LandoLincoln

Well-Known Member

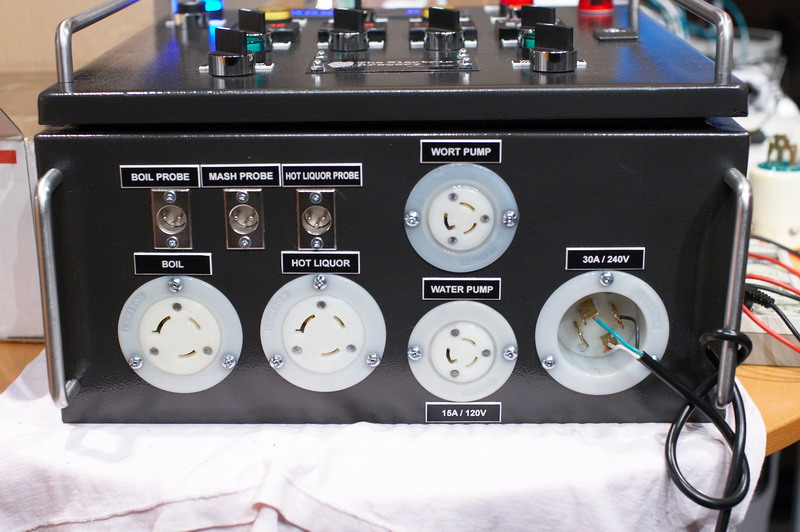

So I finally completed my 240v 50a control panel, but it's going to be a month or two before I get the 240v 50a service set up in my basement, and I'm really curious to see if everything is working okay on my control panel.

I don't need to test the element outlets, I just wanted to make sure that the contactors and switches and PIDs and pump outlets were working as they're supposed to.

The contactor coils are all 120v as well, btw.

So...yeah...I don't think that there would be anything wrong hooking this baby up to a 120v 15a GFCI cord, splitting the hot wire to run into both hot lines of the 240v system and plugging it into the wall. Since I'm not running any elements at this time, there's no need for 240v service.

Right? Or should I just cool my jets and wait?

I don't need to test the element outlets, I just wanted to make sure that the contactors and switches and PIDs and pump outlets were working as they're supposed to.

The contactor coils are all 120v as well, btw.

So...yeah...I don't think that there would be anything wrong hooking this baby up to a 120v 15a GFCI cord, splitting the hot wire to run into both hot lines of the 240v system and plugging it into the wall. Since I'm not running any elements at this time, there's no need for 240v service.

Right? Or should I just cool my jets and wait?