aubiecat

Well-Known Member

Got about everything I need to get a two carboy fermentation cabinet up and running. I noticed Sears had their 7.2 qu ft chest freezer on sale for $195.00 but they didn't have any in the small store here. So I printed the page from their website and took it to Home Depot. HD price matched their 7.0 qu ft model for me. :rockin:

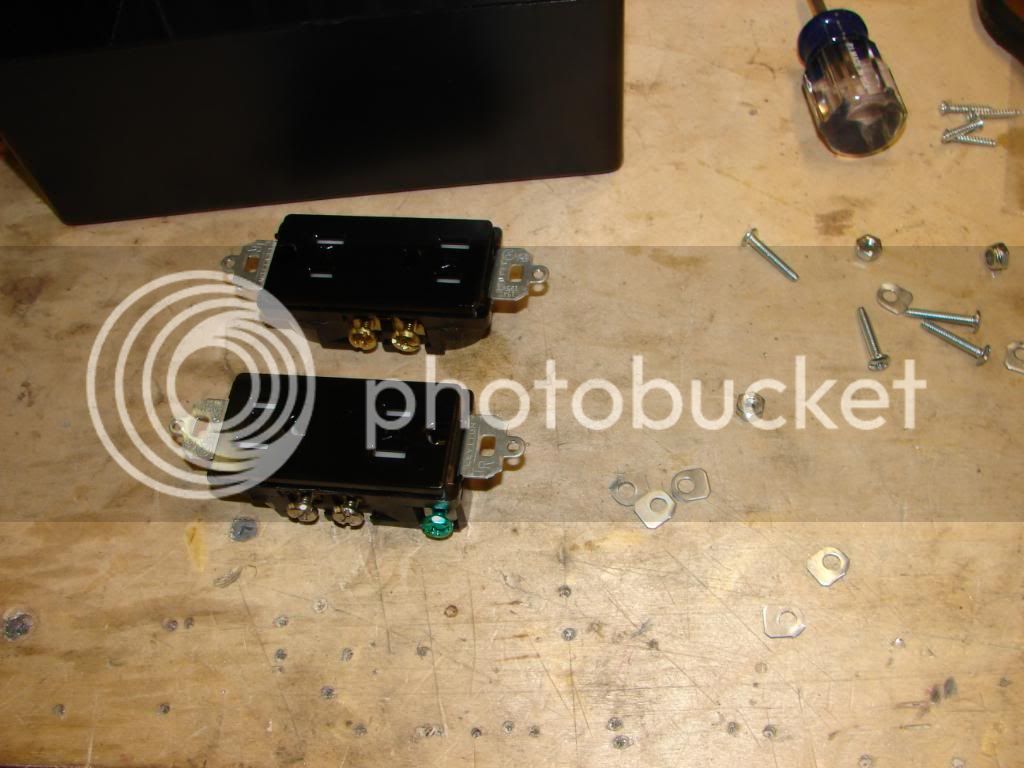

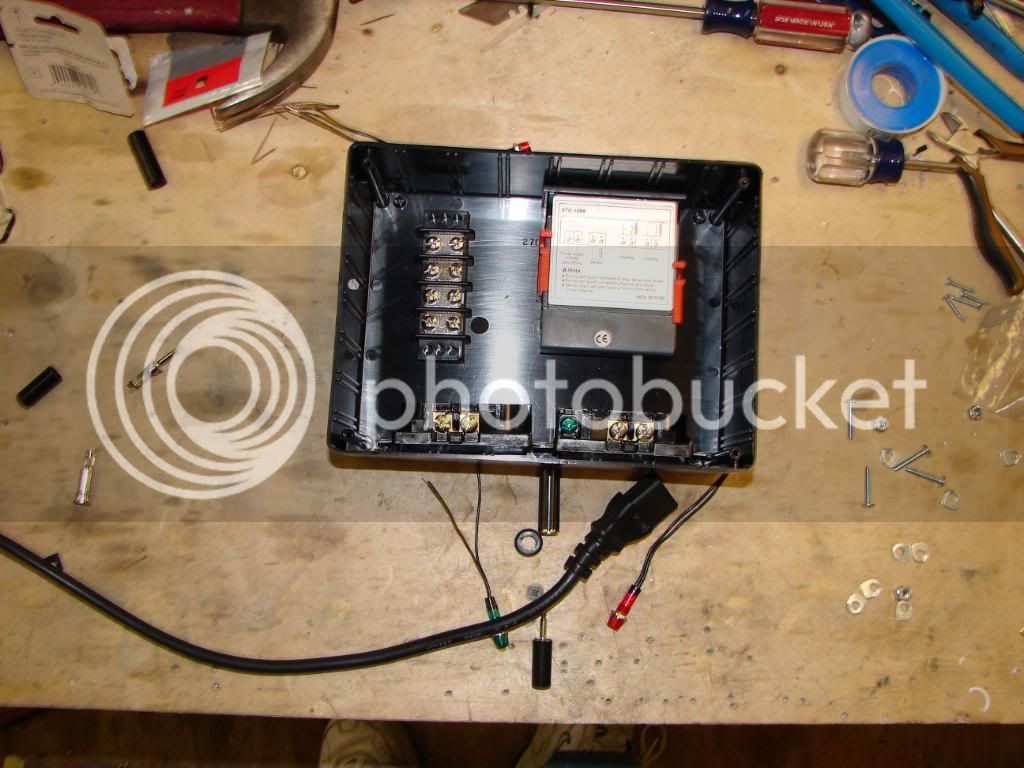

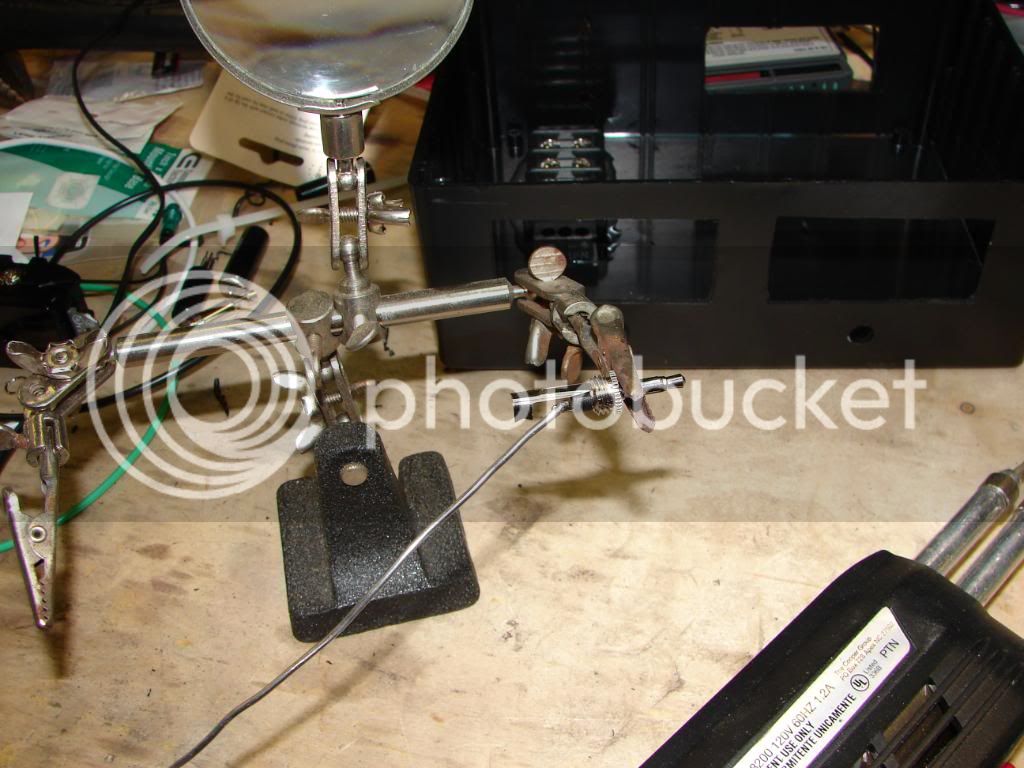

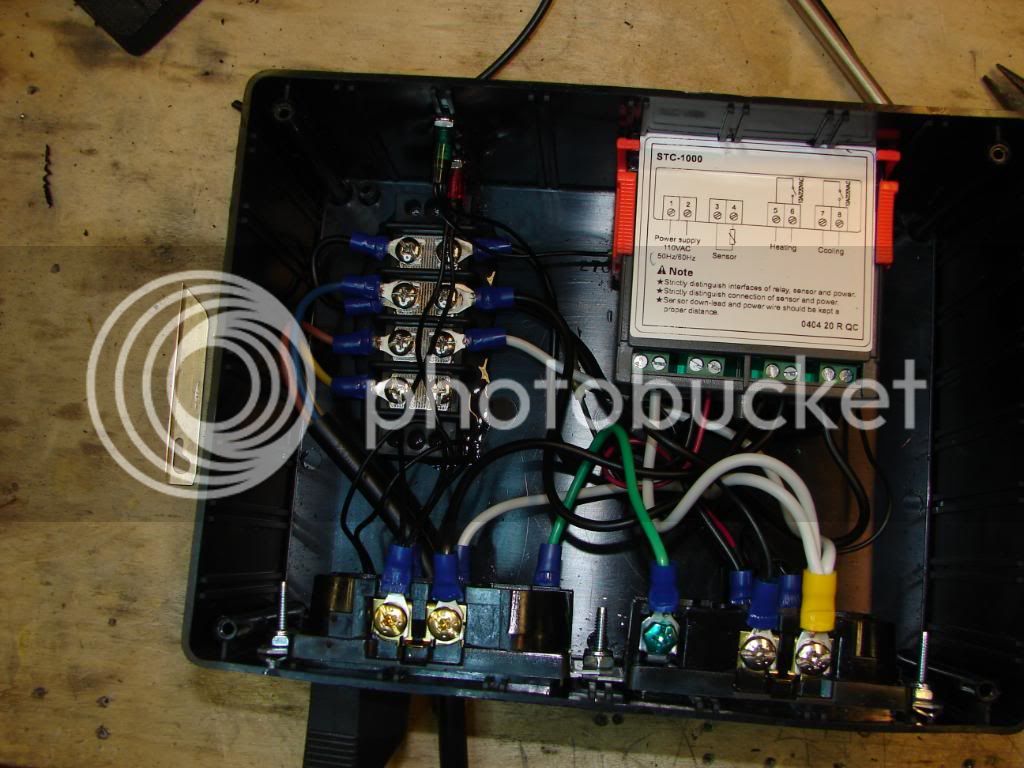

I want to make a separate control box instead of mounting the controller into the freezer should I decide to do something else with the freezer in the future. Heck it could end up being a keezer some day, who knows.

I still need a project box and a 1/8" plug to complete the control box. Don't know if I will need a fan in there but I have 1 or 2 laying around.

Checking the possible fit of two 6.5 gallon carboys, I only have one right now. It will be tight but they will fit.

Using a pen as a marker, there will be just enough room. Whew!

The baskets should come in handy for something.

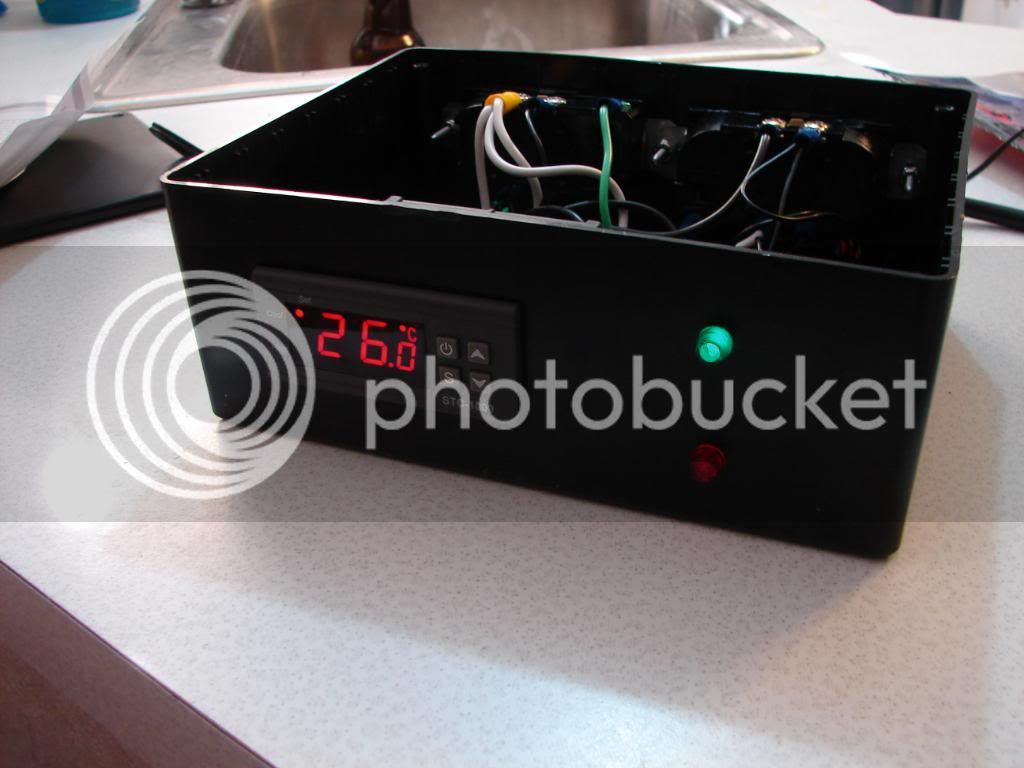

I want to make a separate control box instead of mounting the controller into the freezer should I decide to do something else with the freezer in the future. Heck it could end up being a keezer some day, who knows.

I still need a project box and a 1/8" plug to complete the control box. Don't know if I will need a fan in there but I have 1 or 2 laying around.

Checking the possible fit of two 6.5 gallon carboys, I only have one right now. It will be tight but they will fit.

Using a pen as a marker, there will be just enough room. Whew!

The baskets should come in handy for something.