SantaClaus

Well-Known Member

Hey all I have a couple questions regarding strike water and mashing volumes. I think I'm on the right path here, but missed my OG yesterday and am hoping the wise-folks here can help me out.

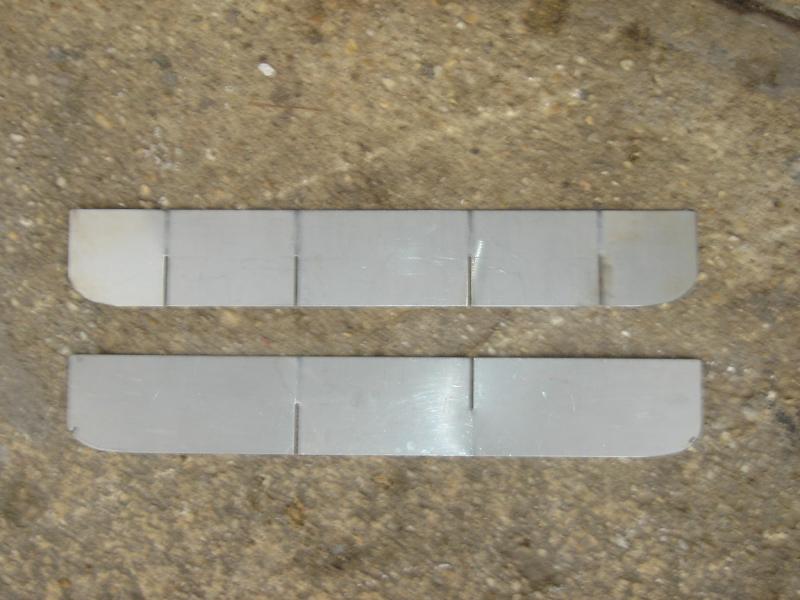

So here's the deal, I'm using a sanke keg with a PICO style false bottom for my MLT - http://www.homebrewing.org/Stainless-Steel-PICO-style-keg-kettle-false-bottom_p_1010.html

With this I have 3gallons of space under the false bottom. I do, however, have a dip tube under the false bottom that sucks up all but a quart of water. To equate for this empty space I add 3 additional gallons of stike water to my mash, to bring the water level up to the false bottom.

For example if I'm mashing 15lbs of grain w/ 1.5quarts per lb

(15 x 1.5 = 22.5quarts or 5.6 gallons) I'll add a total of 8.6 gallons of strike water; 3 to fill the dead space and 5.6 to mash the grain.

At the conclusion of my mash, I'll fire up the burner (modest flame) and slowly recirculate from the bottom to the top of the grain bed until the mash bed has reached 168 - takes about 15mins.

From there I'll begin transferring wort into the brew kettle, while slowly fly-sparging the grain w/ 175degree water. I'll build up about 1.5 -2" of water on top of my grain bed, while draining wort off at the same rate water is being added. This takes about 45min - 1 hr to achieve the 6.5-7.0 gallons of wort for my boil.

Yesterday I brewed a Belgian dubbel which BeerSmith calculated having a 1.070 pre-boil gravity w/ 1.090 final. I was a bit shy of that 1.052 per-boil, 1.072 post.

Anyone have any ideas?

- is it that extra 3 gallons of water? - should I do away with that?

Could I batch sparge with this dead space, and if so how?

Thanks in advance for the help

So here's the deal, I'm using a sanke keg with a PICO style false bottom for my MLT - http://www.homebrewing.org/Stainless-Steel-PICO-style-keg-kettle-false-bottom_p_1010.html

With this I have 3gallons of space under the false bottom. I do, however, have a dip tube under the false bottom that sucks up all but a quart of water. To equate for this empty space I add 3 additional gallons of stike water to my mash, to bring the water level up to the false bottom.

For example if I'm mashing 15lbs of grain w/ 1.5quarts per lb

(15 x 1.5 = 22.5quarts or 5.6 gallons) I'll add a total of 8.6 gallons of strike water; 3 to fill the dead space and 5.6 to mash the grain.

At the conclusion of my mash, I'll fire up the burner (modest flame) and slowly recirculate from the bottom to the top of the grain bed until the mash bed has reached 168 - takes about 15mins.

From there I'll begin transferring wort into the brew kettle, while slowly fly-sparging the grain w/ 175degree water. I'll build up about 1.5 -2" of water on top of my grain bed, while draining wort off at the same rate water is being added. This takes about 45min - 1 hr to achieve the 6.5-7.0 gallons of wort for my boil.

Yesterday I brewed a Belgian dubbel which BeerSmith calculated having a 1.070 pre-boil gravity w/ 1.090 final. I was a bit shy of that 1.052 per-boil, 1.072 post.

Anyone have any ideas?

- is it that extra 3 gallons of water? - should I do away with that?

Could I batch sparge with this dead space, and if so how?

Thanks in advance for the help