brauhausjoe

Well-Known Member

This started here: https://www.homebrewtalk.com/f51/drilling-my-keggle-holes-130969/ The end of the post....page 3 as of today.

For those folks who own welded keggles, are your fittings flush or half in?

For the Half In's how does the inside of your weld/keggle look? I have a problem, even after purging, verifying that the inside of the weld is clean all the way around.

For the flush, I know it is clean all the way around and I verify my threads work inside and out. Have you had issues? If so please let me know what they are.

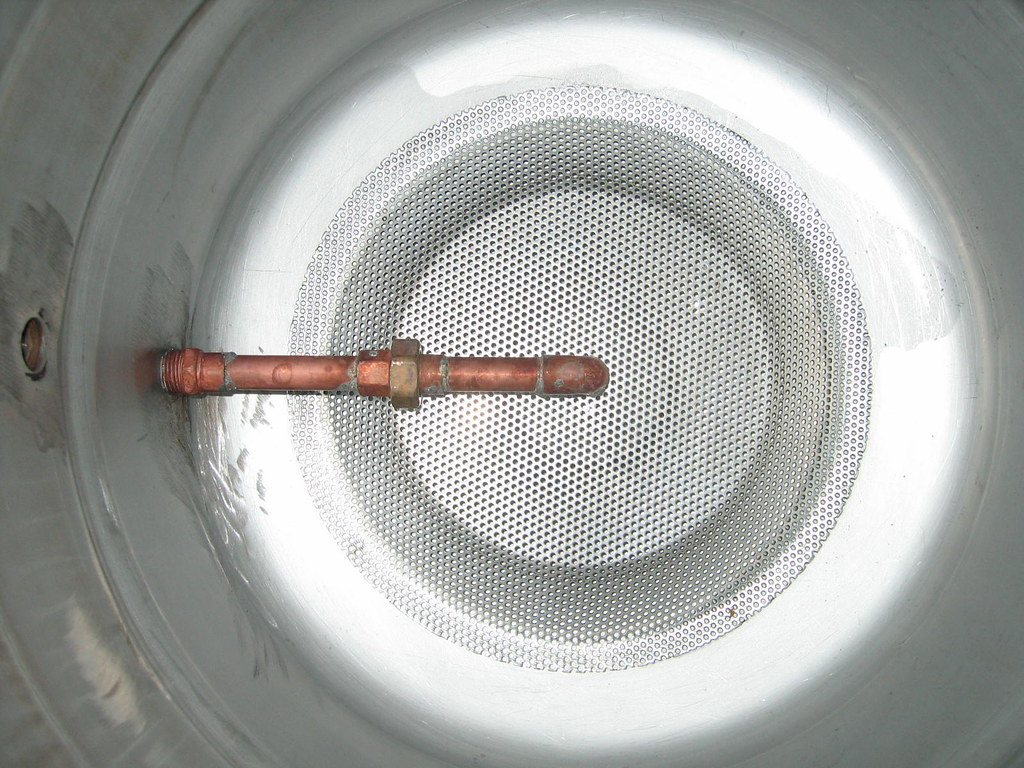

Here are some images of my flush welds:

and

For those folks who own welded keggles, are your fittings flush or half in?

For the Half In's how does the inside of your weld/keggle look? I have a problem, even after purging, verifying that the inside of the weld is clean all the way around.

For the flush, I know it is clean all the way around and I verify my threads work inside and out. Have you had issues? If so please let me know what they are.

Here are some images of my flush welds:

and