work from the weekend of 6/4-6/5

Ok, the weekend saw two solid uninterrupted days. So we got alot of work done, but not neccearily a ton of pictures of the work in progress. More like we're done with this piece, here's a pic. So..

The heat deflector plate mounts were welded in. If you recall in an earlier pic, there are two pieces of angle welded across the back. The heat deflector and the grease deflector utilize pins to hold them in place.

Here's a crappy shot of the heat deflector. You can see the rests that are mounted on the walls for the front of the deflector.

Here is the grease deflector on top. It's hard to see, but the pins for this piece poke up through the rear angle. Then there are two cotter pins that hold the deflector in place. They can come out easily so that you can pull the whole thing out for easy clean up. The grease deflector is also larger than the heat deflector, and had angle iron along the edges to catch grease and funnel it towards the front of the smoker and into the grease trap.

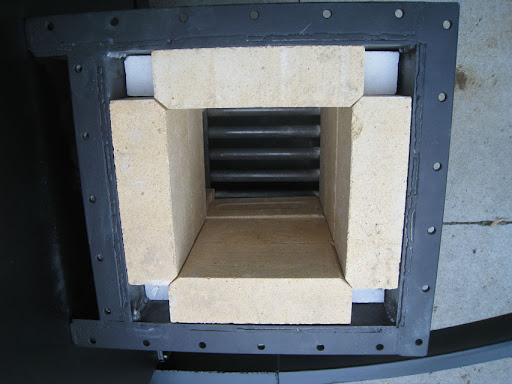

Here's the door getting stuffed. This is the only shot we took with insulation going into it. Need to find a handle for the door, and order a thermo and we'll be good here.

Hey look, our trailer is back together! A little shorter and a lot narrower than before!

And it's about the length of a mazda3 hatch! So it won't take up a ton of room in the driveway.

So a bit has happened by this pic. We cut the legs down on the smoker, and welded on some feet. The smoker is going to be bolted to the trailer now, instead of being welded in. This way in the future, if we decide to take it off the rig, we can. A couple of grade 10 bolts and she won't be going anywhere. We also had the smoker jacked up and on blocks. Had to get the trailer under there somehow. Not like we were going to dead lift it.

Have the trailer slid back and in place. Now it's time to slowly set her down on the frame.

Stacks cut, welded up, and cleaned up.

Just resting in place. Need to weld on some rod so that we can put dampers over them.

At this point, the trailers new feet (well their mates actually) have been welded to the frame and the the smoker is securely bolted to them. The trailer is now up on jack stands. Will be picking up the pieces for the springs tonight, so we can get those and the axle back on.

Now, the frame in the front is where the brewing rig/3 burner stove is going to go. It's just laid on there at the moment. Need to put in some supports for that, but that will come once we get the firebox bolted on and finished up. The firebox door will be opening toward the rear of the brew platform, so we need to account for allowances.