mhermetz

Well-Known Member

So now that I have my AG setup working nicely I'm already setting my sights on the next project.

I always said I'd never go 10gallon batches but some of my beers just can't stay around long enough with my friends. With going 10g this would essentially make my 5 gallon AG setup obsolete. So here's my idea:

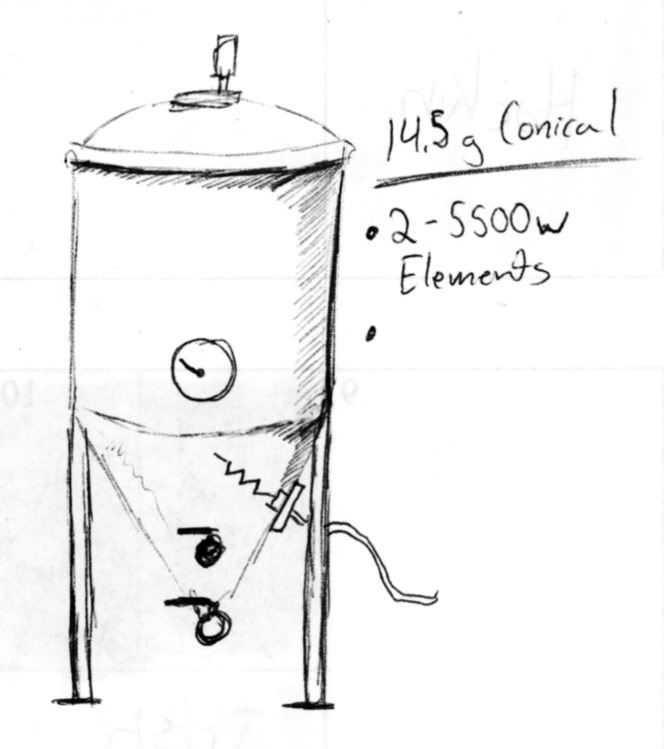

I based this off the Blingman 14.5 conical, but if anyone else knows of cheaper Conicals let me know. Basically it's going to serve as my HLT, BK and Fermenter.

Once boiling is done I'll use a Immersion chiller to bring the tempature down. This will require me to build a new and much larger one too. I suppose I could also look into this no-chill method.

Here's my cost estimate:

Blichmann Conical 14.5 g.......................................... $799

2 -5500w Elements ................................................ $120

.5" of copper pipe.................................................. $95

Welding cost ........................................................ $250

Total: $1265

What you guys think, will this work?

I always said I'd never go 10gallon batches but some of my beers just can't stay around long enough with my friends. With going 10g this would essentially make my 5 gallon AG setup obsolete. So here's my idea:

I based this off the Blingman 14.5 conical, but if anyone else knows of cheaper Conicals let me know. Basically it's going to serve as my HLT, BK and Fermenter.

Once boiling is done I'll use a Immersion chiller to bring the tempature down. This will require me to build a new and much larger one too. I suppose I could also look into this no-chill method.

Here's my cost estimate:

Blichmann Conical 14.5 g.......................................... $799

2 -5500w Elements ................................................ $120

.5" of copper pipe.................................................. $95

Welding cost ........................................................ $250

Total: $1265

What you guys think, will this work?