andrewprime1

Active Member

- Joined

- Jul 28, 2014

- Messages

- 30

- Reaction score

- 5

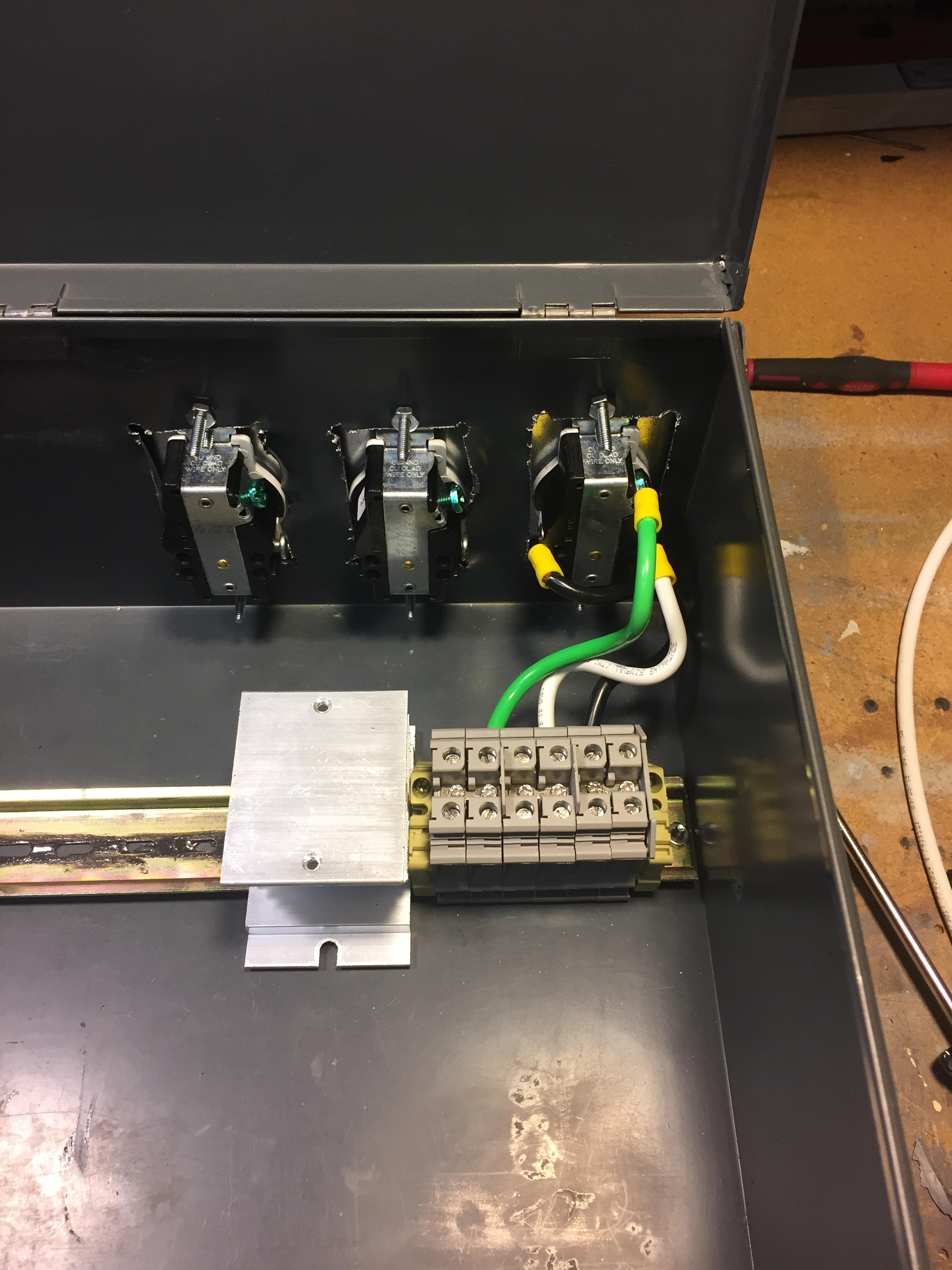

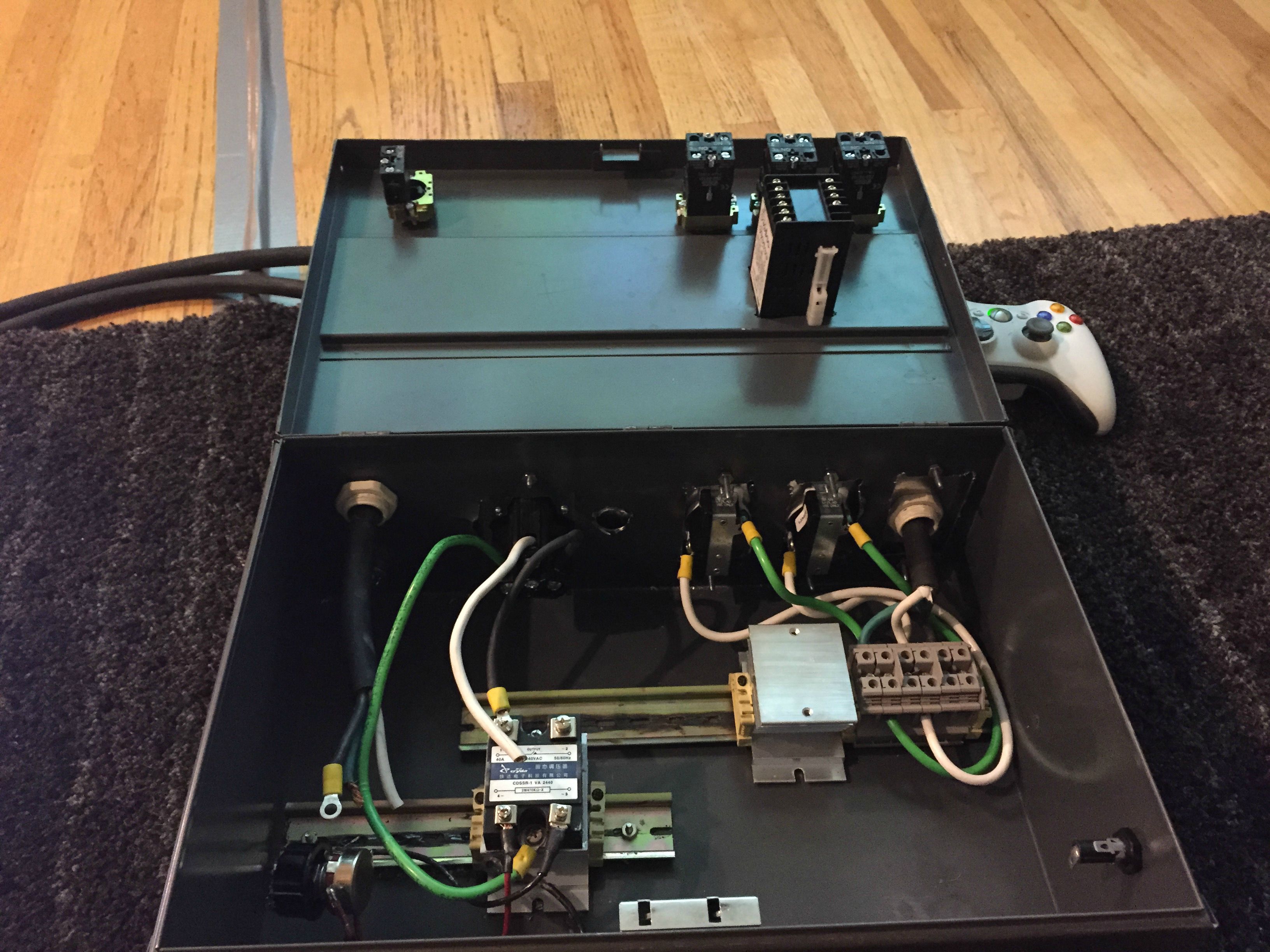

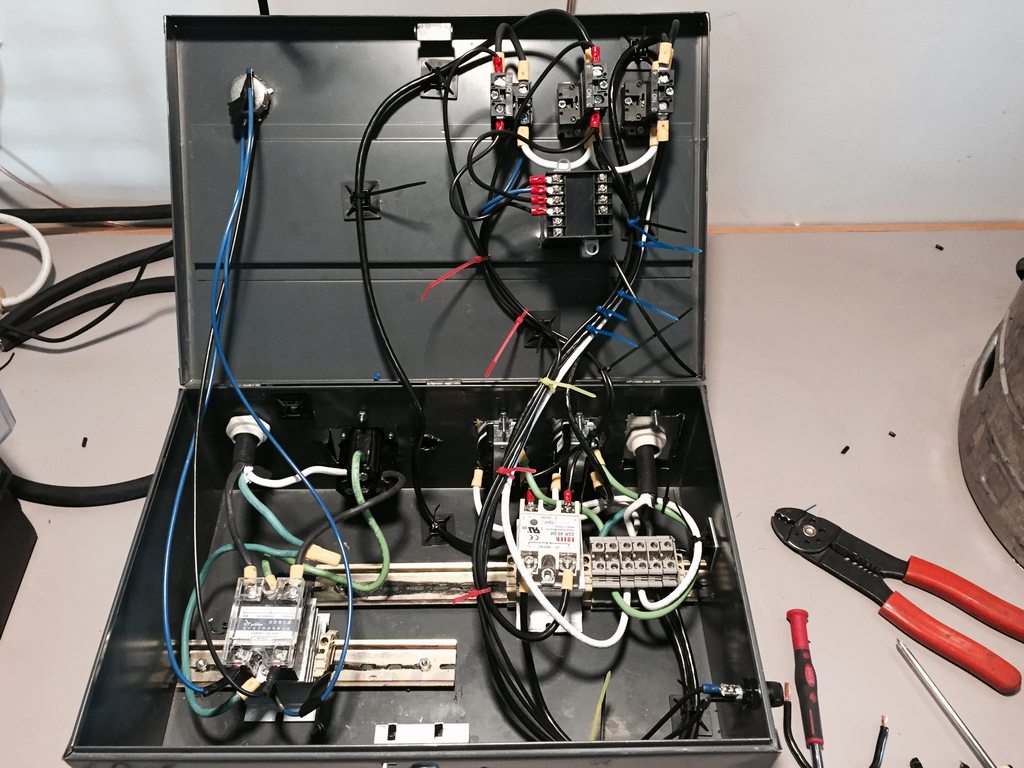

I have had my StillDragon controlled 240v BK running BIAB for a while now, and boy is it an improvement over hauling all my **** out onto the front porch, running out of propane, long heating times, etc. But low efficiency and a chronic need to project have got me ready to make the jump to a RIMS tub setup!

Here is the BK in all her glory!

View attachment ImageUploadedByHome Brew1430321178.856653.jpg

What I want is a nice, simple, two vessel system. I will leave the BK to be controlled by the StillDragon potentiometer and have the MT controlled by one element running at 120v controlled by one PID. Heat water in BK, pump in to MT, maintain temp with RIMS tube. Simple.

Here is what I have so far -

Sanke Keg (obtained legally)

Chugger Pump

An 18”x12” metal box I scored from savers for like 8 bucks!

View attachment ImageUploadedByHome Brew1430321439.304114.jpg

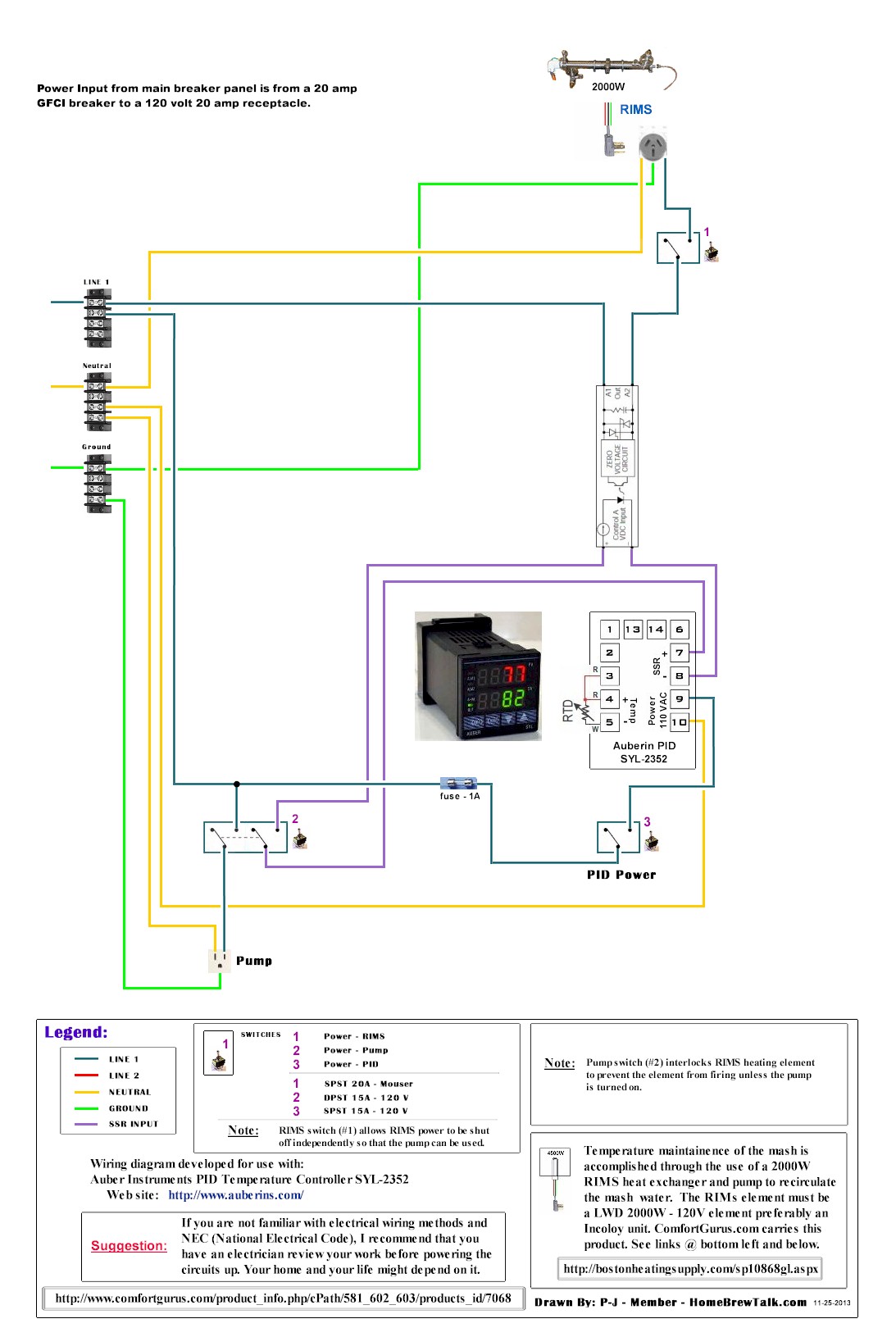

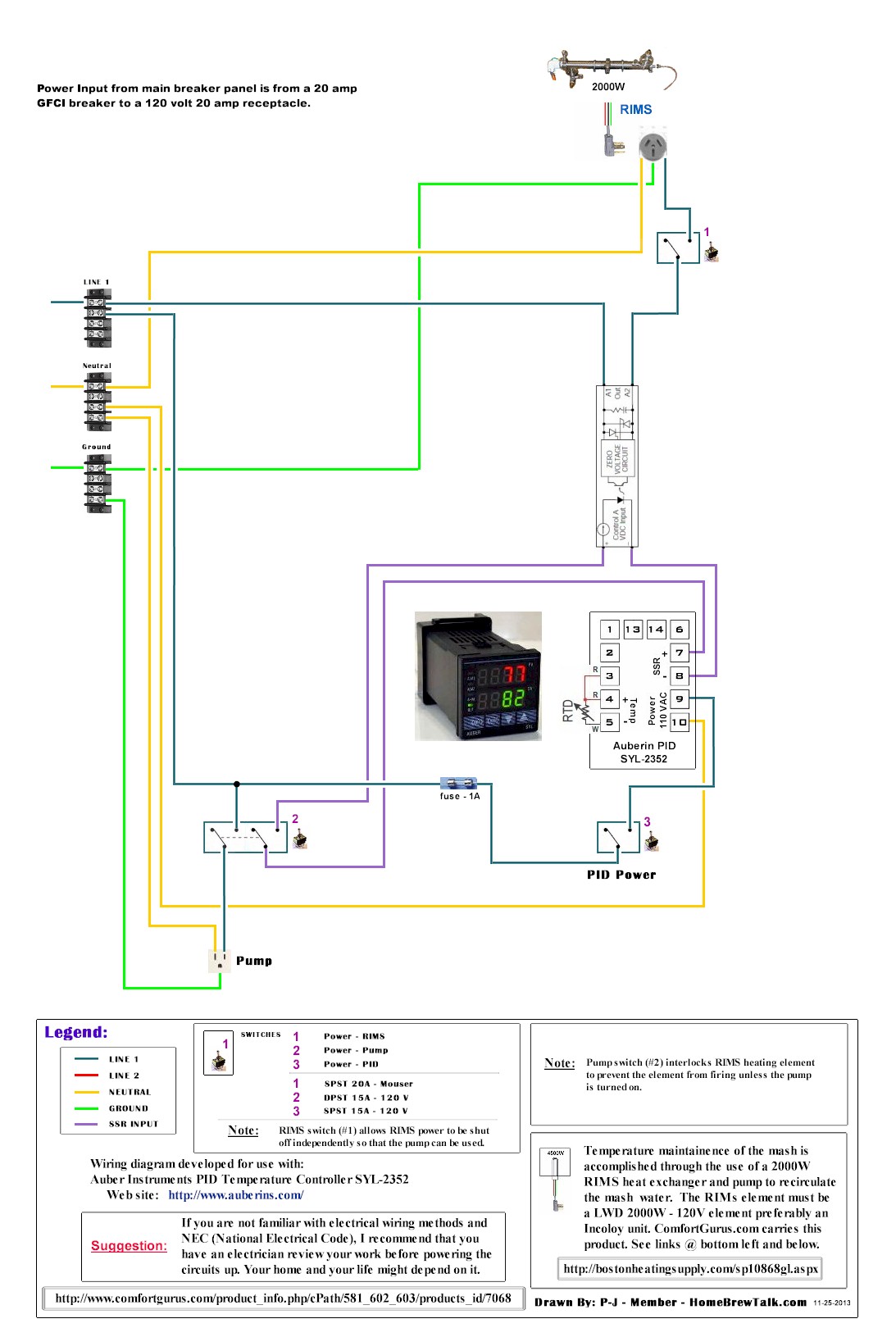

I found this diagram (thanks P-J) and based my parts list on it.

I have done lots of studying and think that the parts list I have compiled is right, but I could always use another set of (more talented) eyes to make sure.

NIXED THESE FOR LOWER COST ITEMS -

Auber PID SYL-2352 - $46.50

eBrewSupply 40amp SSR & Heatsink - $15.50 Total

Auber Liquid-tight K type, 2 in probe, 1/4" NPT Thread - $21.95

Instead, went with -

eBay MYPIN TD4-SNR w/ 40amp SSR - $35.99

And-

eBay RTD PT100 Temperature Sensor & Detachable Connector - $14.99

eBrewSupply LED Two Way Switch - $8.00 (3x)

eBrewSupply 1/2 Meter DIN Rail Cut - $3.00

eBrewSupply Terminal Blocks - $1.20 (6x)

eBrewSupply Terminal Block Separator - $1.00 (2x)

eBrewSupply Terminal End Caps - $1.00 (2x)

eBrewSupply Terminal Block End Block - $2.00 (2x)

eBrewSupply DIN Rail Terminal Bridge $2.50

Plus, of course -

4 Colors 10 Gauge Wire - 5’/ea

10 Gauge Spade Terminals - a bunch

Brew Hardware RIMS Tube - 12” w/ Camlocks - $149.99

Brew Hardware 2000w LWD SS Element - $29.99

I think this is everything! The only thing in unsure of is the switches.. In the diagram, the #2 switch that controls the pump has six posts, I assume this is because it interrupts power to the element of the pump isn't on. I think the switches I am getting don't have that many post, so is an add on contact my solution? Should I get a NO or NC contact? Are they compatible with these switches?

Here is the BK in all her glory!

View attachment ImageUploadedByHome Brew1430321178.856653.jpg

What I want is a nice, simple, two vessel system. I will leave the BK to be controlled by the StillDragon potentiometer and have the MT controlled by one element running at 120v controlled by one PID. Heat water in BK, pump in to MT, maintain temp with RIMS tube. Simple.

Here is what I have so far -

Sanke Keg (obtained legally)

Chugger Pump

An 18”x12” metal box I scored from savers for like 8 bucks!

View attachment ImageUploadedByHome Brew1430321439.304114.jpg

I found this diagram (thanks P-J) and based my parts list on it.

I have done lots of studying and think that the parts list I have compiled is right, but I could always use another set of (more talented) eyes to make sure.

NIXED THESE FOR LOWER COST ITEMS -

Auber PID SYL-2352 - $46.50

eBrewSupply 40amp SSR & Heatsink - $15.50 Total

Auber Liquid-tight K type, 2 in probe, 1/4" NPT Thread - $21.95

Instead, went with -

eBay MYPIN TD4-SNR w/ 40amp SSR - $35.99

And-

eBay RTD PT100 Temperature Sensor & Detachable Connector - $14.99

eBrewSupply LED Two Way Switch - $8.00 (3x)

eBrewSupply 1/2 Meter DIN Rail Cut - $3.00

eBrewSupply Terminal Blocks - $1.20 (6x)

eBrewSupply Terminal Block Separator - $1.00 (2x)

eBrewSupply Terminal End Caps - $1.00 (2x)

eBrewSupply Terminal Block End Block - $2.00 (2x)

eBrewSupply DIN Rail Terminal Bridge $2.50

Plus, of course -

4 Colors 10 Gauge Wire - 5’/ea

10 Gauge Spade Terminals - a bunch

Brew Hardware RIMS Tube - 12” w/ Camlocks - $149.99

Brew Hardware 2000w LWD SS Element - $29.99

I think this is everything! The only thing in unsure of is the switches.. In the diagram, the #2 switch that controls the pump has six posts, I assume this is because it interrupts power to the element of the pump isn't on. I think the switches I am getting don't have that many post, so is an add on contact my solution? Should I get a NO or NC contact? Are they compatible with these switches?

they are great. You built your brewery to your liking and that's great. Who cares how much mine will cost though? I mean, people spend this much having an electrician put in 220, people buy $30 locking plugs with matching $30 outlets. I think this is relatively cheap, honestly.

they are great. You built your brewery to your liking and that's great. Who cares how much mine will cost though? I mean, people spend this much having an electrician put in 220, people buy $30 locking plugs with matching $30 outlets. I think this is relatively cheap, honestly.