You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

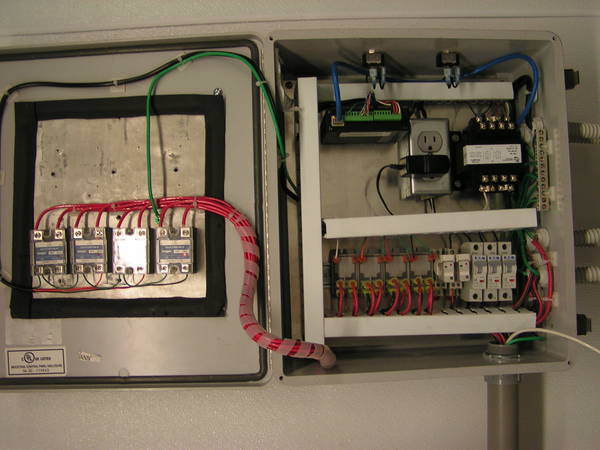

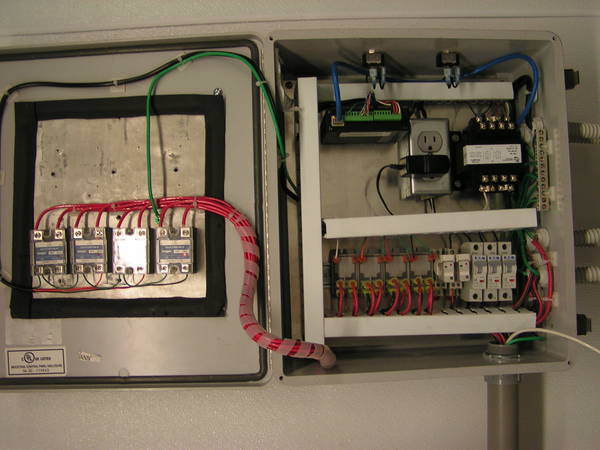

2bbl electric control panel

- Thread starter dolemike

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

How big of a boil are you doing? I have a 60 gallon BK & MT but my HLT is only 20 gallons so I can't actually brew 2 barrels at once but We just did a 32 gallon boil this weekend with 2 - 5500 elements and had plenty of power to do more... I'm not sure if we had enough to do 60 gallons or not but once we got a nice rolling boil I was able to cut the elements down to about 62 % and maintained a nice rolling boil, boiled off 32 gallons down to about 27 gallons with a 60 min boil. I am running the system off of a 60 amp breaker in my panel running a 60 amp GFI panel and had no issues. P-J made up the schematic for me I gave him a description of my system and he put an amazingly easy to follow schematic together I'll attach it. P-J is the man

How big of a boil are you doing? I have a 60 gallon BK & MT but my HLT is only 20 gallons so I can't actually brew 2 barrels at once but We just did a 32 gallon boil this weekend with 2 - 5500 elements and had plenty of power to do more... I'm not sure if we had enough to do 60 gallons or not but once we got a nice rolling boil I was able to cut the elements down to about 62 % and maintained a nice rolling boil, boiled off 32 gallons down to about 27 gallons with a 60 min boil. I am running the system off of a 60 amp breaker in my panel running a 60 amp GFI panel and had no issues. P-J made up the schematic for me I gave him a description of my system and he put an amazingly easy to follow schematic together I'll attach it. P-J is the man

Wow.! Thank you so much for the kudos and the reference.

For dolemike:

Here is a full scale image:

As always, click on the image for a full scale diagram printable on Tabloid paper (11" x 17")

If I can help you with changes to the wiring plan, please let me know.

P-J

I think you will need more than 11,000 watts for a 62 gallon batch (about 70-72 gallon pre boil volume). I brew 35 gallon batches (42 gallon pre-boil volume) with 9000 watts in my BK. I have to run it at 90% power after I reach a boil.

Budzu

Well-Known Member

I think you will need more than 11,000 watts for a 62 gallon batch (about 70-72 gallon pre boil volume). I brew 35 gallon batches (42 gallon pre-boil volume) with 9000 watts in my BK. I have to run it at 90% power after I reach a boil.

Actually 11kw does just fine, I boil 73 gallons with it. 2 5.5kw at 95% power. I get low boil-off, but the boil is fine and quite active.

I wired a control panel for my 2 bbl electric brewery, but used 5 separate gfci's from the main panel. From there is conduit into the brewery to my CP. This turned out much more affordable and allowed me to use only 10 awg max, and avoid any expensive industrial gfci's. I can also run 22,000 watts fully on all at once.

Edit: The 5 gfci's include one 20 amp single pole along with the 4 30 amp gfci's for the heaters.

EarthBound

Well-Known Member

Actually 11kw does just fine, I boil 73 gallons with it. 2 5.5kw at 95% power. I get low boil-off, but the boil is fine and quite active.

I wired a control panel for my 2 bbl electric brewery, but used 5 separate gfci's from the main panel. From there is conduit into the brewery to my CP. This turned out much more affordable and allowed me to use only 10 awg max, and avoid any expensive industrial gfci's. I can also run 22,000 watts fully on all at once.

Edit: The 5 gfci's include one 20 amp single pole along with the 4 30 amp gfci's for the heaters.

Very good idea to separate into several circuits. I'm very interested in your design. Might you have a schematic?

Actually 11kw does just fine, I boil 73 gallons with it. 2 5.5kw at 95% power. I get low boil-off, but the boil is fine and quite active.

I wired a control panel for my 2 bbl electric brewery, but used 5 separate gfci's from the main panel. From there is conduit into the brewery to my CP. This turned out much more affordable and allowed me to use only 10 awg max, and avoid any expensive industrial gfci's. I can also run 22,000 watts fully on all at once.

Edit: The 5 gfci's include one 20 amp single pole along with the 4 30 amp gfci's for the heaters.

What else are you running besides 2 elements in each kettle and maybe a pump or 2? I run 2 elements and maybe 2 pumps a time with no issues on one amp gfi. I suppose I could have brought in another 60 amp gfi if I wanted to run the HLT and MT at the same time but don't really see the need for it. A 60 amp gfi panel at HD is only $72.00. I would think 2 of these would be cheaper than purchasing 5 and allot less wiring IMO

Budzu

Well-Known Member

To use 60a gfi's would require more wiring, more components, not less.

Firstly the bundle of 10awg wires was run through the conduit together and presented no issues.

Second if I ran 2 60amp lines to the control box, I'd need additional circuit protection in the box, on top of all the components in there presently. There would not be room in this box obviously. Plus it would require additional wire sizes run etc. Easier and cheaper to buy one roll of 10 gauge wire.

The fifth gfi is a dedicated 120v circuit, feeds the pump and the 12v transformer/bcs.

Firstly the bundle of 10awg wires was run through the conduit together and presented no issues.

Second if I ran 2 60amp lines to the control box, I'd need additional circuit protection in the box, on top of all the components in there presently. There would not be room in this box obviously. Plus it would require additional wire sizes run etc. Easier and cheaper to buy one roll of 10 gauge wire.

The fifth gfi is a dedicated 120v circuit, feeds the pump and the 12v transformer/bcs.

To use 60a gfi's would require more wiring, more components, not less.

Firstly the bundle of 10awg wires was run through the conduit together and presented no issues.

Second if I ran 2 60amp lines to the control box, I'd need additional circuit protection in the box, on top of all the components in there presently. There would not be room in this box obviously. Plus it would require additional wire sizes run etc. Easier and cheaper to buy one roll of 10 gauge wire.

The fifth gfi is a dedicated 120v circuit, feeds the pump and the 12v transformer/bcs.

Makes sense

TJTHEBEST

Well-Known Member

So with this using multiple circuits idea, would it be possible to use two 20 amp circuits to power one 5500 watt element? Or is there not a way to run them like that?

stumpjmper29er

New Member

Is there more then one 240 circuits? And if so would you happen to know the max continuous amps on the circuit(s)?

As I read that diagram, it's fed by a single 60-amp 240 circuit.Is there more then one 240 circuits? And if so would you happen to know the max continuous amps on the circuit(s)?

That is absolutely correct.Is there more then one 240 circuits? And if so would you happen to know the max continuous amps on the circuit(s)?

As I read that diagram, it's fed by a single 60-amp 240 circuit.

Also, there are circuit breakers in place to protect the various devices. The max amp draw is the acculimated total of the devices being used. Keep in mind that switch #6 allows either the HLT - Or - BOIL elements to be powered.

P-J

stumpjmper29er

New Member

That is absolutely correct.

Also, there are circuit breakers in place to protect the various devices. The max amp draw is the acculimated total of the devices being used. Keep in mind that switch #6 allows either the HLT - Or - BOIL elements to be powered.

P-J

Heavy stuff. Thanks guys!

kal

Well-Known Member

So with this using multiple circuits idea, would it be possible to use two 20 amp circuits to power one 5500 watt element? Or is there not a way to run them like that?

No. That 5500W element will draw ~23 amps of current continously when used. You can't piggy back current. To get 5500W of power out of two 20A circuits you'd need to use two heating elements that totalled 5500W, and neither should draw more than 16-20A.

To the OP: I've seen a lot of 2 bbl brewers use my 50A control panel design and as someone else mentioned, 11Kw is plenty for a rolling boil at the 2 bbl size.

Good luck!

Kal

jeffmeh

Well-Known Member

- Joined

- Feb 26, 2009

- Messages

- 2,145

- Reaction score

- 216

Just to confuse matters, another approach would be to wire the switches and contactors to the heating elements to achieve 4 states:

1) All off

2) Both on in the BK, both off in the HLT

3) Both off in the BK, both on in the HLT

4) One on and one off in the BK, one on and one off in the HLT

1) All off

2) Both on in the BK, both off in the HLT

3) Both off in the BK, both on in the HLT

4) One on and one off in the BK, one on and one off in the HLT

Just to confuse matters, another approach would be to wire the switches and contactors to the heating elements to achieve 4 states:

1) All off

2) Both on in the BK, both off in the HLT

3) Both off in the BK, both on in the HLT

4) One on and one off in the BK, one on and one off in the HLT

That's what I've done. one 4500W & one 5500W in each vessel. Used relays to interlock them so that you cannot power more then 2 elements at once (one 4500W and one 5500W). Fed by 50A, currently only 15G setup, but i wanted speed (and eventually plan to upsize my kettles)

I am surprised that 11,000 watts will boil a 2 barrel batch. I use 9000 watts for a 1 barrel batch and run my PID on 90% power during the boil. My BK is uninsulated - perhaps that makes the difference. Regardless, I would think it would take a long time to reach a boil. By my calculations it would take about an hour to go from 150 to 210F with a 2 barrel batch.

I can't get a full 2 barrel batch my Bk is only 58 gallons but we have boiled 50 gallons with no issues. I start heating the Bk as soon as the elements are covered once the sparge is complete it only took another 10 - 15 minutes to reach a nice rolling boil.

Similar threads

- Replies

- 10

- Views

- 668

- Replies

- 2

- Views

- 669

- Replies

- 4

- Views

- 552