When you guys said, unwashed yeast should be used within * days or max * weeks I was always wondering, then what about harvesting yeast from commercially obtained beer? Unwashed yeast had been sitting there under pretty much stress, plus CO2 pressure, uncertain temperature and all that.

So I saved some unwashed US-05 yeast from my brew kegged on 25th Oct (150 ml of beer just as it came from the fermenter, left for a day with loose cover to off-gas, then tightened and refrigerated) and plated it on 30th Dec.

Under microscope it was all death and devastation. Maybe one live cell to a few hundred dead; no budding cells. Altogether looking at it was sorta depressive.

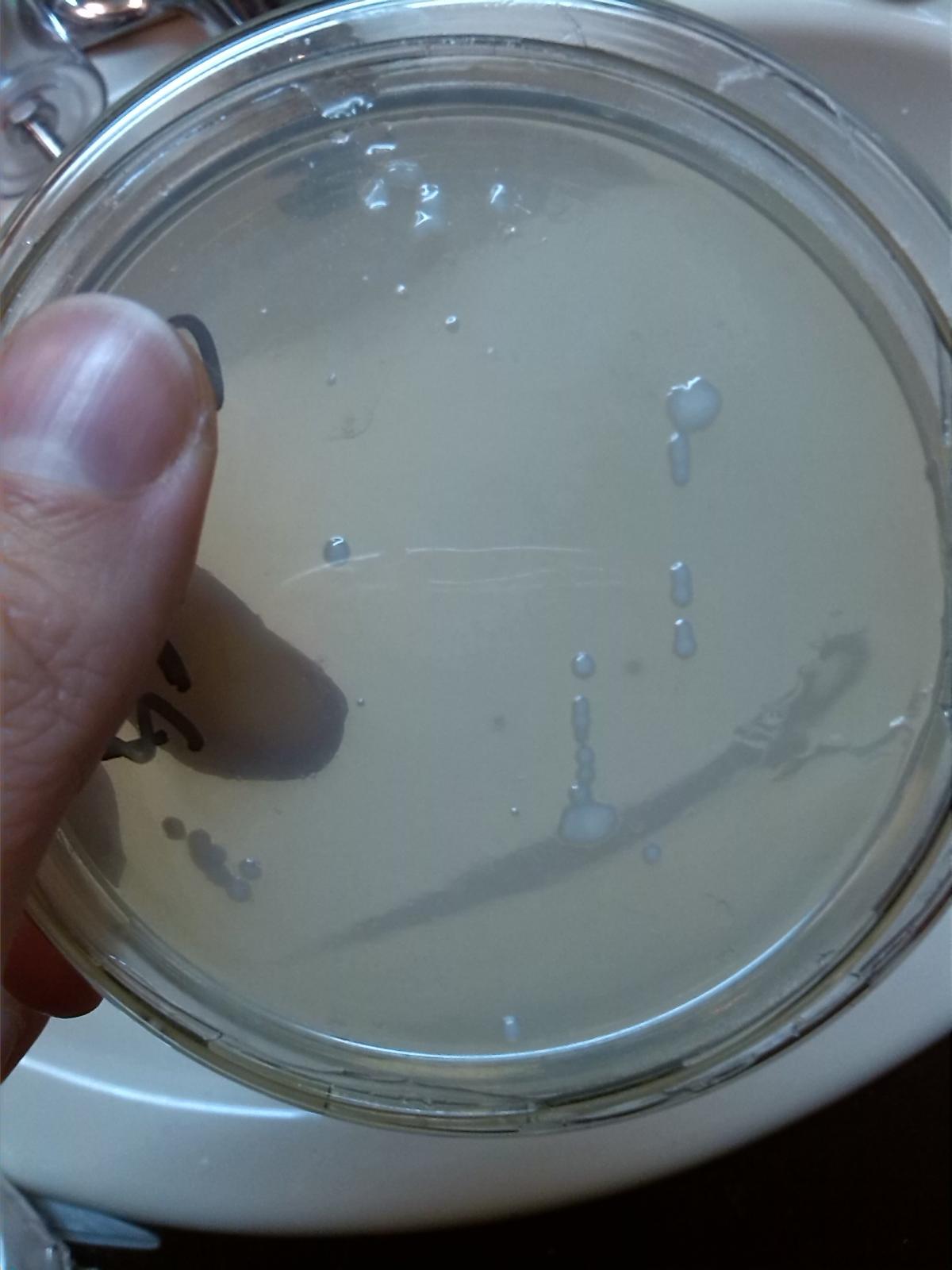

I stuck it into incubator for about 80+ hours at 25C.

By now there are 3 plates:

one with no growth at all - this was taken from liquid fraction;

one with some massive but ugly discolored growth - taken from the cake;

and one with some reasonable growth - taken after shaking up the jar and letting it sit for a few minutes.

I'm not really willing to try to brew my next batch on this yeast as there is still risk that it has been too stressed or has high percent of mutations, or whatever.

But is there a less risky way to check whether this yeast is still workable?

I have fresh liquid yeast at hand so I'm not desperate for yeast, just want to know it just in case. I feel too lazy to set up a mini-batch but if I could try on a pint of unhopped 1040 DME I probably would go ahead. Do you think this way would be able to prove any point?

Thanks!