its02003

Well-Known Member

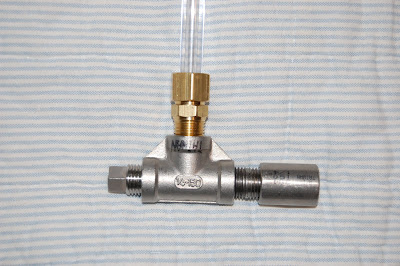

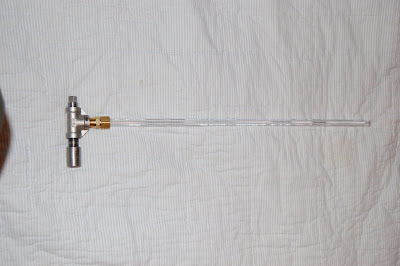

Testing the waters to see if anyone is interested in a sight glass.

I am going to try and build my own for my setup and McMaster gives pretty good bulk discounts on items.

I don't mind putting them together, as long as people are willing to pay for the materials and shipping....the savings with the bulk purchasing will be enough to me.

If you think you might be interested, PM me and I will get a price sheet together.

I am going to try and build my own for my setup and McMaster gives pretty good bulk discounts on items.

I don't mind putting them together, as long as people are willing to pay for the materials and shipping....the savings with the bulk purchasing will be enough to me.

If you think you might be interested, PM me and I will get a price sheet together.