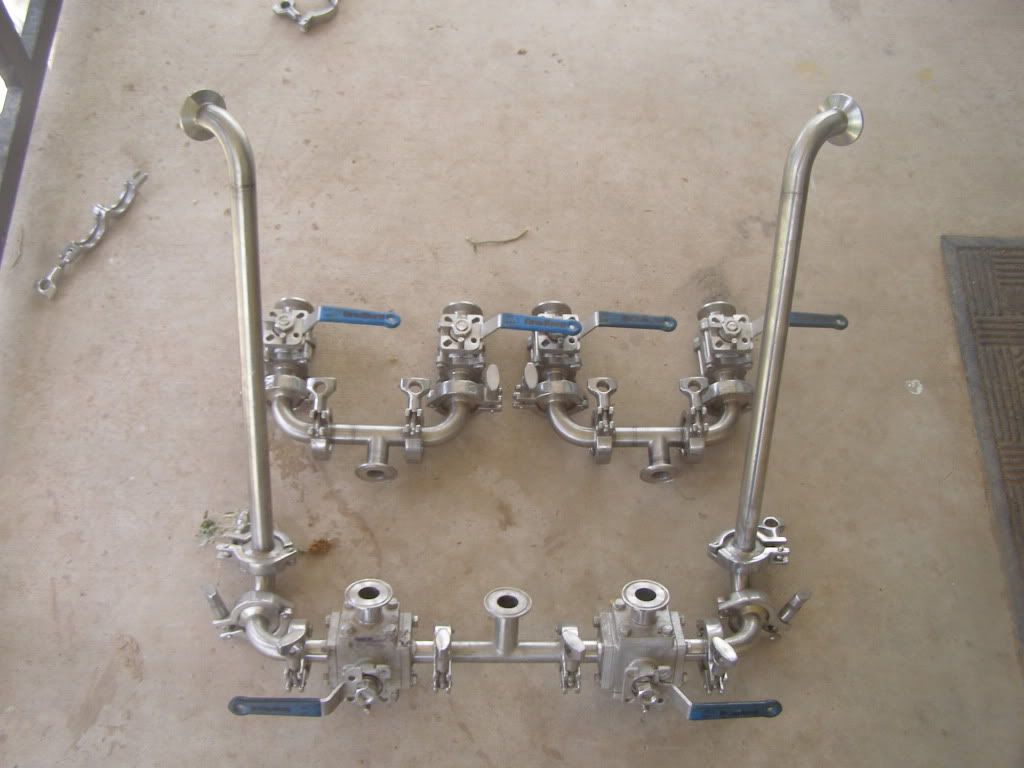

I have found my hobby! my favorite thing to do on the weekend is build stuff and better yet build stuff and drink beer so what better than brewin i am so excited to build this brewery i cant even contain myself. I have never brewed all grain and have only brewed half a dozen extract brews under my belt my last brew was so hectic i resolved to build a brewstand to help organize the madness. my previous stand was a few 8x8 timbers below my turkey fryer it was unstable and a pain in my a$$. i had an improvised keggle w/out valve and a poorly built wort chiller. i was on my own doing what i could, then i found home brew talk i have read every thread on this site, a plethora of information many sleepless nights and doodling and here's what i came up with if you see anything that could use improvement speak up i need all the help i can get!!!! i just picked up my valves and a bunch of fittings and have a meeting with the welder tomorrow. i built the stand a few weeks ago and NEED to get all the good stuff on asap so at least i can brew extract i plan on two pumps and hard lining everything, sight glasses the works!!! if any thing is worth doing right its a brewery,without further a due here it is!