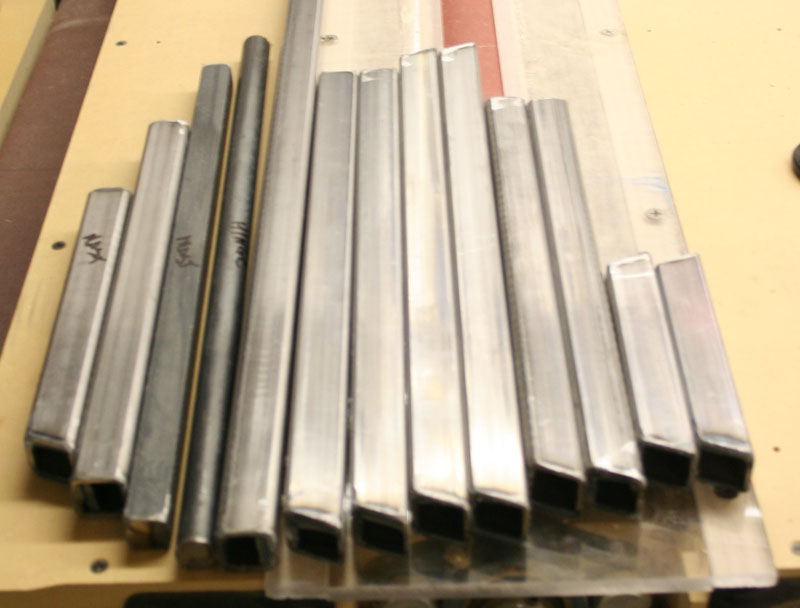

The crane is essentially done.. All welded up, sanded and ready to paint...

I am planning on drilling and tapping for the rubber feet tomorrow morning, cleaning the whole thing off with acetone, and than spraying with truck bed liner..

Since it is an acetone based product, after I let the first coat dry thoroughly, I can cut some runners for the keggle to sit on from textured 1/8" ABS, and then spray a second coat of truck bed liner on the keggle support and then stick the ABS on the rails while the spray liner is still wet, and that should create a permanent bond, as the acetone in the truck bed liner will melt the ABS, and then the ABS should bond to the truck bed liner as if they are one....

That's the plan anyways.. If for some reason that doesn't work, I guess I'll use some RTV to attach the ABS....

Other than that, I need to drill and tap a bolt hole on the end of the hinge shaft so a keeper washer and screw will make the mast and boom hinge stay together as one piece...

I've got a couple of keeper pins coming (should be here today), that will allow the whole stand and crane to break down into four pieces for storage when the pins are removed....

I'm also going to pick up some cam lock fittings this week, as I want something more robust and safe than the Garden Hose Quick Disconnects I am currently using.. Plus the lower profile of the cam locks will allow me to build the second tile topped cart, and have them slide together when not in use, to hide all the plumbing and give me plenty of space to store the entire brewery and related equipment underneath when not in use... Turning my brew stands into a tiled 8' long counter for general use on the porch when not brewing...

So now, onto deciding what I want to do about the grain basket and COFI tube and all that..

Other than that, I gotta clean out the fermentation chamber, and move it to the patio (I decided that it would be better there, and I'll deal with heating it during fermentation this winter when I get there, as the current 60w light bulb I am using now probably ain't gonna cut it when the temps drop into the teens)..

Ordering some 1/2" ID braided clear vinyl/PVC hose this week end for transferring from brewery to fermenter....

Then I'm ready to try it all out... Unless I decide to go ahead and order the plastic conical and do that first, which is a definite possibility...