Hey Folks,

Just wanted to post a few pics. Thanks to all the regulars for all the great posts. I dont think I would of had the courage to do anything like this from scratch

4 brews into this and my beer quality has definitely increased.

The small green control panel is on a seperate 120v GFCI circuit. The blue toolbox houses the 240V (contactors/ssrs). The 120V also powers the pump. Reason for this route was the fact that the GFCI cable i picked up ($30) was only 3 wire 240V (2 hot + gnd), vs 4 wire 2 hot, neut and ground. So incorporating a 120v circuit seemed like the easiest solution.

specs:

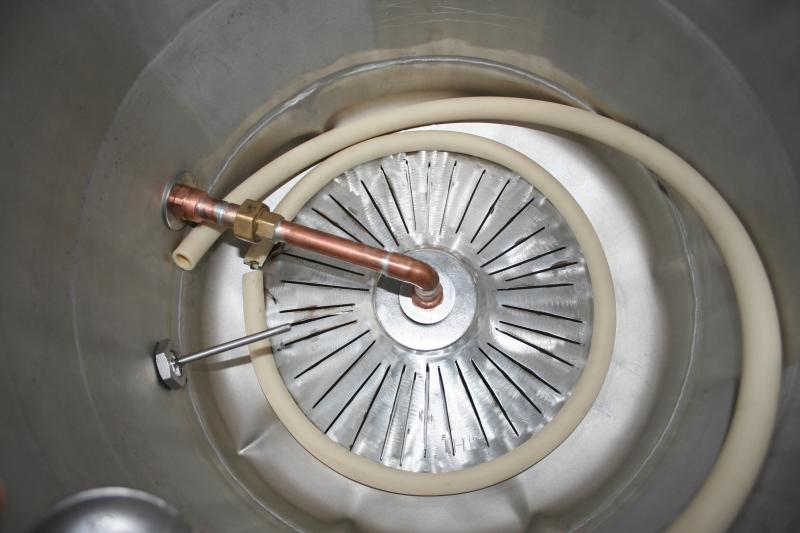

3 13gal kegs

2x 5500 watt heating elements. 30A GFCI 240V service

PID controller w/ RTD probe in HLT

march 809 pump

mlt used to have a rubber top, removed that. very easy to take clean.

still to come is the ventilation system. picked up a hydroponics 400 cfm, will just be making a hood over the BK, and the exterior wall is a few feet away so should be easy peasy. Still looking for a good deal on a stainless table and go single tier w/ 2 pumps, till then the wood will do.

Just wanted to post a few pics. Thanks to all the regulars for all the great posts. I dont think I would of had the courage to do anything like this from scratch

4 brews into this and my beer quality has definitely increased.

The small green control panel is on a seperate 120v GFCI circuit. The blue toolbox houses the 240V (contactors/ssrs). The 120V also powers the pump. Reason for this route was the fact that the GFCI cable i picked up ($30) was only 3 wire 240V (2 hot + gnd), vs 4 wire 2 hot, neut and ground. So incorporating a 120v circuit seemed like the easiest solution.

specs:

3 13gal kegs

2x 5500 watt heating elements. 30A GFCI 240V service

PID controller w/ RTD probe in HLT

march 809 pump

mlt used to have a rubber top, removed that. very easy to take clean.

still to come is the ventilation system. picked up a hydroponics 400 cfm, will just be making a hood over the BK, and the exterior wall is a few feet away so should be easy peasy. Still looking for a good deal on a stainless table and go single tier w/ 2 pumps, till then the wood will do.