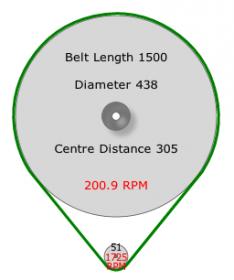

So, you want to reduce the speed to 175-200 or so RPM for milling.

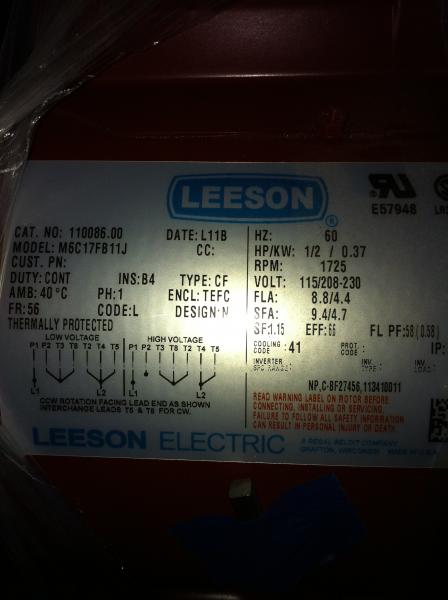

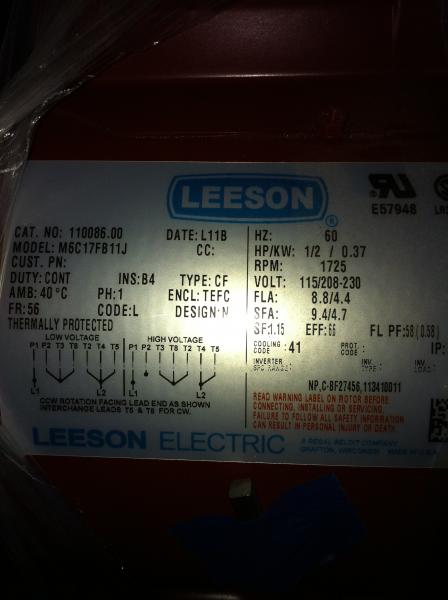

Source (motor) - 1725

Desired (mill) - 200

1725 / 200 = 8.625

so, a ration of 8.625:1

If you use a 2" diameter v-belt sheave on your motor (pretty common), you will need one 8.625 times larger, or 17.25" diameter on your mill drive shaft.

Then, figure out how long of a belt you need to make this work, guessing 40-60 inches would do the trick. 60" belt would be 12" gap from center of your motor shaft to center of your mill shaft.

Hope this helps! Good luck!