Roadie

Well-Known Member

Ok I need some help. We've moved to the south where basements don't exist due to elevation (Charleston, SC is 12' above sea level) so I'm now forced to become a garage brewer. We have a 2 car garage that's finished - meaning it has walls and a ceiling and painted to look nice. The breaker panel is in the garage and is flush mounted into the wall. I need to run a new electrical circuit/line from the panel to the opposite (parallel) wall where the brewery will be set up. I don't want to mess up the drywall to do this so plan on using .5" metal conduit (EMT) with the 10 gauge wires inside ran along the ceiling and down to a surface mounted metal box and then paint the conduit to match the wall color.

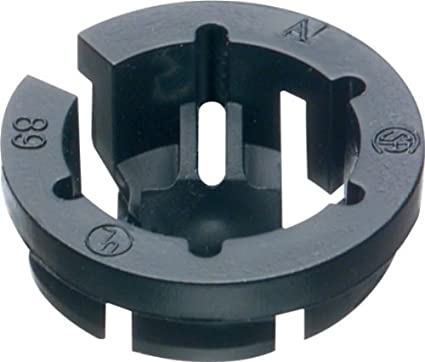

I've never ran conduit before (used romex in the basement for the old brewery but it was unfinished when we started so easy to do) and am puzzled how to connect it to the new breaker in the panel. Do I make a hole in the drywall by the panel and place a surface mounted box there with the wires coming in the back and conduit hooking into the side of that box? If so, do I simply use it as a pass through, or do I pigtail off inside the box to the wires running to the other side of the garage making this a true junction box? If not, what method do I use to connect the conduit to the box?

Any and all ideas/suggestions are appreciated.

I've never ran conduit before (used romex in the basement for the old brewery but it was unfinished when we started so easy to do) and am puzzled how to connect it to the new breaker in the panel. Do I make a hole in the drywall by the panel and place a surface mounted box there with the wires coming in the back and conduit hooking into the side of that box? If so, do I simply use it as a pass through, or do I pigtail off inside the box to the wires running to the other side of the garage making this a true junction box? If not, what method do I use to connect the conduit to the box?

Any and all ideas/suggestions are appreciated.