pilotdane

Well-Known Member

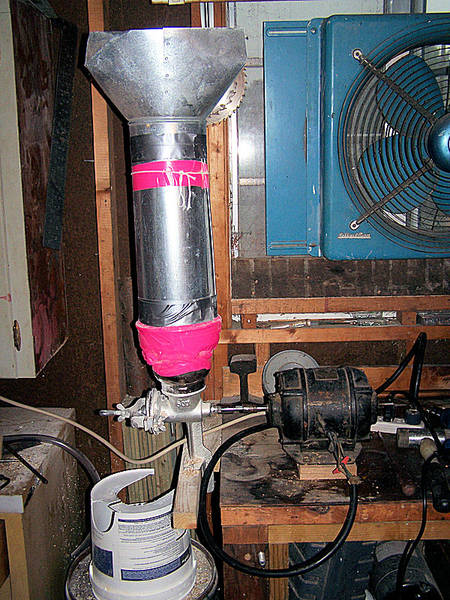

My goal was to build a nice crusher on a moderate budget. Something that could accommodate larger batches without headache should I move up to brew with the bigger boys.

My father had a scrap piece of 3/4" thick plastic which I used for the mounting base.

I found the 1/3hp motor and gearbox new, old stock on Ebay. The gearbox is a variable speed Zero-Max that can deliver full torque from zero up to full rpm's (400) and anywhere in between.

The mill is a Monster Mill three roller MM3 with 1.5" diameter rollers connected with a Lovejoy shaft coupler.

My father had a scrap piece of 3/4" thick plastic which I used for the mounting base.

I found the 1/3hp motor and gearbox new, old stock on Ebay. The gearbox is a variable speed Zero-Max that can deliver full torque from zero up to full rpm's (400) and anywhere in between.

The mill is a Monster Mill three roller MM3 with 1.5" diameter rollers connected with a Lovejoy shaft coupler.