I have a 2 loop 120v brewery setup. It works beautifully up to a 5.5 gallon final volume batch and I've boiled up to 11 gallons in it without too much trouble (though never brewed that big).

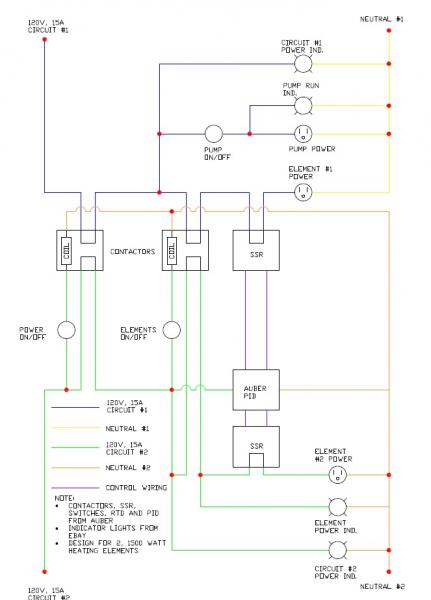

Basic schematic is thus:

Powered from two separate 120v loops.

Loop 1: PID-master switch-single PID controlled plug for element

Loop 2: a pair of switch controlled outlets, one for the second boil kettle element, one for the pump.

I have a stainless rims tube with a 1500w water heater element in it that is used in the mash, and the kettle is a keg fitted with a pair of 1500 or 1600w elements (I dont remember which)

Brew day looks like this:

Fill Mash tun (cooler with false bottom and CPVC sparge manifold) to 3.5 gallons. Begin recirculating through the rims tube, set rims tube to desired strike temp, allow to heat (~20-30 minutes). As the strike is heating, I fill the kettle with required sparge volume (using formula total preboil volume less [3.5-.125*lbs grain]) and fire one of the kettle elements to heat sparge water.

Shut off pump, dough in, replace lid and restart circulation. When temp has stabilized flip the PID switch so the rims element begins firing to maintain mash temp, allow to mash (usually 1 hour)

Ramp temp in 5 degree increments until ~175 (~30 minutes) and drain first runnings to a 4 gallon stainless pot.

Recirculate heated mash water from kettle, through grain bed, back to kettle (30 minutes to an hour depending on how efficiency fixated I am). I start with a slow flow and leave the valve closed so as to avoid disturbing the grain bed, increase flow and allow running into the kettle after I get ~ a half inch of liquid above the grain bed.

After sparge recirculation, I pour the first runnings into the kettle and swap the rims element plug in for the second kettle element and run it in manual mode, usually ~90% for a 5.5 gallon batch. Bring to boil (~30 minutes)

Boil. (1 hour)

Chill via counterflow chiller, first recirc to sterilize, then recirc until temp is adequately dropped (~40 minutes)

pump to carboy

pitch yeast.

Worst case scenario, looking at a 5.5 hour brewday, but if I'm really on it and the beer is small I can be done in 4 and a half easily.

If you PM me your email I'll try and put together a parts list spreadsheet and such, if this sounds like the kind of rig you are looking for.