They do not use a HERMS brewing system

My set up is not a HERMS or a RIMS system and requires a mash mixer.

I installed mash mixers in both of my mash tuns for the following reasons:

1. Direct fired

2. Step mashing

3. No brewer required to stir during mashing, process automated

The mash tuns are combination Mash/Lauter and require a mash-out rest with the mixer off for the grain bed to settle.

After the rest a normal vorlauf clears the wort.

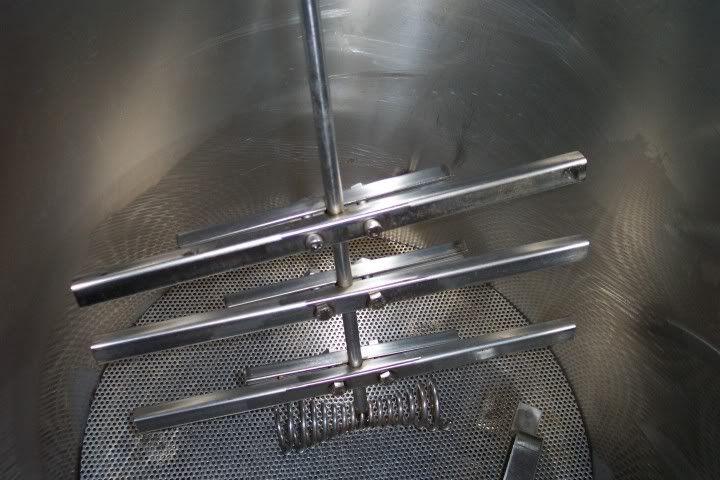

200 liter two position mash tun mixer.

One position is for mashing and the second is for clean-out (grain dump).

During grain dumping

50 liter mash tun mixer

Cheers,

ClaudiusB