Hey all, Long time lurker, new member here!

I've used this site since I started brewing for recipes, and now it's time I got involved.

At first glance, I thought this would be a simple plug-n-play system. Boy was I wrong!

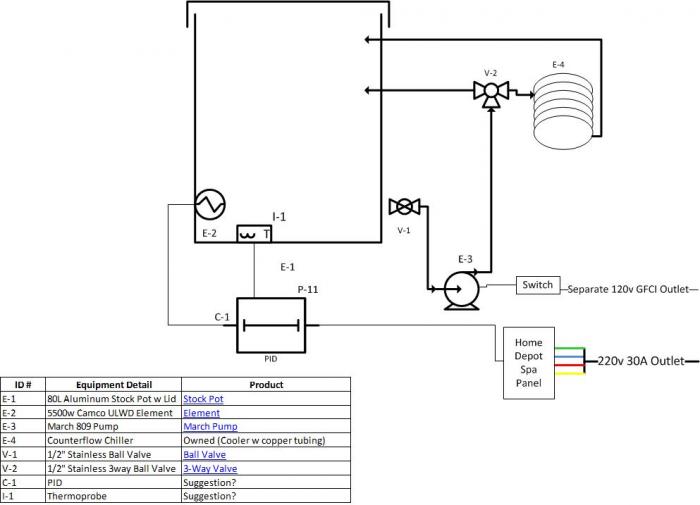

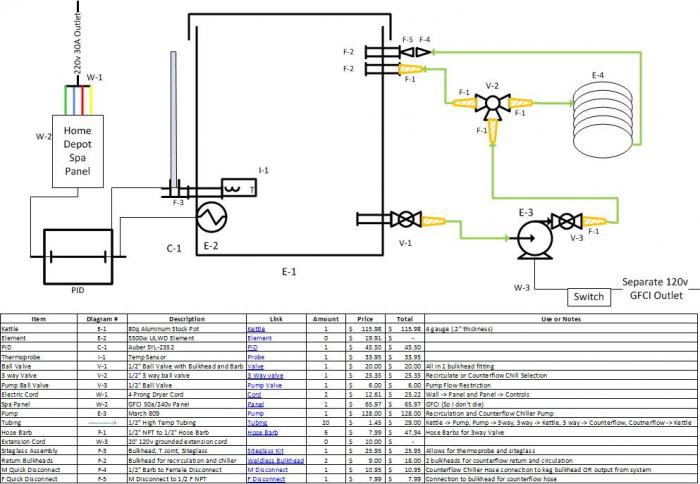

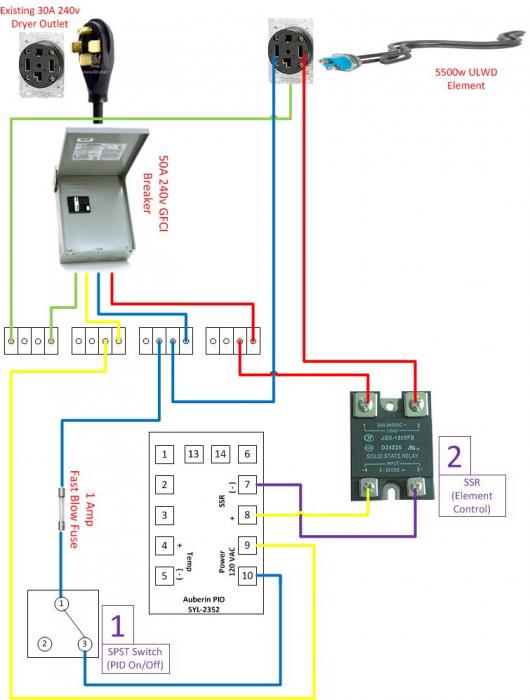

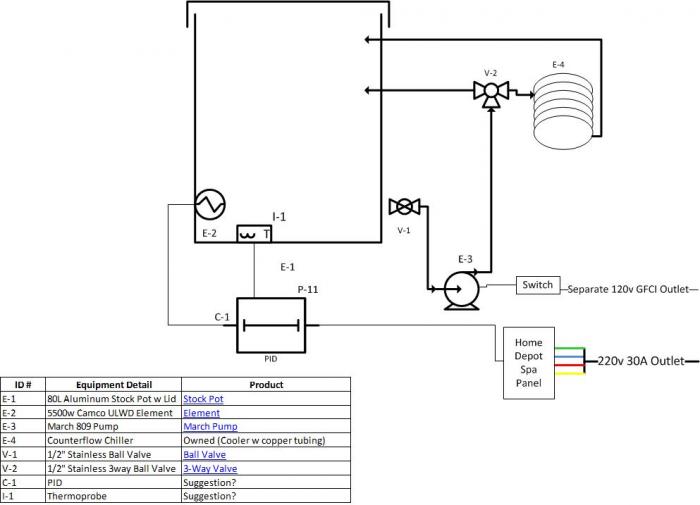

I'm going to be building a basic 1 kettle (80q aluminum) e-BIAB system using an existing 220v 30A dryer outlet. I've attached a very basic representation of the system. I'll use a PID to monitor mash temps, and a march pump for recirculation and counterflow chilling.

Please take a look and make any suggestions! I don't want the full automation, but I can't seem to find any way around the PID either. I'll need advice on what PID to use, and what thermoprobe works with it.

I'll be checking back on this all the time, so please leave any questions or comments. I'll need a wiring diagram in the future, but please don't make anything for me as of now. I want to make sure this is the right setup before any of you go out of your way for me *cough* PJ *cough*. :cross:

You guys have done awesome work, and I'm really looking forward to this build.

Thanks in advance, and happy brewing!

`Sickles

I've used this site since I started brewing for recipes, and now it's time I got involved.

At first glance, I thought this would be a simple plug-n-play system. Boy was I wrong!

I'm going to be building a basic 1 kettle (80q aluminum) e-BIAB system using an existing 220v 30A dryer outlet. I've attached a very basic representation of the system. I'll use a PID to monitor mash temps, and a march pump for recirculation and counterflow chilling.

Please take a look and make any suggestions! I don't want the full automation, but I can't seem to find any way around the PID either. I'll need advice on what PID to use, and what thermoprobe works with it.

I'll be checking back on this all the time, so please leave any questions or comments. I'll need a wiring diagram in the future, but please don't make anything for me as of now. I want to make sure this is the right setup before any of you go out of your way for me *cough* PJ *cough*. :cross:

You guys have done awesome work, and I'm really looking forward to this build.

Thanks in advance, and happy brewing!

`Sickles