ScubaSteve

Well-Known Member

- Joined

- May 21, 2007

- Messages

- 3,673

- Reaction score

- 91

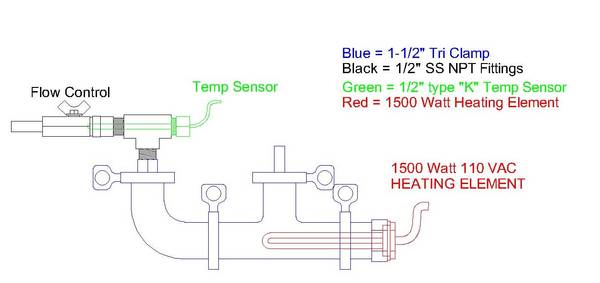

It's nice, but it's another case of the build vs. buy discussion. I refuse to pay $179 for this, but someone else might pony up. This is essentially what I was describing by drilling out an end cap. The beauty of this is that you're not totally effed when the element fails....just drop in a new one.