phendog

Well-Known Member

- Joined

- Jun 1, 2016

- Messages

- 184

- Reaction score

- 50

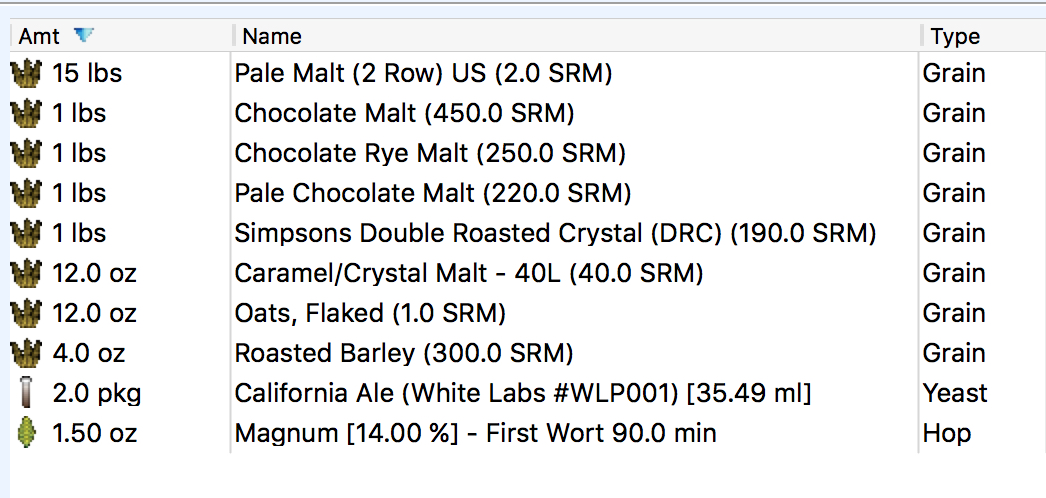

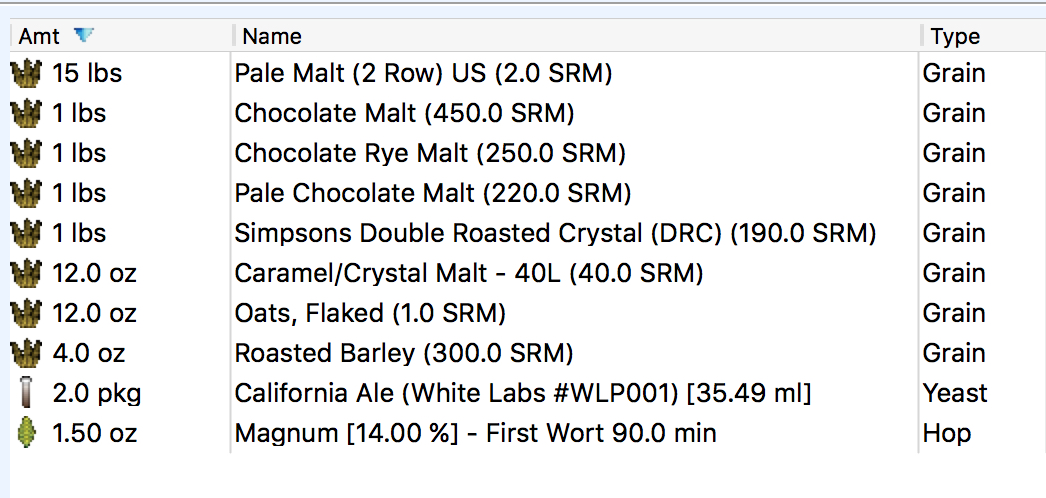

I am brewing a big Imperial Stout tomorrow. Grain bill attached.

Due to the amount of grain I'm using, I think I can get a second batch out of it - maybe 3 or 4 gallons for a 4 to 5% abv Session Stout.

Was thinking that after I've collected all the wort I need for my first boil (5.5gal batch), I could stop collection and start my first boil. Then, either:

1. Continue to sparg my mash until I've collected enough for my 2nd batch, or

2. Do two batch sparges and collect for boil

What would you do, or am I completely off base.

Due to the amount of grain I'm using, I think I can get a second batch out of it - maybe 3 or 4 gallons for a 4 to 5% abv Session Stout.

Was thinking that after I've collected all the wort I need for my first boil (5.5gal batch), I could stop collection and start my first boil. Then, either:

1. Continue to sparg my mash until I've collected enough for my 2nd batch, or

2. Do two batch sparges and collect for boil

What would you do, or am I completely off base.