pilotdane

Well-Known Member

Any idea how much oxygen (flow rate, time) is a good starting point when using a .5 micron stone in a 5 gallon batch?

Oxygenate is a better word to use.

I use 1-2min for a 5gal batch. Sometimes less cuz Star San foams like mad.

Where did you get the regulator? I've been wanting to do oxygen, but I'm not real excited about using the disposable canisters.

I'm sure he's talking about residual starsan foam in the carboy.

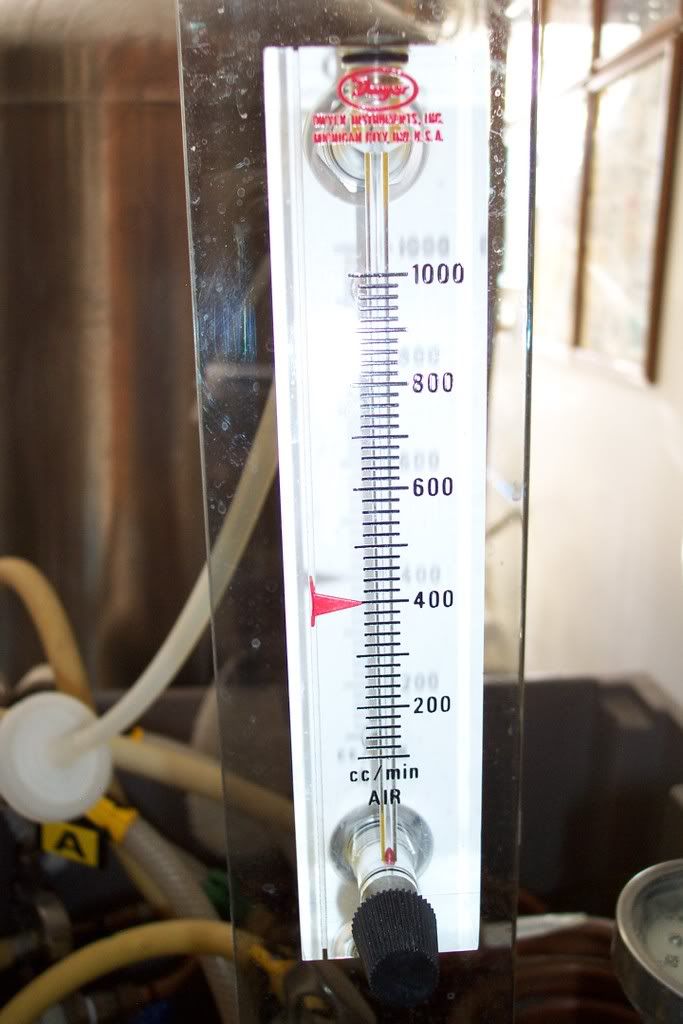

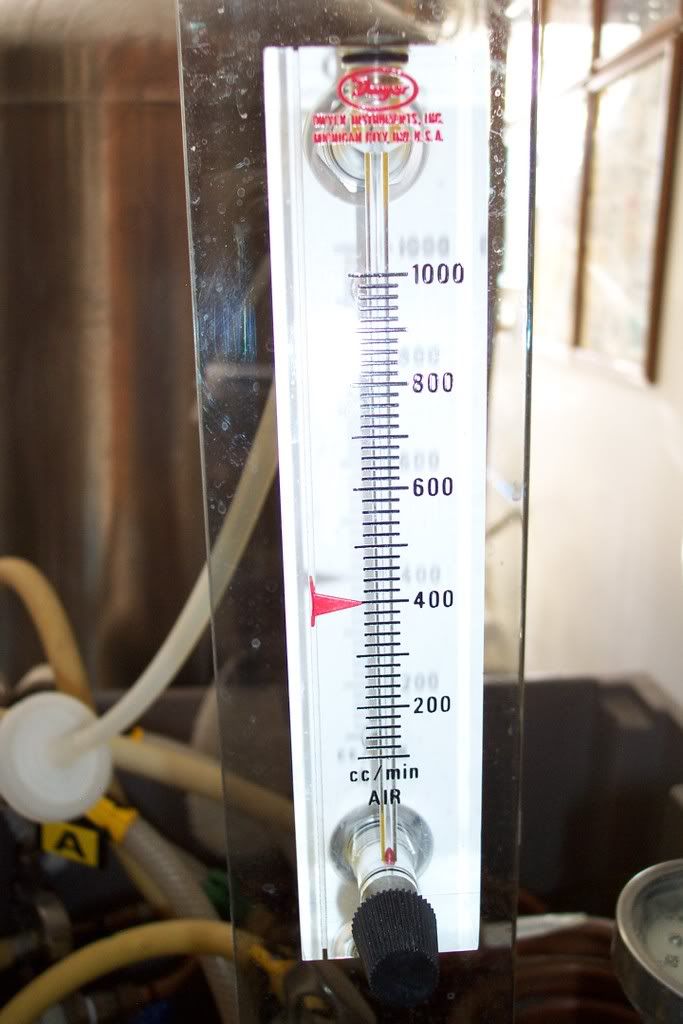

For my setup the flow rate is set to 300cc/m at 20 PSI, gives me the least amount of foaming.Any idea how much oxygen (flow rate, time) is a good starting point when using a .5 micron stone in a 5 gallon batch?

For my setup the flow rate is set to 300cc/m at 20 PSI, gives me the least amount of foaming.

Above 400 mostly foam.

The oxygenation takes as long as the chilling takes, no fixed time.

I use a standard welding tank and regulator with a Dwyer adjustable flow meter.

Adjustable flow meter.

Cheers,

ClaudiusB

Isn't this going to displace you nice pure medical grade oxygen with air (which is 70% nitrogen)?....then I bung the carboy, and rock (shake) it really good to get more of the O2 into solution....seems to work good that way ....

Isn't this going to displace you nice pure medical grade oxygen with air (which is 70% nitrogen)?

I am about to buy a oxygen cylinder and regulator but thought the regulator could tell me how much O2 I am putting in. Do I need a flow meter like you have too? Where in the line is that at too?

...every single time I oxygenate I get massive continuous blow off for 2 or 3 days that covers the entire fermenter! It's ridiculous and I'm getting tired of cleaning it up!

Indeed, anyone who has the classic style regulator (PSI) and a flow meter that reads in L/m. Could you give us an idea of what PSI correponds to a given flow rate, and be sure to mention whether you have a 0.5 or a 2 um stone. Then we will be able to get into the ballpark pressure without having to invest in a flowmeter or a DO meter. thanks for your input!

I think you will find it hard to apply the correct amount of o2 consistently. Most people set the dial to only 2-3 psi when injecting o2... that will be pretty hard to read on this scale.

Aerating worth prior to fermentation is good. You can do this by splashing the worth around, shaking the bucket, using an aquarium pump, or adding oxygen.

Using oxygen is the fastest way to do it.

Enter your email address to join: