After doing my most recent all-grain batch and getting low efficiency - https://www.homebrewtalk.com/f36/low-efficiency-brew-day-question-383643/

I decided to do an experiment with milling grain (I have a Barley Crusher) at a few different settings, mashing for one hour, sparging and then taking a gravity reading.

My process was:

#1 Mill grains (I milled all three batches at the beginning)

#2 Place crushed grains into paint strainer bag in 6 quart pot.

#3 Heat up strike water to 167

#4 Add strike water to pot with grains, maintain temp ~152 degrees for 60 minutes, stirring every 10 minutes.

#5 Pull bag out and let excess wort drain back into pot.

#6 Heat up sparge water to 180 (so it was ready in time)

#7 Once the mash has drained from the bag (under five minutes), put the bag in another pot and add the sparge water. Stir

#8 Let sparge pot sit for 5 minutes

#9 Drain as I did in Step #5

#10 Add sparge pot wort to mash pot wort to make 1 gallon

#11 Chill in ice-water bath to 100 degrees

#12 Take hydro reading.

2 lbs of 2 row mashed for 60 minutes and then sparged with enough water to make 1 gallon (2.5 quarts) at 100% efficiency would be 1.072

The number in parentheses is what I got when changing the Efficiency % to match what I got on the gravity reading.

My findings:

.035" yielded 1.044 - adjusted for temp to 1.048 (66% efficiency)

.032" yielded 1.049 - adjusted for temp to 1.053 (73% efficiency)

.030" yielded 1.051 - adjusted for temp to 1.055 (75% efficiency)

(Since I took the hydro readings at 100 degrees I used http://www.brewersfriend.com/hydrometer-temp/ to adjust hydro readings for temp)

Should I have taken the hydro reading just from the mash instead?

Of course the downfalls of this experiment are that:

#1 This was mash efficiency and not brewhouse efficiency

#2 As I did this on the stovetop with smaller pots it is not representative of what my system will get - concerning issues of if the crush is too fine there being a stuck sparge.

Some pictures of the process -

The grain crushed with the mill set at .035"

And here the .032" grain

And now the .030" grain

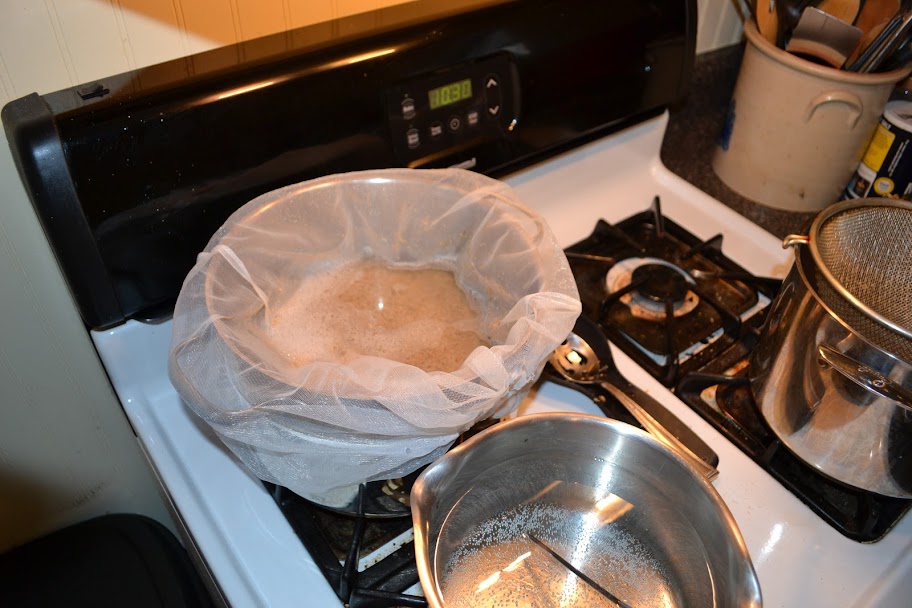

My mash setup

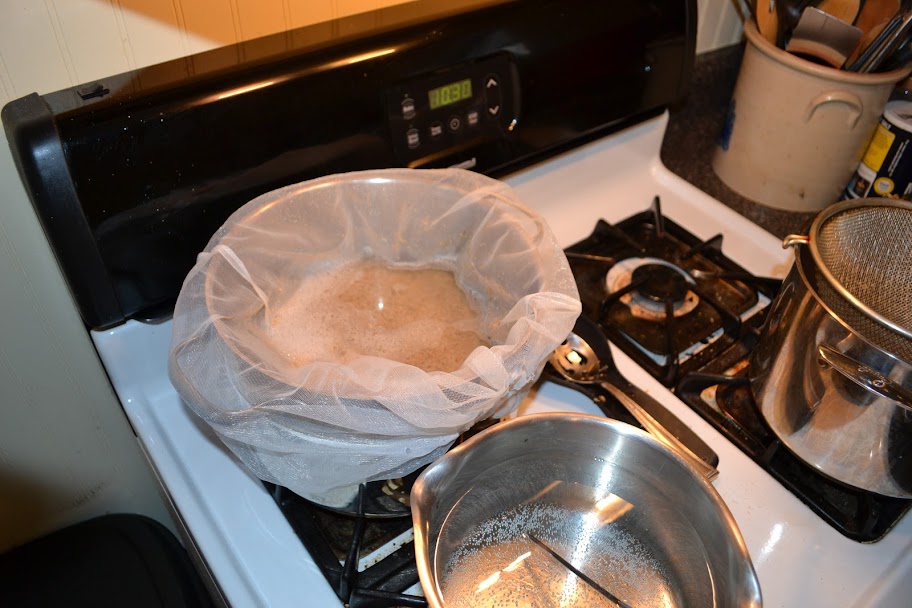

The sparge water

Chilling down 1 gallon of wort

Afterwards, not wanting to waste anything, I did another mini-mash with 1 lb of 2 row and 1/2 lb of Munich and 1/2 lb of Honey Malt, combined it with the worts from the experiments and boiled around 3.5 gallons (I didn't want to push the limits of my old 5 gallon extract kettle - I didn't feel like trudging out in the snow to fire up the AG rig). Added 2 oz of Amarillo leaf for 60 minutes and then another 1 oz at 5 minutes. I then topped off with water, which unfortunately made the post-boil OG come out to 1.026 Very small beer it is! Like I said it was more to not waste anything, we'll see how it tastes.

Very small beer it is! Like I said it was more to not waste anything, we'll see how it tastes.

Thanks for looking!

I decided to do an experiment with milling grain (I have a Barley Crusher) at a few different settings, mashing for one hour, sparging and then taking a gravity reading.

My process was:

#1 Mill grains (I milled all three batches at the beginning)

#2 Place crushed grains into paint strainer bag in 6 quart pot.

#3 Heat up strike water to 167

#4 Add strike water to pot with grains, maintain temp ~152 degrees for 60 minutes, stirring every 10 minutes.

#5 Pull bag out and let excess wort drain back into pot.

#6 Heat up sparge water to 180 (so it was ready in time)

#7 Once the mash has drained from the bag (under five minutes), put the bag in another pot and add the sparge water. Stir

#8 Let sparge pot sit for 5 minutes

#9 Drain as I did in Step #5

#10 Add sparge pot wort to mash pot wort to make 1 gallon

#11 Chill in ice-water bath to 100 degrees

#12 Take hydro reading.

2 lbs of 2 row mashed for 60 minutes and then sparged with enough water to make 1 gallon (2.5 quarts) at 100% efficiency would be 1.072

The number in parentheses is what I got when changing the Efficiency % to match what I got on the gravity reading.

My findings:

.035" yielded 1.044 - adjusted for temp to 1.048 (66% efficiency)

.032" yielded 1.049 - adjusted for temp to 1.053 (73% efficiency)

.030" yielded 1.051 - adjusted for temp to 1.055 (75% efficiency)

(Since I took the hydro readings at 100 degrees I used http://www.brewersfriend.com/hydrometer-temp/ to adjust hydro readings for temp)

Should I have taken the hydro reading just from the mash instead?

Of course the downfalls of this experiment are that:

#1 This was mash efficiency and not brewhouse efficiency

#2 As I did this on the stovetop with smaller pots it is not representative of what my system will get - concerning issues of if the crush is too fine there being a stuck sparge.

Some pictures of the process -

The grain crushed with the mill set at .035"

And here the .032" grain

And now the .030" grain

My mash setup

The sparge water

Chilling down 1 gallon of wort

Afterwards, not wanting to waste anything, I did another mini-mash with 1 lb of 2 row and 1/2 lb of Munich and 1/2 lb of Honey Malt, combined it with the worts from the experiments and boiled around 3.5 gallons (I didn't want to push the limits of my old 5 gallon extract kettle - I didn't feel like trudging out in the snow to fire up the AG rig). Added 2 oz of Amarillo leaf for 60 minutes and then another 1 oz at 5 minutes. I then topped off with water, which unfortunately made the post-boil OG come out to 1.026

Thanks for looking!