ingchr1

Well-Known Member

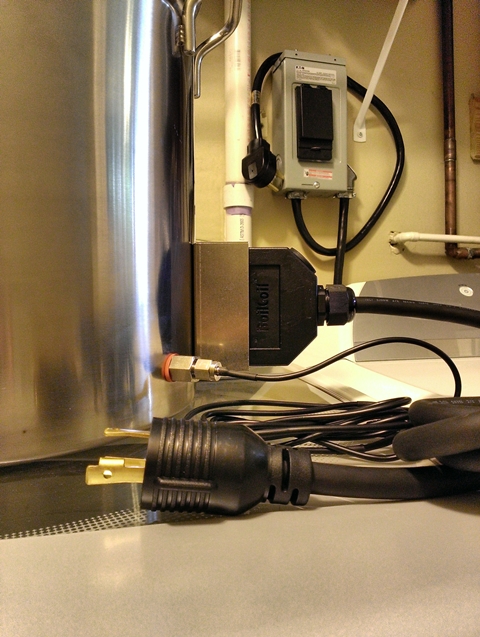

I just got a Brew Boss controller, so I thought I'd start a thread on it. The Brew boss is the new system from the creator of the picoBrew E-BAIB system. Where the picoBrew was specific to BIAB, the Brew Boss is user customizable to just about any brew process and is controlled via an Android tablet app. The website (brew-boss.com) has a lot more information on it. I did not get a complete system. I got the DIY controller (minus Android tablet) and a weldless probe adapter. I plan on using it on a two vessel system. Combination BK/HLT with cooler MLT, gravity drain first runnings, pump the rest. I currently have a three vessel system (Link to my current system in the Show me your brew rig thread).

I was one of the people who discussed making the picoBrew more universal with the creator. As mentioned in other threads, he was very responsive to all my questions and suggestions. Most of all he went ahead and created this system and offered me one prior to its release.

Unfortunately, I probably wont get to brew with it for at least a few weeks as I'm still building my system. I need an Android tablet, spa panel and I'm awaiting the release of the Blichmann Boil Coil. I hope to have a tablet soon, so I can at least mess around with the app.

Hopefully others will get this system, brew with it sooner than I'm going to and contribute to this thread on it.

I was one of the people who discussed making the picoBrew more universal with the creator. As mentioned in other threads, he was very responsive to all my questions and suggestions. Most of all he went ahead and created this system and offered me one prior to its release.

Unfortunately, I probably wont get to brew with it for at least a few weeks as I'm still building my system. I need an Android tablet, spa panel and I'm awaiting the release of the Blichmann Boil Coil. I hope to have a tablet soon, so I can at least mess around with the app.

Hopefully others will get this system, brew with it sooner than I'm going to and contribute to this thread on it.