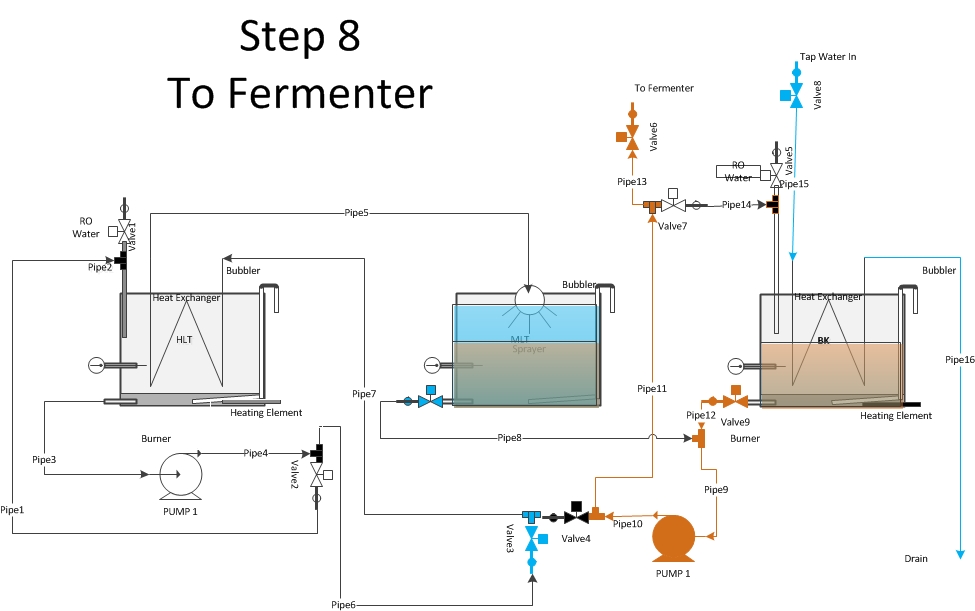

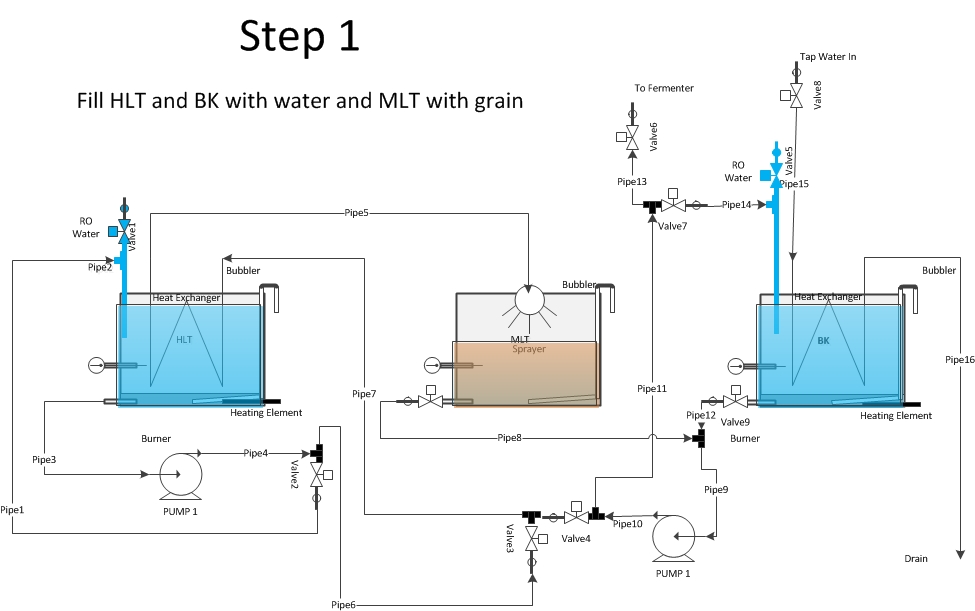

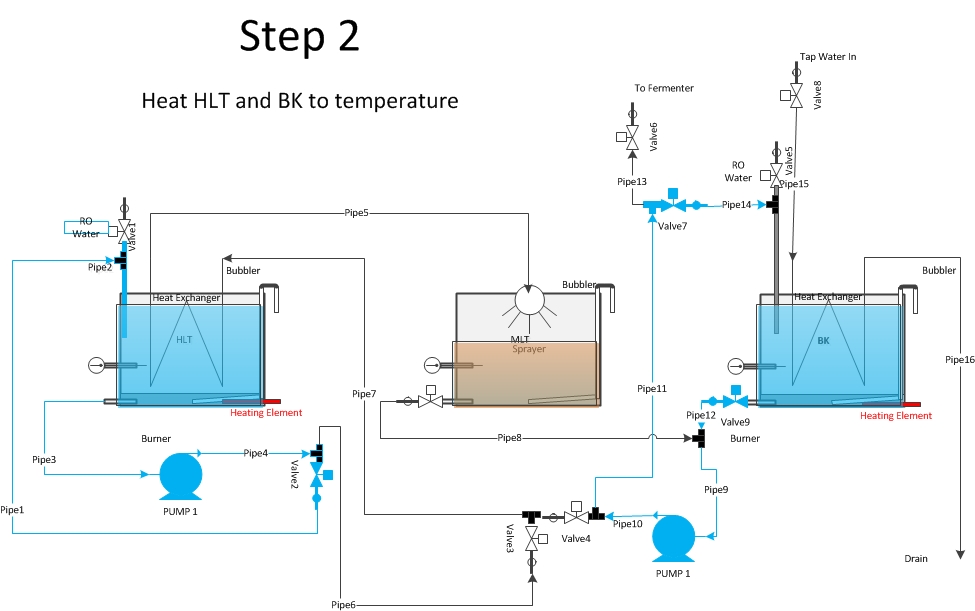

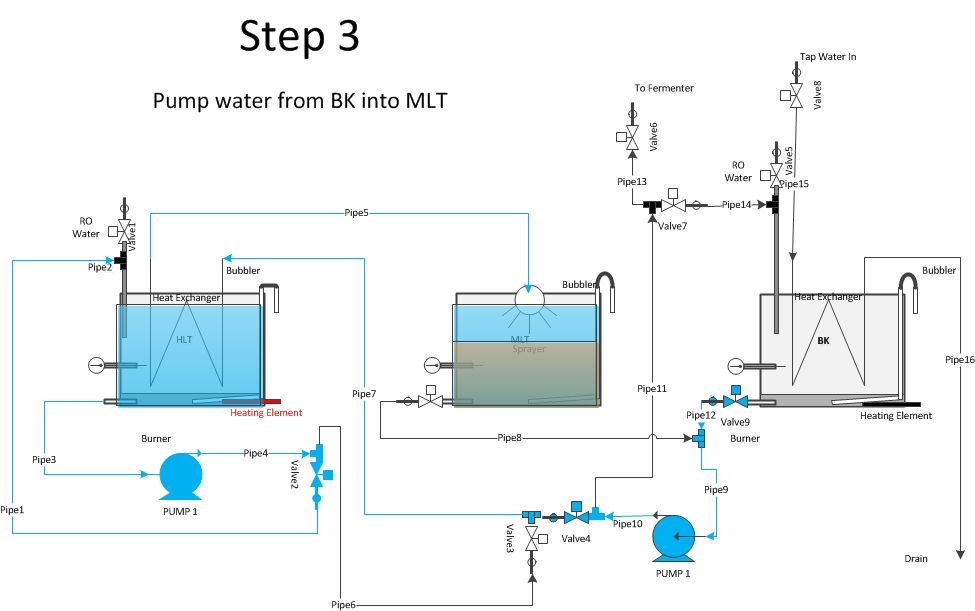

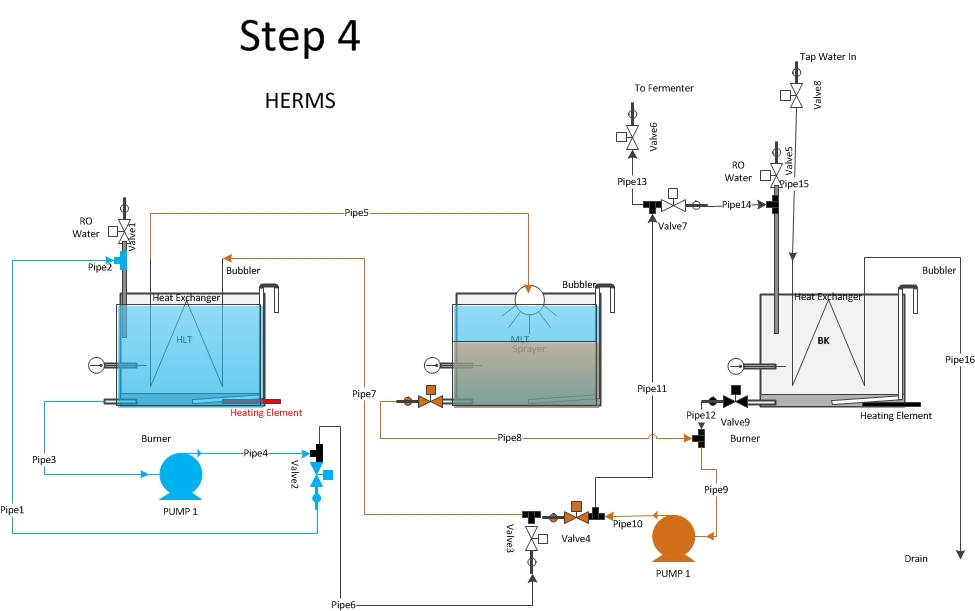

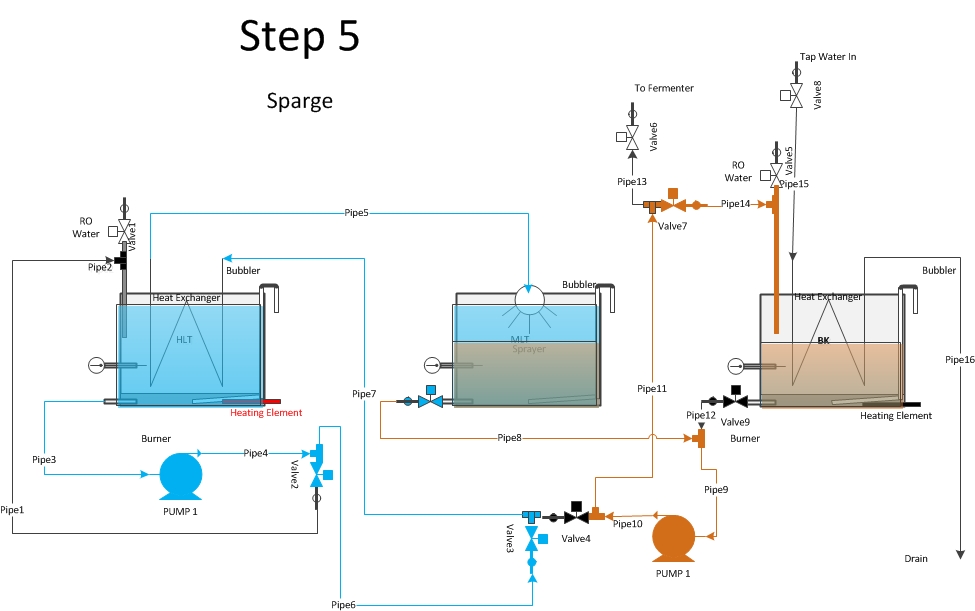

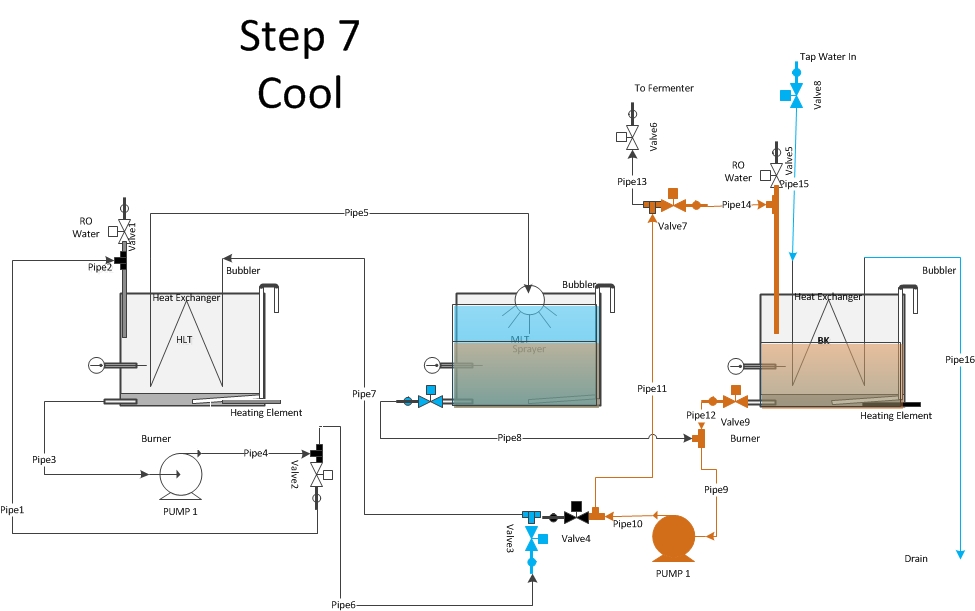

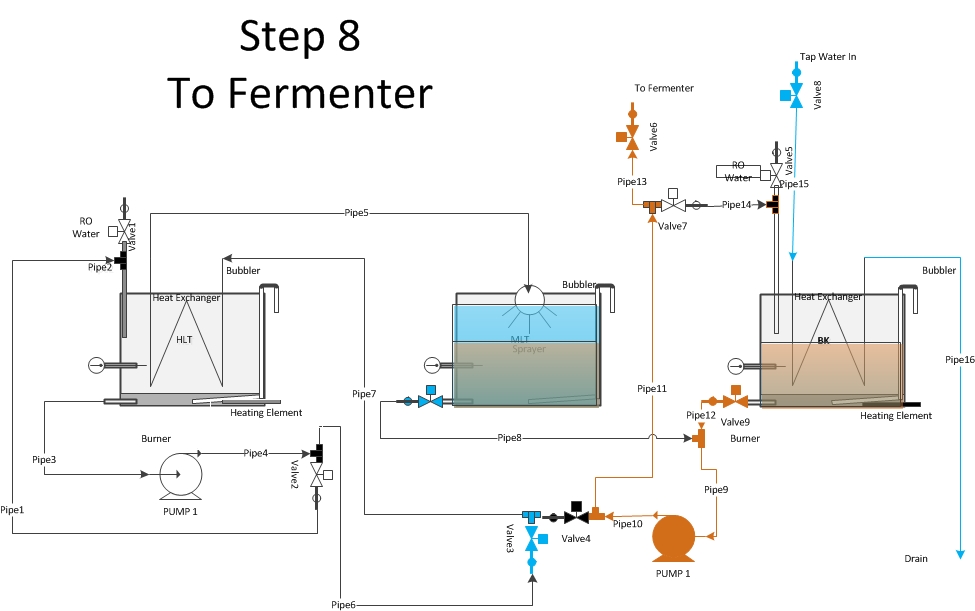

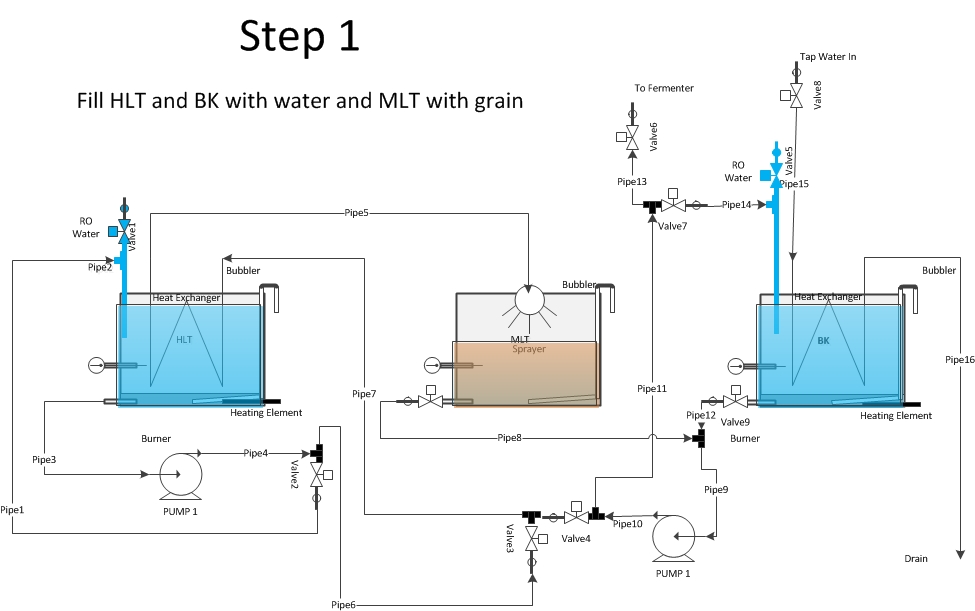

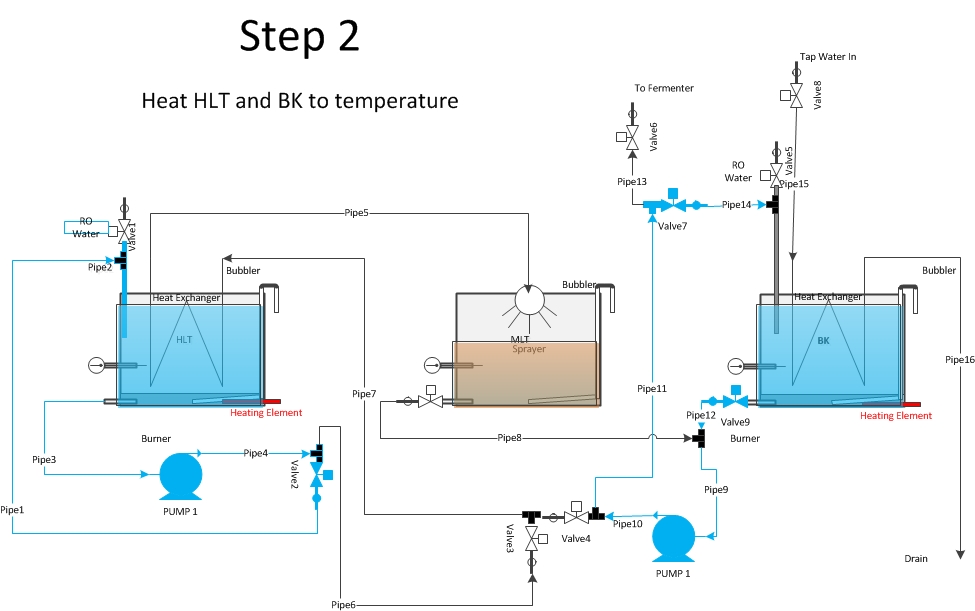

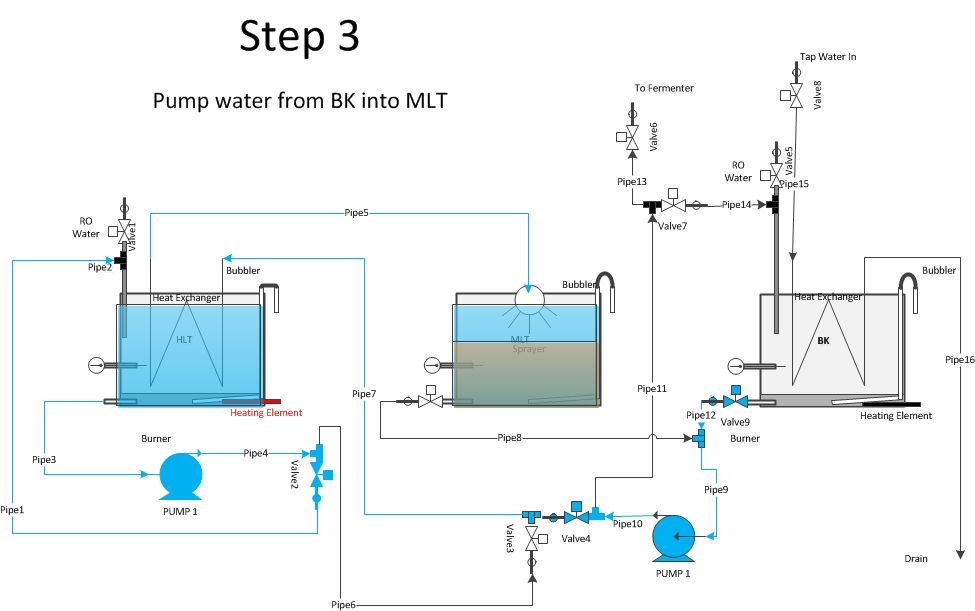

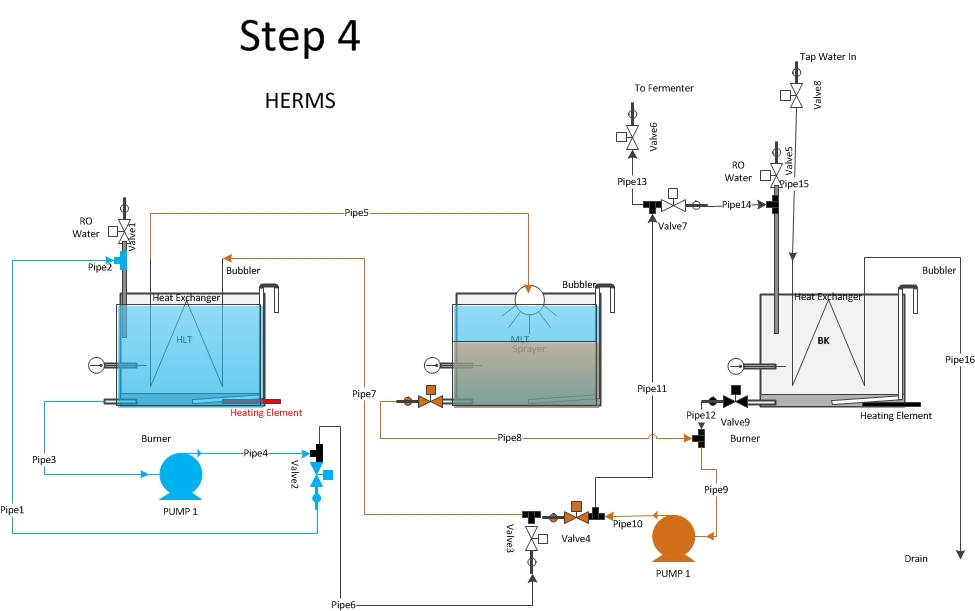

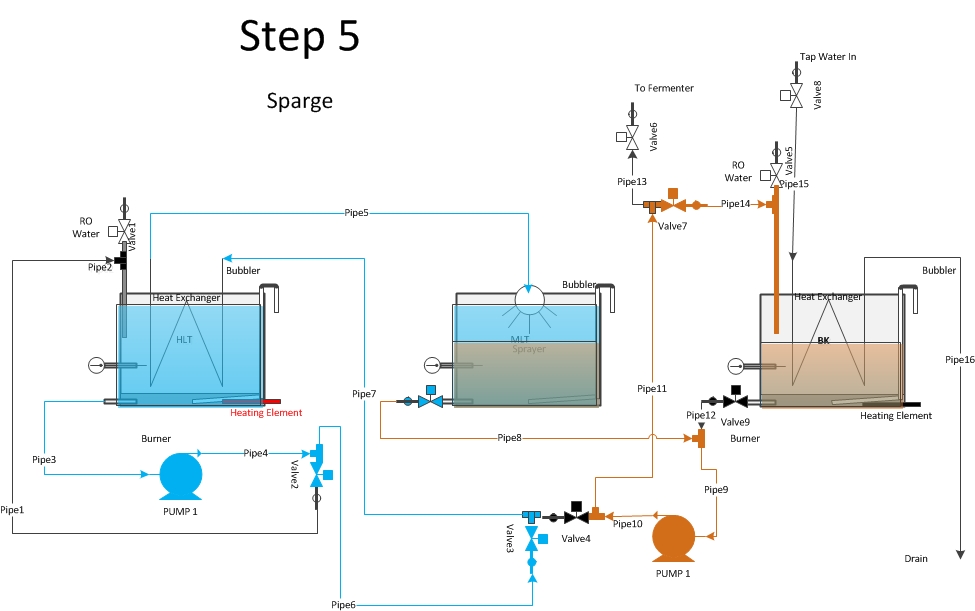

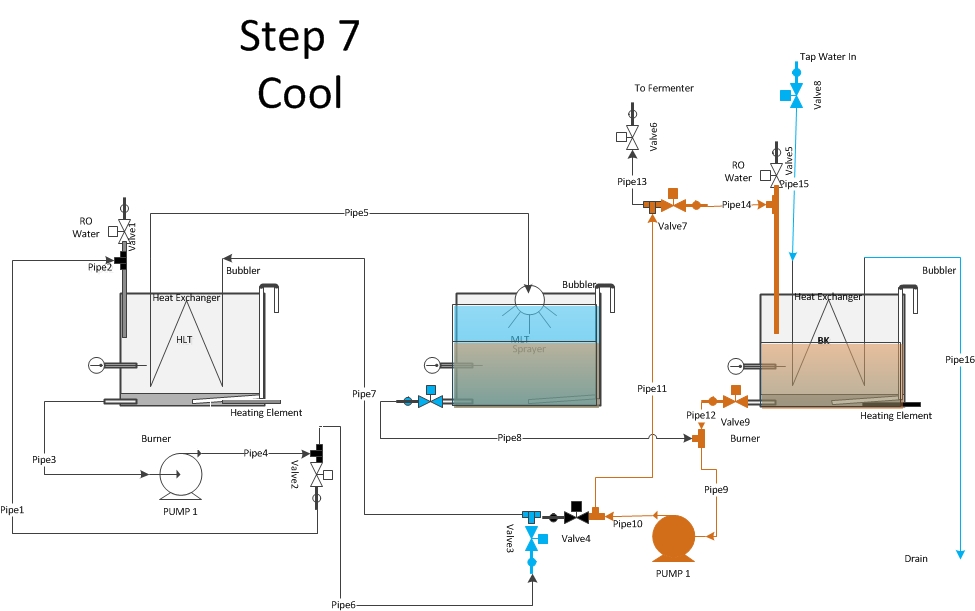

I decided to build my own automated brew system. Im going to go with a HERMS electric setup that can handle 10 gallons (Im going to use 15 gallon pots). Below is my process. I think I have everything covered but always welcome opinions/suggestions. I am also going to use a .NET MF (C#) based controller which looks to be unique from the other systems out there.

[i

[i

[i

[i

[i

[i

[i

[i

[i

[i

[i

[i

[i

[i

[i

[i