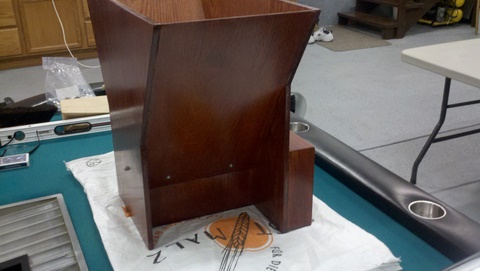

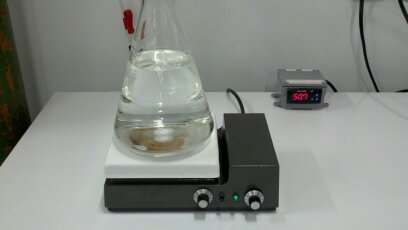

Well I guess I need to get my post up before I can share my pictures of my electric brewery. Its a Kal clone with some differences. I just finished the matching Grain Mill and I'm currently working on my matching exhaust hood. Hope to share the pictures soon. Happy Holidays to everyone, Castermmt