Temp holding update:

I've got it holding steady at 55F, but not sure what an ideal cycling rate is and if the compressor is supposed to be so hot all the time. With the current configuration it's cycling little more than twice an hour: 10 minutes on, 15 minutes off, 10 minutes on, etc. Interior air temps rise about 4F in that 15 minutes, then it takes 10 minutes of the compressor running to bring it back down to the setpoint. Anybody know if this cycling rate is acceptable or if I am shortening the life of the fridge? The compressor doesn't seem to get much of a chance to cool down in that 15 minutes of off time. I could make it cycle less frequently, but of course then the compressor would have to run longer when on. Final question(s): Is there an ideal length of time that a fridge compressor should run? i.e. How long is too long or how short is too short? Would 30 minutes on, 20 minutes off be better?

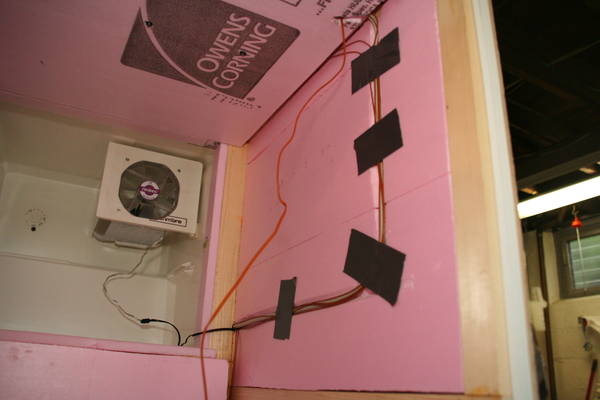

Probe configuration:

I experimented with JohnBeere's idea of placing probe in yeast vile of freezer-pack gel to buffer the probe from fast air temp change, but that dulled controller response too significantly, even with controller hysteresis set to 1 degree; this resulted in wide temp swings. I'm back to using a bare thermocouple probe with 4 degrees of hysteresis in the controller.

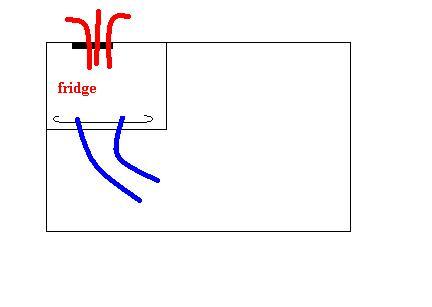

Losses:

Using a cheapy digital IR thermometer ($15 on clearance from RadioShack!), the main area of loss is the gasket between the minifridge and the chamber, particularly on the side near the freezer compartment. Whereas most of the outside of the chamber was about 74F (ambient), that gasket was measuring 66F in same places. In retrospect, I wish I'd encased the sides of the minifridge (heat coils are on the back of this one). I'll come up with a way of addressing this issue (more foam, likely). The front door weather stipping is also a small loss area; about 1 degree lower than ambient around those areas, which seems acceptable.