- Joined

- Nov 26, 2013

- Messages

- 7,611

- Reaction score

- 14,409

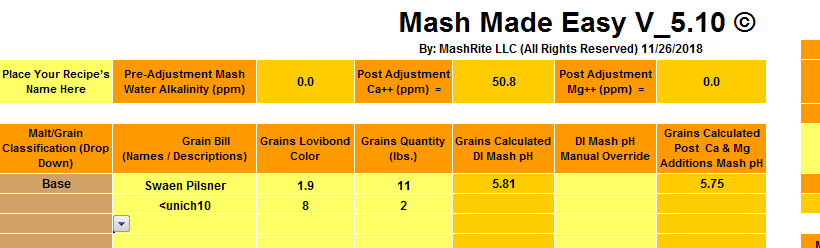

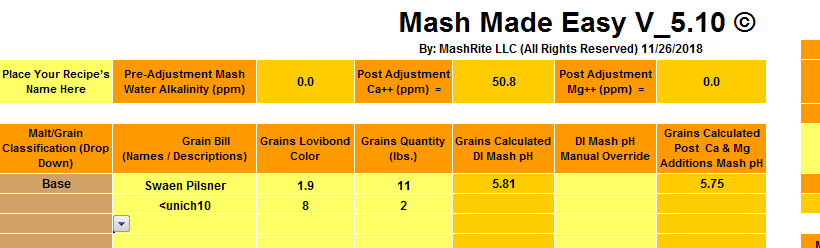

Opened 5.1 in Excel 2007, no FALSEs

Added a line (and misspelled Munich)

Deleted the leftmost col. Still no FALSE.

Edit: same thing in Excel 2016. No FALSEs. (Falsies?)

Added a line (and misspelled Munich)

Deleted the leftmost col. Still no FALSE.

Edit: same thing in Excel 2016. No FALSEs. (Falsies?)