sammy33

Well-Known Member

I am getting one of these Bayou Classic 44qt steamer kettles with the basket and a spigot for a BIAB setup.

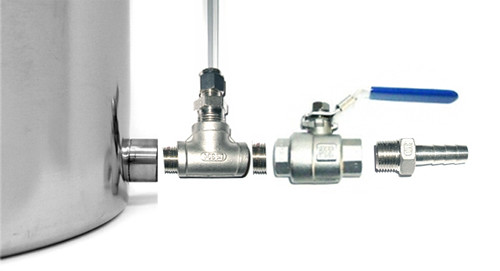

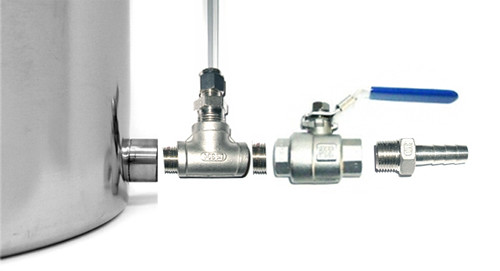

I would like to add a sight glass and a better spigot to the existing weld like this:

I don't foresee any problems with this but wanted to bounce the idea around here to see what you other brewers thought? My goal is to not drill any more holes since it already has a welded fitting.

Wayne at Bargain Fittings mentioned that with this configuration the wort in the sight glass would of course drain as soon as I open the valve. I also thought about aeration of the wort with a sort of a venturi effect? With BIAB style brewing I think this may be a benefit as long as the wort is cooled in the kettle before draining.

I would like to add a sight glass and a better spigot to the existing weld like this:

I don't foresee any problems with this but wanted to bounce the idea around here to see what you other brewers thought? My goal is to not drill any more holes since it already has a welded fitting.

Wayne at Bargain Fittings mentioned that with this configuration the wort in the sight glass would of course drain as soon as I open the valve. I also thought about aeration of the wort with a sort of a venturi effect? With BIAB style brewing I think this may be a benefit as long as the wort is cooled in the kettle before draining.