Howhownow

Well-Known Member

Hello!

It's been a minute (~6+ months) since I have been active on HBT and brewing at all due to my recent purchase of an 85 year old house. I decided to put brewing on the back burner while I got everything fixed up, but to always keep it in mind with my home improvement plans.

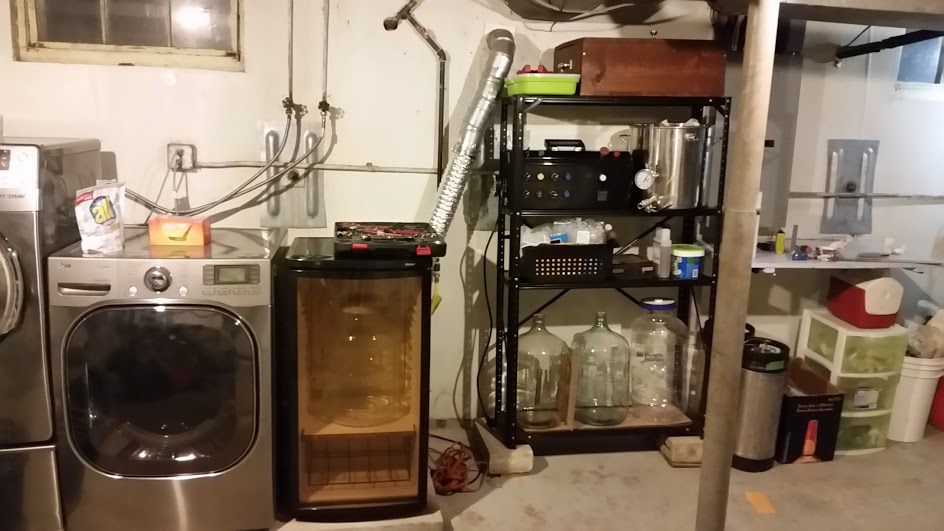

Long story short, all of the big work is done, and I finally got my shed put in a few weeks ago to convert a single space (basement) that was unusably cluttered with both tools and brew gear to two very functional spaces. Workshop in the shed, brewery in the basement.

I chose that setup for many reasons, the main ones being access to water/ electric in the basement, and the convenience if being able to brew without ever leaving the house. That said, brewing in a basement will create its own set of challenges (will cover later).

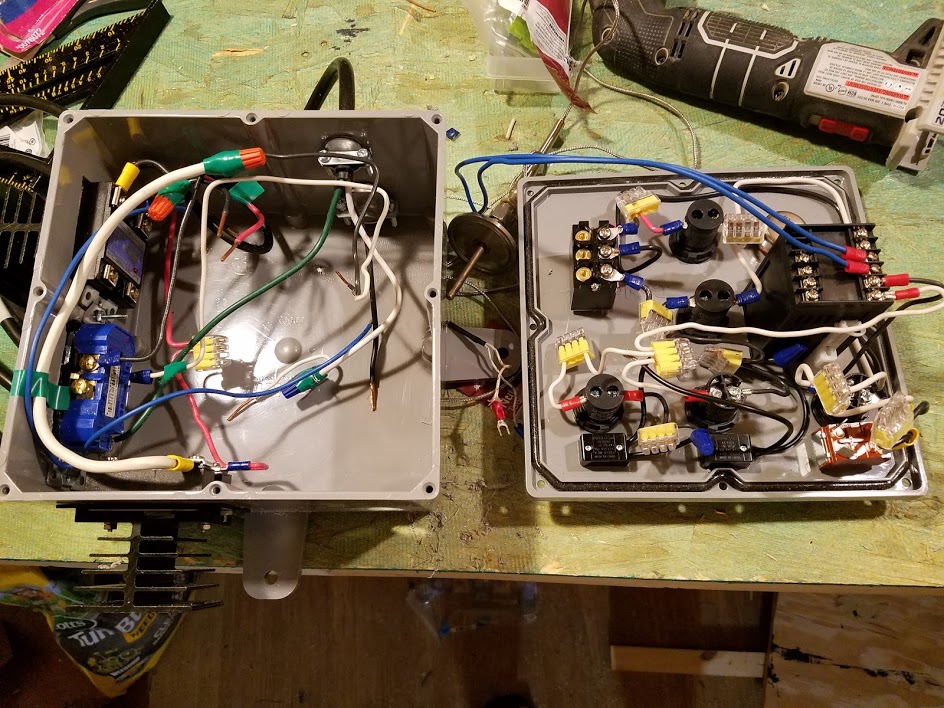

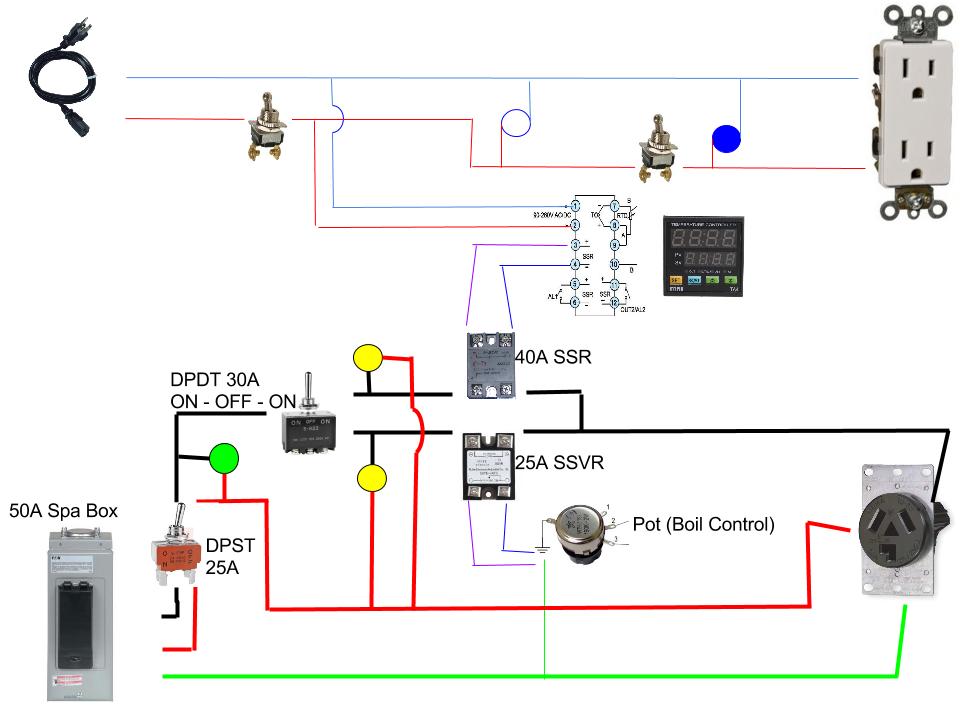

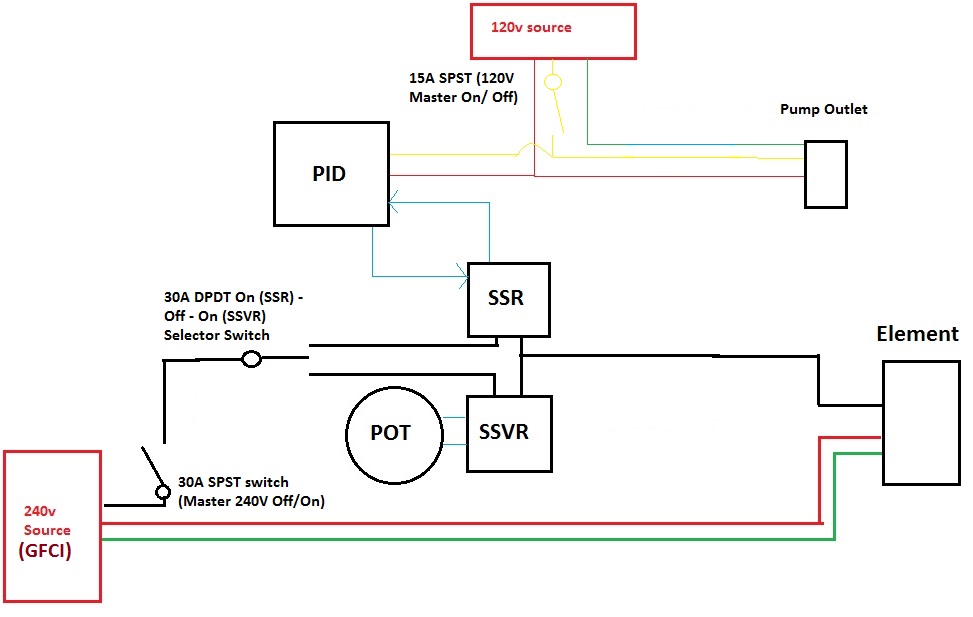

I also am choosing to overhaul my whole setup and process. I am currently running a hybrid LP (boil)/Electric (mash via RIMS tube) 3 vessel tiered system, using both gravity and a pump. I'm brewing in 5 gallon batches. I'm brewing good beer, but it's a lot of moving parts and a PITA to set up and clean out. It also has a big footprint. I'm selling everything except my burner, RIMS tube, and control box and starting fresh. My new goal is 5 OR 10 gal batch flexibility in a single-vessel, no sparge BIAB to cut down on size, brew time, and cleanup. I intend to keep my RIMS Mash and gas boil approach, though convert to NG (already run in the basement). After much (MUCH) planning, research, and design, I decided to with the Colorado Brewing Systems Single vessel BIAB system. For features, quality, flexibility, and value they just couldn't be beat. I am currently in the process of getting that specced out and ordered (excellent customer support over there, FYI). The plan is to build a wooden pedestal that the burner and kettle will sit atop, and to the front of that I'll mount my RIMS tube, pump, potentially a plate chiller(TBD). I'll bring my strike to temp with either/both burner/RIMS. Add my grain, recirc using pump and RIMS, winch grain basket, boil with burner, whirlpool, chill.

Whew... that was all really long winded, but it was good to write it all out. To summarize:

Challenges:

- Low ceilings (~7'+) covered in 80 years of layered gas, water, electrical work

- While floor generally slopes towards sump, that slope is variable (especially near walls)

- Walls are generally unsuitable to mount things on due to existing waterproofing measures.

- Want to keep system and gear organized and laid out efficiently and attractively. It is not a finished or pretty basement, but I don't want unsightly and potentially dangerous clutter messing with brew day

- My main electrical service breaker is basically right in the middle of the main wall

Remaining projects that I hope to document here:

- Build brew stand (pedestal)

- Build ventilation system

- Plumb GIGANTIC new (to me) utility sink, avoiding existing electrical stuff and not mounting to wall

- Convert burner (Bru Burner) to NG

- Put everything together and order balance of fittings, hoses, etc.

- Figure out my chiller strategy

- Recalibrate controller

- BREW (maybe someday)

If anyone has any suggestions, tips, etc... fire away!

Stay tuned for pictures of old system and some 'before' shots.

--

It's been a minute (~6+ months) since I have been active on HBT and brewing at all due to my recent purchase of an 85 year old house. I decided to put brewing on the back burner while I got everything fixed up, but to always keep it in mind with my home improvement plans.

Long story short, all of the big work is done, and I finally got my shed put in a few weeks ago to convert a single space (basement) that was unusably cluttered with both tools and brew gear to two very functional spaces. Workshop in the shed, brewery in the basement.

I chose that setup for many reasons, the main ones being access to water/ electric in the basement, and the convenience if being able to brew without ever leaving the house. That said, brewing in a basement will create its own set of challenges (will cover later).

I also am choosing to overhaul my whole setup and process. I am currently running a hybrid LP (boil)/Electric (mash via RIMS tube) 3 vessel tiered system, using both gravity and a pump. I'm brewing in 5 gallon batches. I'm brewing good beer, but it's a lot of moving parts and a PITA to set up and clean out. It also has a big footprint. I'm selling everything except my burner, RIMS tube, and control box and starting fresh. My new goal is 5 OR 10 gal batch flexibility in a single-vessel, no sparge BIAB to cut down on size, brew time, and cleanup. I intend to keep my RIMS Mash and gas boil approach, though convert to NG (already run in the basement). After much (MUCH) planning, research, and design, I decided to with the Colorado Brewing Systems Single vessel BIAB system. For features, quality, flexibility, and value they just couldn't be beat. I am currently in the process of getting that specced out and ordered (excellent customer support over there, FYI). The plan is to build a wooden pedestal that the burner and kettle will sit atop, and to the front of that I'll mount my RIMS tube, pump, potentially a plate chiller(TBD). I'll bring my strike to temp with either/both burner/RIMS. Add my grain, recirc using pump and RIMS, winch grain basket, boil with burner, whirlpool, chill.

Whew... that was all really long winded, but it was good to write it all out. To summarize:

Challenges:

- Low ceilings (~7'+) covered in 80 years of layered gas, water, electrical work

- While floor generally slopes towards sump, that slope is variable (especially near walls)

- Walls are generally unsuitable to mount things on due to existing waterproofing measures.

- Want to keep system and gear organized and laid out efficiently and attractively. It is not a finished or pretty basement, but I don't want unsightly and potentially dangerous clutter messing with brew day

- My main electrical service breaker is basically right in the middle of the main wall

Remaining projects that I hope to document here:

- Build brew stand (pedestal)

- Build ventilation system

- Plumb GIGANTIC new (to me) utility sink, avoiding existing electrical stuff and not mounting to wall

- Convert burner (Bru Burner) to NG

- Put everything together and order balance of fittings, hoses, etc.

- Figure out my chiller strategy

- Recalibrate controller

- BREW (maybe someday)

If anyone has any suggestions, tips, etc... fire away!

Stay tuned for pictures of old system and some 'before' shots.

--

:rockin::fro:

:rockin::fro: