Browningbuck

Well-Known Member

- Joined

- Nov 27, 2014

- Messages

- 132

- Reaction score

- 48

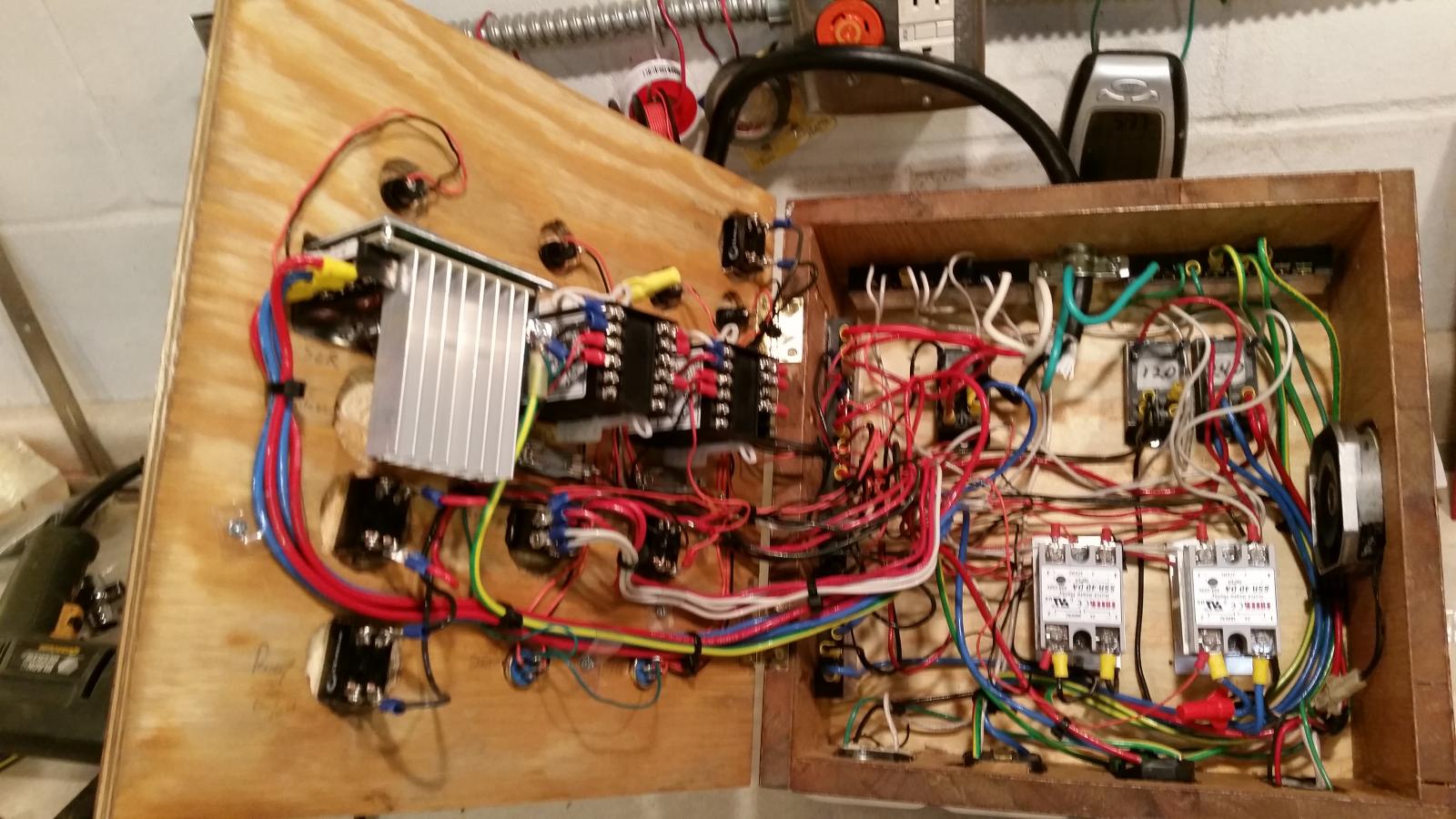

thanks, also you cant see it really but the plates are carbon fiber that i put the vinyl stickers on.

i cut carbon fiber sheet then cut vinyl stickers placed them on the plate and clear coated them all... i still need to do a few more to finish it up.Where did you get those labels?