You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

100 percent home made grain mill

- Thread starter sar_dog_1

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Wow, you built that, looks nice

Thanks! It was a lot of work but hopefully worth it. It took about 6 hours just to knurl the 2 inch steel rollers. All sides were cut on a water jet here at work. Pretty slick!

alien

Well-Known Member

Wow, nice job!

Very cool! That's definitely outside the realm of most home brewers.

Very nice. Home made is a bit of a stretch, unless you've got the most awesome tool shop ever at home.

JoeyChopps

Well-Known Member

sar_dog_1 said:Here is my grain mill I made. It looks like it will work great!

Wow! Can we be friends?

JoeyChopps

Well-Known Member

Ops repost

mrphillips

Well-Known Member

Home shop...work shop...vacation time...vocation time........however you cut it, I'm very impressed. Kudos for not half-a$$ing it. Could it have been made out of wood? Probably, but if given the choice, wouldn't you rather make it out of half inch steel? Yeah - I thought so.

LovesIPA

Well-Known Member

Because everyone has a water jet than can cut through 3/4" aluminum at "home".

It's very cool... but "100% homemade" is a stretch.

It's very cool... but "100% homemade" is a stretch.

You guys are probably fun at parties, I bet

Home made, self made, wtf. Either way the man has mad machining skills - and access to Big Boy Tools that I'd love to have

Looking forward to the rest of the build!

Cheers!

Home made, self made, wtf. Either way the man has mad machining skills - and access to Big Boy Tools that I'd love to have

Looking forward to the rest of the build!

Cheers!

It took about 6 hours just to knurl the 2 inch steel rollers

...

This is me knurling the rollers.

I bet work loved you bump knurling those rollers too

You guys are probably fun at parties, I bet

Home made, self made, wtf. Either way the man has mad machining skills - and access to Big Boy Tools that I'd love to have

Looking forward to the rest of the build!

Cheers!

Like.... tough room today.

Point was I didn't buy it. Geesh!

Mad Mad skills brotha' Nice job for sure. Home made, self made or anyway made, who cares that is one SOLID looking mill! Well done! How are you going to drive it?

Cheers

Jay

Cheers

Jay

Go for the gear box man... Not totally cheep but a much better drive system. I have seen em on Ebay fairly cheep from time to time. I use a 90* gear box on the mill in the store and it is just KILLER we love it! My mill is NO WHERE NEAR as heavy as yours man that is a real nice piece, you should be proud! Did you harden the rollers?

Cheers

Jay

Cheers

Jay

Stealthcruiser

Well-Known Member

?? I made it myself from sctratch at my machine shop at "work".

It's called "OJT"......On the job training..........I'm forced to do it myself sometimes..........

It's called "OJT"......On the job training..........I'm forced to do it myself sometimes..........

I know a fabrication shop owner that when times are a bit slow he will get the boys either making stuff for the shop or doing homers - just so that if a client walks in the shop looks busy instead of everybody lazing around.

You made a true piece of fine craftsmanship. Your beer will be rewarding you.

Can't wait to see the hopper!

Can't wait to see the hopper!

In no way was I disrespecting the craftsmanship or the effort that obviously went into this. It is purely jealousy that I couldn't do his myself at my home (or work) it is very impressive.

Here is my grain mill I made. It looks like it will work great!

I just took a real close look at your mill. Is the driven roll the one you have the eccentric bushing on? If so I think your going to run into problems there with the adjustments on the mill and the adjustments on the drive roll set up.. The eccentric bushing is the non driven roller. At least all the ones I have seen are that way anyway.

Cheers

Jay

Hay where did you end up buying your eccentric bushings from? I think I am going to build me a larger mill for the brewery but I am having a hell of a time finding them.

Cheers

Jay

Cheers

Jay

Hay where did you end up buying your eccentric bushings from? I think I am going to build me a larger mill for the brewery but I am having a hell of a time finding them.

Cheers

Jay

i used 1 3/8 steel round stock, cut half inch thick and drilled a 5/8 hole 3/8 off center to fit the bushing. I also drilled a set screw in it to secure the bushings. The aluminum sides are 3/4" so i drilled a 15/16 hole in the bottom of the 1 3/8 insert to allow for the other 1/4 of the bushing to ride in.

Hope this helps! Cheer!!

motobrewer

I'm no atheist scientist, but...

nice work.

can somebody post some links to gearboxes?

can somebody post some links to gearboxes?

brieuxster

Well-Known Member

Your mill is bigger than mine.... nice work https://www.youtube.com/watch?v=a0pD52ChpHk

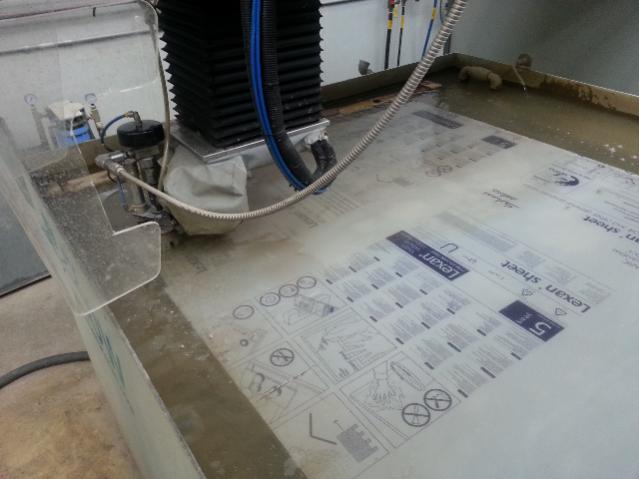

sar_dog_1 said:Ok. Just finished the hopper. 3/8 lexan. I can't wait to start the drivetrain!

Looking good, have you decided what you are going to power it with? Can't wait to see it in action

sar_dog_1 said:I have a 3/4hp ac motor. I just need to get a 6, 8, 2, 2 pullys and do a double reduction to put me at exactly 143 rpms. Or 15 ft per second. Ideal crush speed from what I understand.

Sweet, have is mentioned that I can't wait to see the finished product, dude this really a sweet DIY. Really wish I had access to the tools and experience you obviously have, you know you are going to have to give it a cool name like the Mighty Crush O'Matic, paint teeth on the hopper.

I have a 3/4hp ac motor. I just need to get a 6, 8, 2, 2 pullys and do a double reduction to put me at exactly 143 rpms. Or 15 ft per second. Ideal crush speed from what I understand.

15 feet per sec is ideal? Where did you get that from?

Assuming your rollers are 2" diameter (1" radius):

143 rpm = 143 / 60 rps = 143*2*3.14*1 / 60 ips = 15 ips (inch per second).

[EDIT] Although it may be sacrilegious to buy anything, there are 10:1 gear reduction boxes out there.

JustLooking

Well-Known Member

- Joined

- Dec 31, 2009

- Messages

- 638

- Reaction score

- 125

Grain is pretty abrasive. I wonder what this will look like 12 months from now?I decided to make my hopper out of 3/8 lexan. Thought it might be cool to see the milling in action.

Your right. Inches per second. I did a google search and found what sounded reputable for speed. I figured good enuff and went with it. Right now I am on the lookout for free pullys so may take a while. I will deff post a vid when I am done.

Similar threads

- Replies

- 6

- Views

- 816