Downey26

Pig Pen Brewery

- Joined

- Aug 2, 2015

- Messages

- 25

- Reaction score

- 4

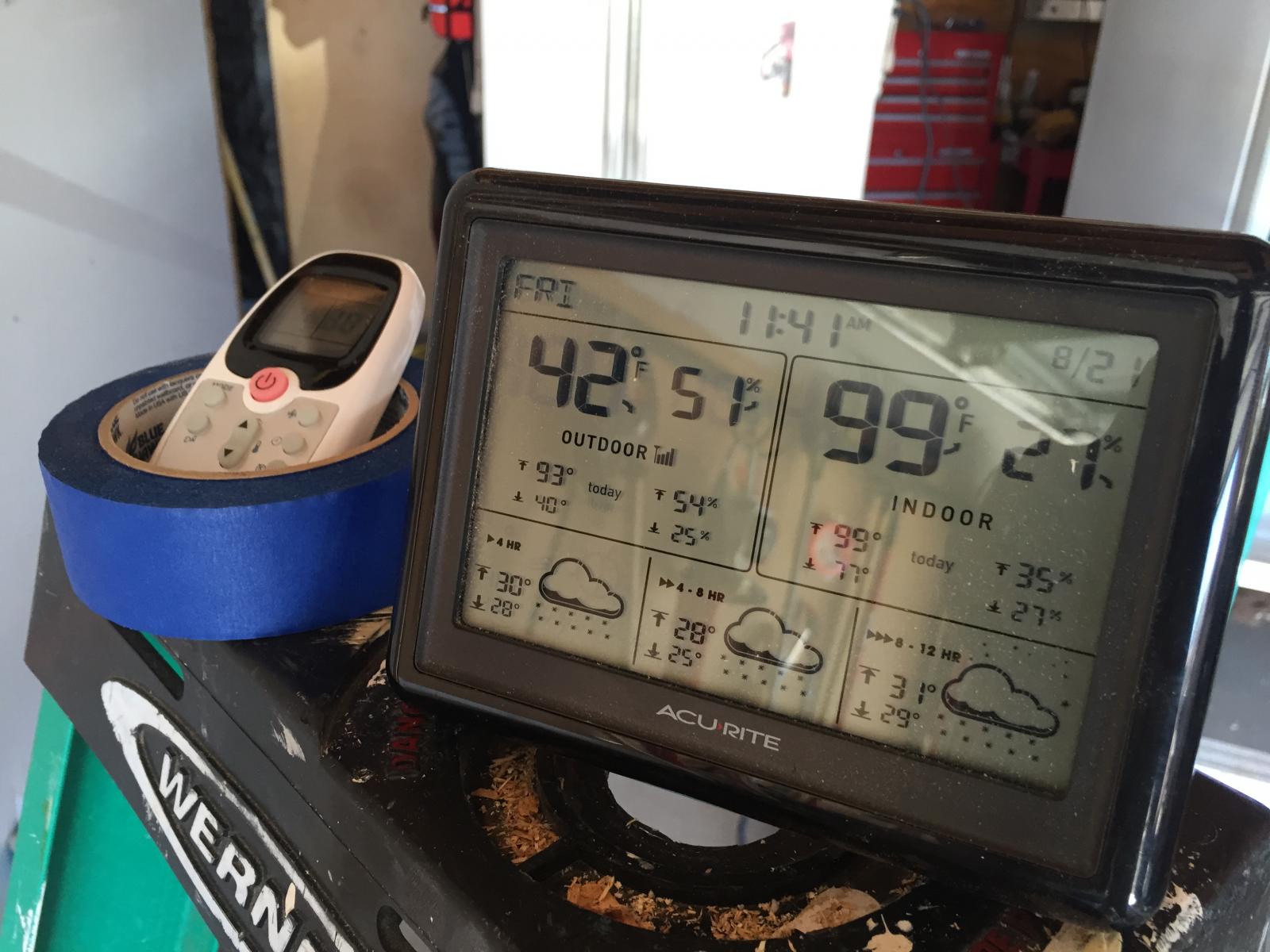

I am building a walk in cooler inside my garage. It will be 8x4x7. I got a lot of good idea's from everyone on here so i thought i would continue updating this thread until it's completion.

Day one I tore out all the old insulation and particle board on the walls and framed out my floor to 8x4. I sprayed foam into every crack I could find...

Day one I tore out all the old insulation and particle board on the walls and framed out my floor to 8x4. I sprayed foam into every crack I could find...