I have been toying around the idea to switch to electric brewing for a couple months after reading all of the people building their systems. It came to a reality when I pinched a nerve in my back lifting a pot of wort. It was the justification I needed to get my swimbo's approval.

I need to thank a couple of people for inspiration on this endeavor. PJ for your generosity in providing the wiring schematics that so many have used, to Kal from The Electric Brewery for his detailed build along with the many HBT'ers that have built and are currently building their electric systems that shared their builds.

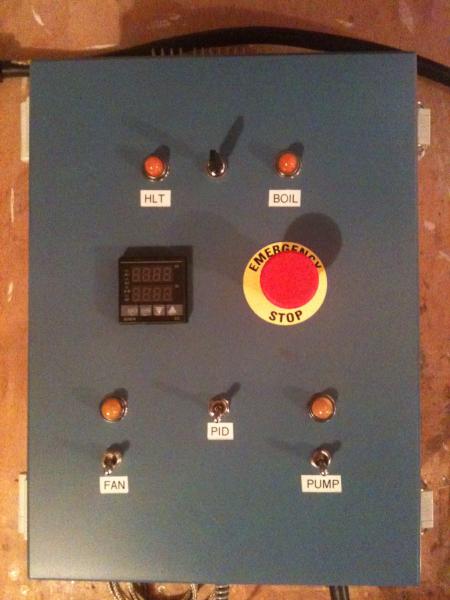

I decided on a 3 vessel single tier system that uses 2 4500W ULWD elements controlled by 1 PID and 1 pump. I dont mind switching hoses for now to keep costs manageable.

I had my 50amp GFI spa panel installed by a licensed electrician to a 30 amp breaker in the main panel. In the spa panel is a 4 wire outlet.

I do not have a garage so I have set up my system in my basement. I plan on making a simple exhaust hood powered by an 8 inline fan that will be made to fit in the basement window to handle the moisture issue.

The single tier system will be on a 30 x 60 table that was surplus at my work.

I started ordering material 3 weeks ago and I am almost complete. Whats left to do is mount the elements (waiting on SS nuts), wire the elements, complete the herms coil and then work on the ventilation.

Pictures to follow

I need to thank a couple of people for inspiration on this endeavor. PJ for your generosity in providing the wiring schematics that so many have used, to Kal from The Electric Brewery for his detailed build along with the many HBT'ers that have built and are currently building their electric systems that shared their builds.

I decided on a 3 vessel single tier system that uses 2 4500W ULWD elements controlled by 1 PID and 1 pump. I dont mind switching hoses for now to keep costs manageable.

I had my 50amp GFI spa panel installed by a licensed electrician to a 30 amp breaker in the main panel. In the spa panel is a 4 wire outlet.

I do not have a garage so I have set up my system in my basement. I plan on making a simple exhaust hood powered by an 8 inline fan that will be made to fit in the basement window to handle the moisture issue.

The single tier system will be on a 30 x 60 table that was surplus at my work.

I started ordering material 3 weeks ago and I am almost complete. Whats left to do is mount the elements (waiting on SS nuts), wire the elements, complete the herms coil and then work on the ventilation.

Pictures to follow