DirtyPolock

Well-Known Member

So thanks to my SWMBO for getting me my starter kit and this forum, you are quickly draining my funds, but I am loaded with excitement for every new project.

I have begun my keezer conversion today. I will try to post updates as I go along. It will not be a daily event but I am sure at least something will happen at least twice a week. I may ask some questions along the way but this forum has helped me out tremendously. Once I post to the show us your kegerator thread I will surely become a premium member for all your guys help.

Step 1: Purchase chest freezer - Kenmore 8.8 cu ft - black

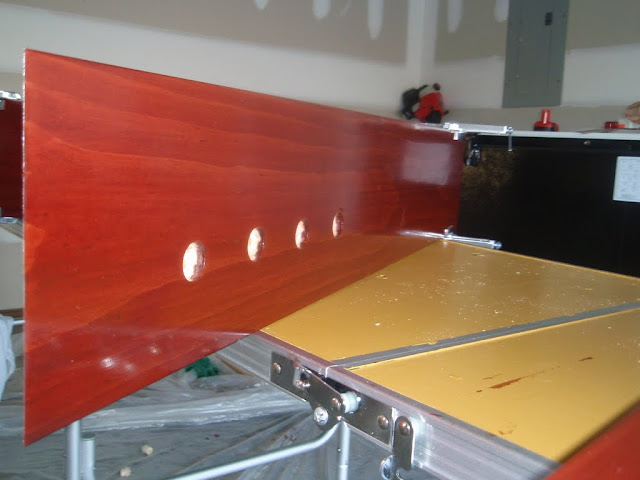

Step 2: Purchase pine lumber, wood stain, and other maintenance items for all parts needed.

Step 3: Mider cut all parts to hopefully give a smooth look. This was my first time doing any wood work so we'll see what the finished product looks like.

Step 4: Sand all wood before staining

Step 5: I used wood staining pre-treatment and then quickly stained with Cabot cherry wood stain. I will let dry for about 48 hours before the second coat

I have begun my keezer conversion today. I will try to post updates as I go along. It will not be a daily event but I am sure at least something will happen at least twice a week. I may ask some questions along the way but this forum has helped me out tremendously. Once I post to the show us your kegerator thread I will surely become a premium member for all your guys help.

Step 1: Purchase chest freezer - Kenmore 8.8 cu ft - black

Step 2: Purchase pine lumber, wood stain, and other maintenance items for all parts needed.

Step 3: Mider cut all parts to hopefully give a smooth look. This was my first time doing any wood work so we'll see what the finished product looks like.

Step 4: Sand all wood before staining

Step 5: I used wood staining pre-treatment and then quickly stained with Cabot cherry wood stain. I will let dry for about 48 hours before the second coat