theveganbrewer

Well-Known Member

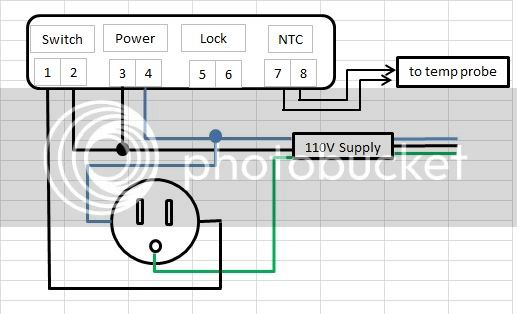

and it Looks like this.

I made the box from AZEK.

Im just testing it now, nothing to brew right now. But in a week or 2, I will be using it in the fridge

Is that a double outlet off one controller? Dang, I should've thought of that