Ace_Club

Well-Known Member

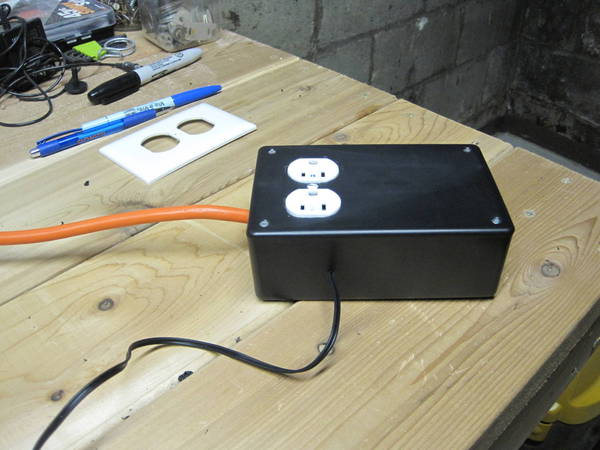

I'm in the process of switching from extract, basement-ambient-temp brewing to all-grain, controlled-temp brewing. I'm currently working on constructing the fermentation chamber.

The outside dimensions of the chamber are 48" x 48" x 43". I plan to add approximately 3.5" of rigid foam board insulation, which will then be covered with FRP.

The chamber will be kept at 60F and cooled utilizing a standard mini fridge. Here are some pics of the current progress. Next step is adding the insulation.

The outside dimensions of the chamber are 48" x 48" x 43". I plan to add approximately 3.5" of rigid foam board insulation, which will then be covered with FRP.

The chamber will be kept at 60F and cooled utilizing a standard mini fridge. Here are some pics of the current progress. Next step is adding the insulation.