ScubaSteve

Well-Known Member

- Joined

- May 21, 2007

- Messages

- 3,673

- Reaction score

- 91

Hey There-

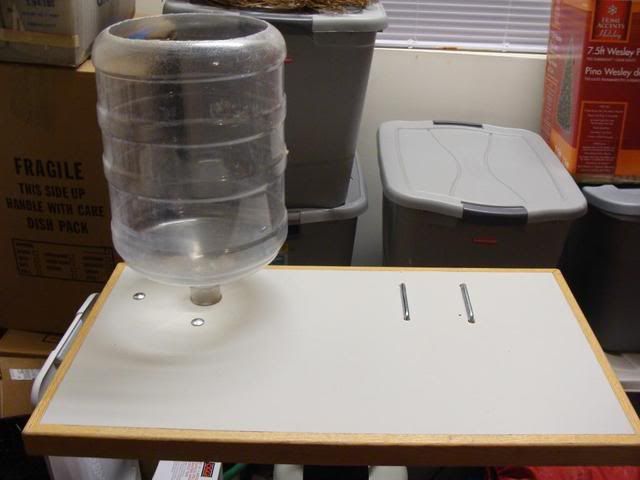

Just got done putting together a rolling mill station, and I thought I'd post a thread of my build. All in all, it came together pretty well and I had a minimum of issues come up during the build. It took me a few hours...lots of eyeballing and measuring, with a minimum of actual work.

I scored this table from work:

It was left out in the snow and destined for the trash, so I gave it a new home! It actually can raise and lower the platform (with some significant strength) via a motor in the base. It's an old motor, but I bet it'd lift 75-100+ lbs. I probably won't test it, because I don't want to spoil a good thing.

Instead, I plan on placing a bucket on the wheeled base, and lowering the mill down onto the bucket. The BC base is still intact, so it still has the rubber feet which fit perfectly into a 5 gal bucket and create a seal against grain dust.

Here's a look at the switch:

It also has a 115v outlet on either end of the base, perfect for plugging in the drill:

Just got done putting together a rolling mill station, and I thought I'd post a thread of my build. All in all, it came together pretty well and I had a minimum of issues come up during the build. It took me a few hours...lots of eyeballing and measuring, with a minimum of actual work.

I scored this table from work:

It was left out in the snow and destined for the trash, so I gave it a new home! It actually can raise and lower the platform (with some significant strength) via a motor in the base. It's an old motor, but I bet it'd lift 75-100+ lbs. I probably won't test it, because I don't want to spoil a good thing.

Instead, I plan on placing a bucket on the wheeled base, and lowering the mill down onto the bucket. The BC base is still intact, so it still has the rubber feet which fit perfectly into a 5 gal bucket and create a seal against grain dust.

Here's a look at the switch:

It also has a 115v outlet on either end of the base, perfect for plugging in the drill: