentation continues in them.

With this in mind, it’s no wonder that there hasn’t been an explosion of homebrewing sours. Sure, I’m certain more people are doing so than 1, 5, or 10 years ago, but the number of these people are dwarfed by both the number of new homebrewers and the number of new fans of sours. It makes sense since patience is not a virtue that is widely held by the human race. I bottled my last IPA 8 days after brewing it; I bottled by first sour 13 months after brewing it. Is there no hope for sour beer lovers who would hope to crank something out in a month or two that is both sour and drinkable? This is where sour mashing comes into play.

With most sour beers, a number of critters, both yeast and bacteria, come into play. In Wyeast’s Lambic Blend, for instance, there exists a Belgian style Saccharomyces Cerevisiae (this is the yeast strain of most, if not all brewer’s yeasts), a sherry yeast strain, two Brettanomyces strains, a Lactobacillus culture, and a Pediococcus culture. Both Lactobacillus and Pediococcus are souring bacterias; in a lambic, most of the sourness will come from the Pedio, which takes much longer to create sourness than Lacto. It also provides a much more complex flavor than Lacto. Taste a lambic and then taste a Berliner Weisse and you will understand the different I refer to. Acetobacter is also a souring bacteria, but the souring flavor it provides is vinegar-like and is not desirable in most style of beer except Oud Bruins and Flanders Reds. Also, I would like to note that in most cases, despite what many people believe, Brettanomyces yeast will not provide sourness except in rare instances. Tart yes, sour no.

Sour mashing basically involves one of these critters and that is Lactobacillus delbrueckii. Other strains of Lacto (acidophilus) are found in yogurts and is responsible for its signature tangy-ness. It thrives in high temperatures, which is why we will be sour mashing our wort at somewhere between 104-111 Fahrenheit. Not only is this the temperature at which the Lacto is going to make your beer sour the quickest, but it is also at a high enough level that most other undesirable spoiling bacteria will not reproduce effectively. Lacto will reproduce (and sour your beer) anaerobically, which is great because the exposure to air will invite Acetobacter, the undesirable bacteria noted above.

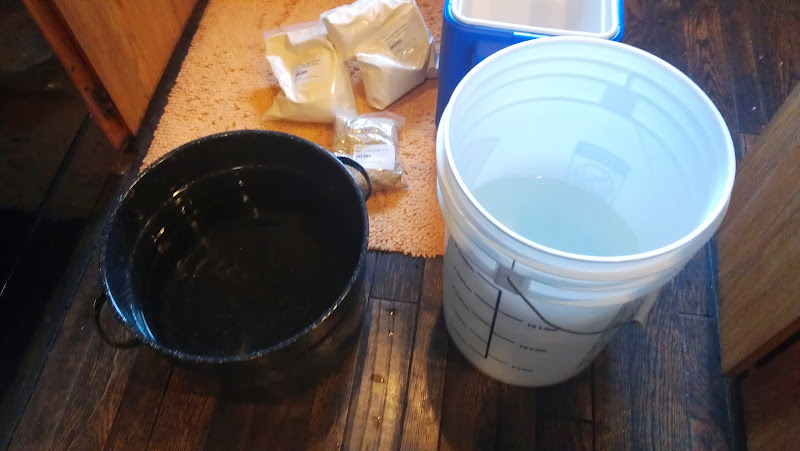

Sour mashing in beer is not a new process, but it’s not one that has been nailed down to a science. The general process is this: get a fermentable-rich wort ready, through all-grain methods or by dissolving malt extract in water; cool the wort down to 110-115; introduce the Lacto, either by throwing in a handful of grain which is covered by it, or by using a commercial culture; eliminate or at least reduce air exposure by flushing vessel with CO2 or by laying plastic wrap over the wort’s surface; hold temperatures at where you have it; and wait. Monitoring every day or so is a good idea to make sure you can pick when it’s as sour as you like. I find that 2-3 days is about ideal.

Once it’s to your likings in terms of sourness, boil with a tiny bit of hops. The boil will kill the Lacto and fix the sourness at the level you chose. After boiling, chill as normal and pitch your preferred yeast strain to ferment out. You don’t need to worry about spoiling your equipment with the bacteria, as the boil has killed all of it already. Bottle, wait for carbonation, and enjoy your quickly brewed sour!

I will be following up this post with an actual example of a strawberry Berliner Weisse that I will be doing over the next month or so. I am actually starting the sour mash tonight. If you have any question about the above, or the process in general, please submit them in the comments and I will answer them to the best of my ability.

(Note: I am not a scientist or even a brewing expert, so if any of the science above is incorrect, please let me know in the comments and I will edit as needed.)

Edit: Accidentally swapped Lacto acidophilus for Lacto delbrueckii above. They are not the same thing, as noted in the posts below.

As the thirst for sour and funky beer has taken over the craft beer scene in the form of lambics, Berliner Weisses, and various other Brettanomyces and bacteria-inspired beers; homebrewers have also taken a hankering for trying their hand at these unique beers. There is a large gap, however, between the ease of acquiring a bottle of many sour/funky beers and being able to drink a bottle of your own creation. In the former case, you merely have to skip down to your better beer store and part ways with some cash; the latter involves much, much more time and effort. Particularly time: many lambics and sours take upwards of one to two years to 1) reach an acceptable flavor profile and, 2) reach terminal gravity so you don’t have exploding bottles as fermentation continues in them.

With this in mind, it’s no wonder that there hasn’t been an explosion of homebrewing sours. Sure, I’m certain more people are doing so than 1, 5, or 10 years ago, but the number of these people are dwarfed by both the number of new homebrewers and the number of new fans of sours. It makes sense since patience is not a virtue that is widely held by the human race. I bottled my last IPA 8 days after brewing it; I bottled by first sour 13 months after brewing it. Is there no hope for sour beer lovers who would hope to crank something out in a month or two that is both sour and drinkable? This is where sour mashing comes into play.

With most sour beers, a number of critters, both yeast and bacteria, come into play. In Wyeast’s Lambic Blend, for instance, there exists a Belgian style Saccharomyces Cerevisiae (this is the yeast strain of most, if not all brewer’s yeasts), a sherry yeast strain, two Brettanomyces strains, a Lactobacillus culture, and a Pediococcus culture. Both Lactobacillus and Pediococcus are souring bacterias; in a lambic, most of the sourness will come from the Pedio, which takes much longer to create sourness than Lacto. It also provides a much more complex flavor than Lacto. Taste a lambic and then taste a Berliner Weisse and you will understand the different I refer to. Acetobacter is also a souring bacteria, but the souring flavor it provides is vinegar-like and is not desirable in most style of beer except Oud Bruins and Flanders Reds. Also, I would like to note that in most cases, despite what many people believe, Brettanomyces yeast will not provide sourness except in rare instances. Tart yes, sour no.

Sour mashing basically involves one of these critters and that is Lactobacillus delbrueckii. Other strains of Lacto (acidophilus) are found in yogurts and is responsible for its signature tangy-ness. It thrives in high temperatures, which is why we will be sour mashing our wort at somewhere between 104-111 Fahrenheit. Not only is this the temperature at which the Lacto is going to make your beer sour the quickest, but it is also at a high enough level that most other undesirable spoiling bacteria will not reproduce effectively. Lacto will reproduce (and sour your beer) anaerobically, which is great because the exposure to air will invite Acetobacter, the undesirable bacteria noted above.

Sour mashing in beer is not a new process, but it’s not one that has been nailed down to a science. The general process is this: get a fermentable-rich wort ready, through all-grain methods or by dissolving malt extract in water; cool the wort down to 110-115; introduce the Lacto, either by throwing in a handful of grain which is covered by it, or by using a commercial culture; eliminate or at least reduce air exposure by flushing vessel with CO2 or by laying plastic wrap over the wort’s surface; hold temperatures at where you have it; and wait. Monitoring every day or so is a good idea to make sure you can pick when it’s as sour as you like. I find that 2-3 days is about ideal.

Once it’s to your likings in terms of sourness, boil with a tiny bit of hops. The boil will kill the Lacto and fix the sourness at the level you chose. After boiling, chill as normal and pitch your preferred yeast strain to ferment out. You don’t need to worry about spoiling your equipment with the bacteria, as the boil has killed all of it already. Bottle, wait for carbonation, and enjoy your quickly brewed sour!

I will be following up this post with an actual example of a strawberry Berliner Weisse that I will be doing over the next month or so. I am actually starting the sour mash tonight. If you have any question about the above, or the process in general, please submit them in the comments and I will answer them to the best of my ability.

(Note: I am not a scientist or even a brewing expert, so if any of the science above is incorrect, please let me know in the comments and I will edit as needed.)

Edit: Accidentally swapped Lacto acidophilus for Lacto delbrueckii above. They are not the same thing, as noted in the posts below.