shortyjacobs

Well-Known Member

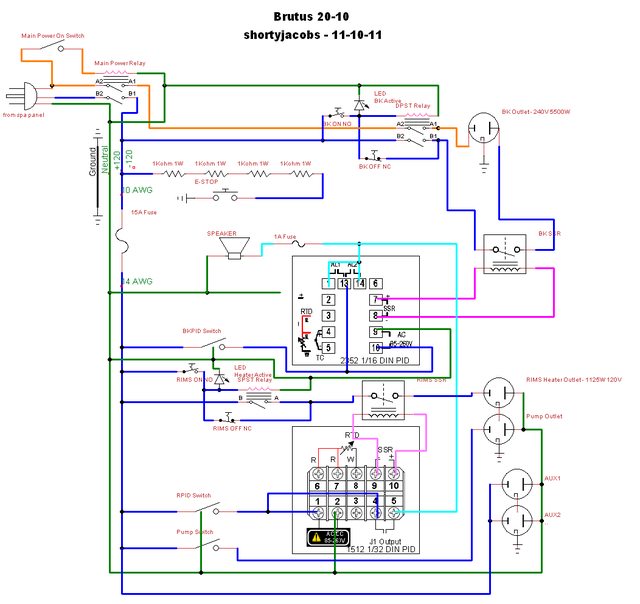

Here's my plan for my electric upgrade. Please give me any and all feedback. The system will be a 10 gallon model of jKarps's Countertop Brutus 20, sort of, with the addition of a RIMS tube. 1 BK/HLT (15 gal keggle), 1 MLT (15 gal cooler), 1 pump.

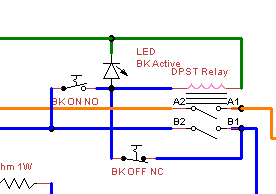

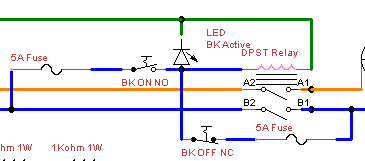

The thing I'm most proud of is the On/Off circuit for the RIMS and BK elements. Push the "on" momentary NO switch to activate the relay circuit and the elements go live. Push the "off" momentary NC switch to deactivate the relay circuit and the elements. When power is cut, the relays open automatically, so the design "fails safe", and also "starts safe", since there's no way the relays can be left on when power is cut, then run dry when power is restored. I thought this was a real novel design, until I realized all red pushbutton momentary switches were NC, and all green ones were NO. Obviously I wasn't the first with this idea. Here's the switches from AD: Red, Green.

Here's the design - click to embiggen: EDIT: Newest Diagram now in Post 14!

Thoughts? Suggestions?

(oh, diagram was made in something called TinyCAD. It's my favorite so far for wiring diagrams - super easy to use, not so much of a huge emphasis on PCB diagrams like so many wiring programs)

The thing I'm most proud of is the On/Off circuit for the RIMS and BK elements. Push the "on" momentary NO switch to activate the relay circuit and the elements go live. Push the "off" momentary NC switch to deactivate the relay circuit and the elements. When power is cut, the relays open automatically, so the design "fails safe", and also "starts safe", since there's no way the relays can be left on when power is cut, then run dry when power is restored. I thought this was a real novel design, until I realized all red pushbutton momentary switches were NC, and all green ones were NO. Obviously I wasn't the first with this idea. Here's the switches from AD: Red, Green.

Here's the design - click to embiggen: EDIT: Newest Diagram now in Post 14!

Thoughts? Suggestions?

(oh, diagram was made in something called TinyCAD. It's my favorite so far for wiring diagrams - super easy to use, not so much of a huge emphasis on PCB diagrams like so many wiring programs)