Cregar

Well-Known Member

OK... starting my first DIY project for a fermentation chiller. I have found the plans online and seen some of the ones here on the site.

I decided to double the size of the plans I found online so I could hold 3 or 4 carboys.

I had a couple of questions... on the plans it says to cut 2 square area out of the piece between where the ice goes and where the carboys are, but it says to only use 1 fan. why is that?

Also, since cold air drops to the floor... wouldn't it be better to have the fans at the bottom of the chiller then at the top?

Would it work to have a fan on the bottom blowing air into the carboy chamber and one fan at the top, sucking air out... in effect, circulating the air?

Please... any advice or input would be appreciated.

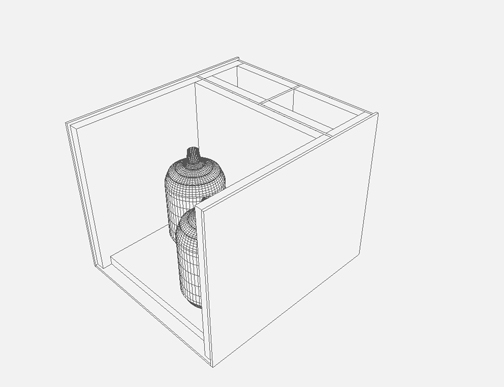

BTW... here is a rough design so far.

Measurments are:

Width: 36"

Height: 33"

Depth: 41"

It will be made with Omega board that I can get from work and have 2" Polystyrene for insulation inside.

UPDATE: I might have to make the width a little smaller... just measured and it won't fit through my front door.

I decided to double the size of the plans I found online so I could hold 3 or 4 carboys.

I had a couple of questions... on the plans it says to cut 2 square area out of the piece between where the ice goes and where the carboys are, but it says to only use 1 fan. why is that?

Also, since cold air drops to the floor... wouldn't it be better to have the fans at the bottom of the chiller then at the top?

Would it work to have a fan on the bottom blowing air into the carboy chamber and one fan at the top, sucking air out... in effect, circulating the air?

Please... any advice or input would be appreciated.

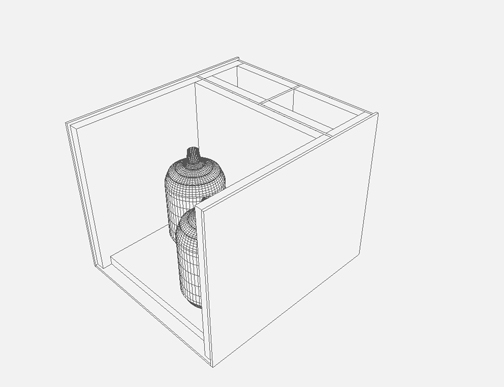

BTW... here is a rough design so far.

Measurments are:

Width: 36"

Height: 33"

Depth: 41"

It will be made with Omega board that I can get from work and have 2" Polystyrene for insulation inside.

UPDATE: I might have to make the width a little smaller... just measured and it won't fit through my front door.