klyph

Well-Known Member

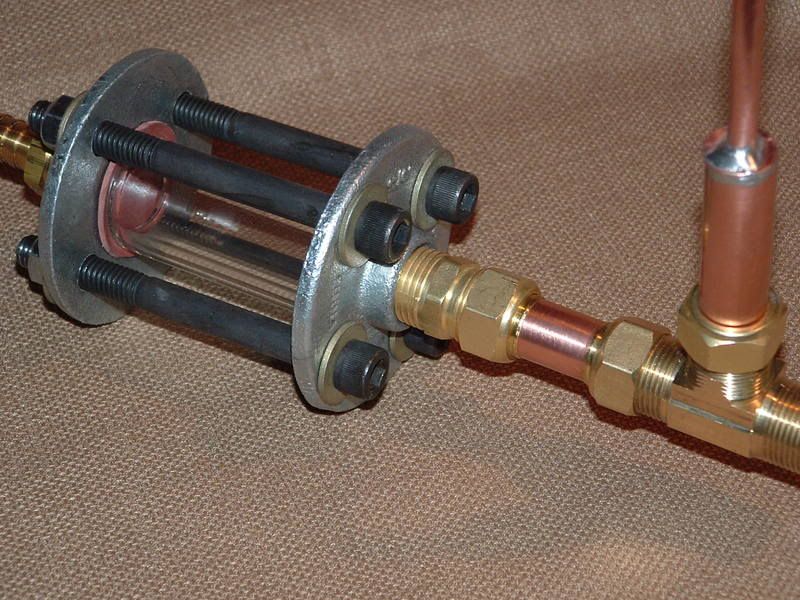

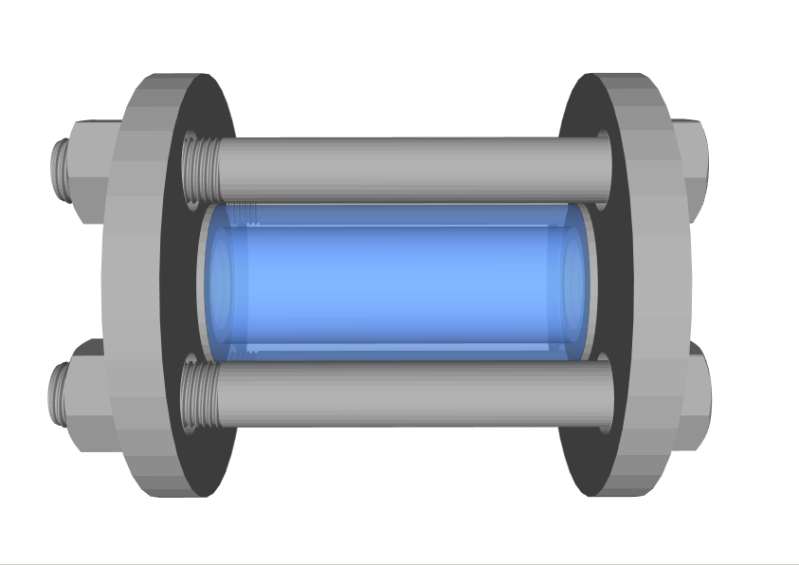

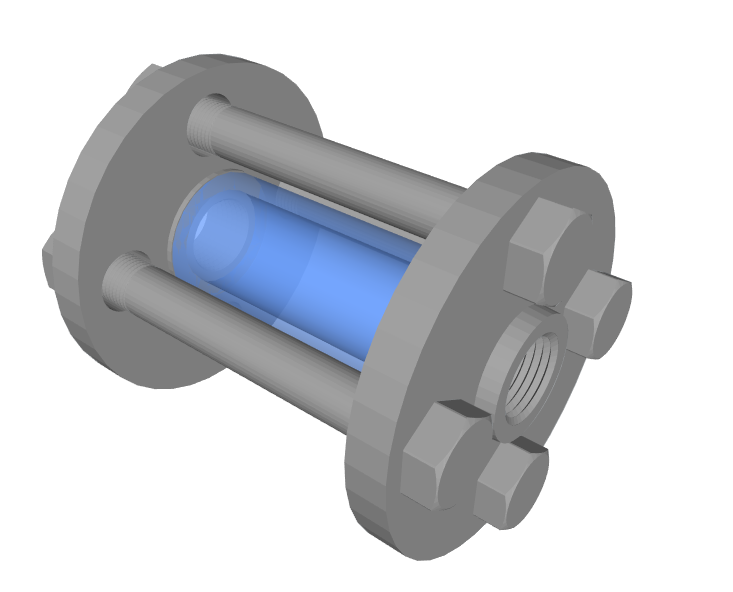

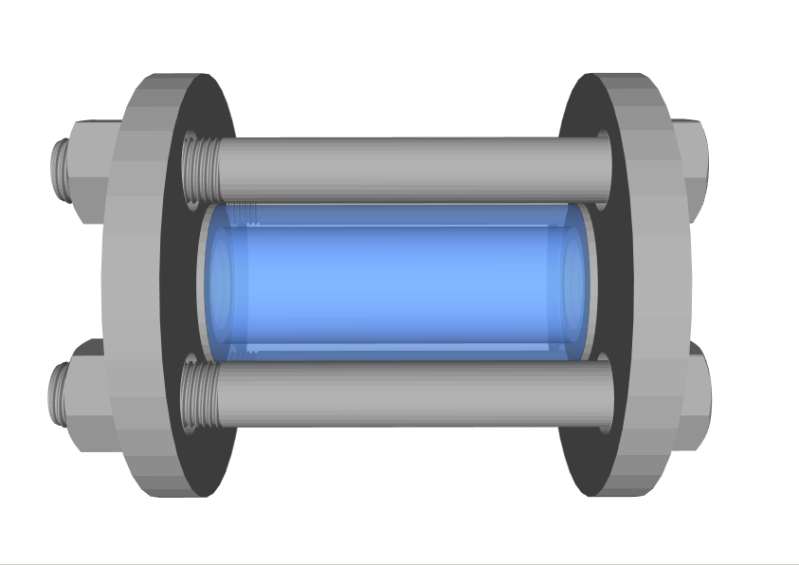

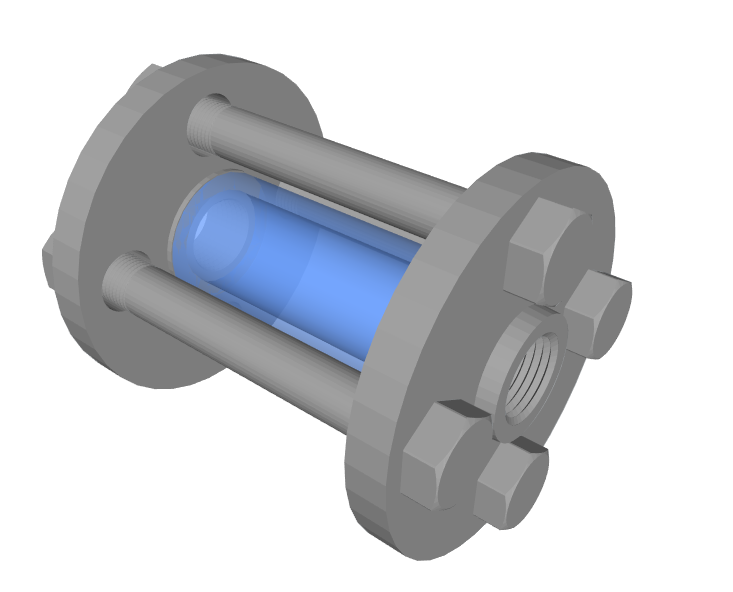

After looking at the blingy tri clamp sight glasses that are going for $80, I thought I could build one that uses 1/2" NPT for a lot cheaper. I made this assembly in google sketchup from parts off of McMaster-Carr to see how it would look and fit together:

The model can be downloaded from the 3D warehouse here:

http://sketchup.google.com/3dwarehouse/details?mid=1d0392606df439ad27cf7a67d12bc843&prevstart=0

I think the NPT fittings will work better for most people's homebrew rigs, and the price breakdown was encouraging as well.

The flanges:

http://www.mcmaster.com/#44685K11

Cost $15.73 x 2 = $31.46

I got a quote on the borosilicate tubing for about $10 per piece if I order a whole stick (18 pieces).

The nuts, bolts and silicone gaskets probably add another 5-10 bucks.

So all together it looks like these can be built for <$50 without any bulk discounts. The flanges are the most expensive part, and I figure we should be able to find a supplier that can do better than McMa$ter. I contacted Wayne at Bargainfittings to see what he could do about pricing for a bulk order of SS flanges, and I'm waiting to hear back from him. I was hoping to at least be half as expensive as the tri clamp version from St. Pats that goes for $80.

Basically the point of this thread is to gauge interest in this project and hopefully fish out a supplier for the parts that will make it cost effective.

Please reply with whether you would seriously consider purchasing a SS 1/2" NPT sight glass for about $40 or let me know how much you think is a reasonable price point. Extra credit to anyone who can find the flanges cheaper.

Thanks

The model can be downloaded from the 3D warehouse here:

http://sketchup.google.com/3dwarehouse/details?mid=1d0392606df439ad27cf7a67d12bc843&prevstart=0

I think the NPT fittings will work better for most people's homebrew rigs, and the price breakdown was encouraging as well.

The flanges:

http://www.mcmaster.com/#44685K11

Cost $15.73 x 2 = $31.46

I got a quote on the borosilicate tubing for about $10 per piece if I order a whole stick (18 pieces).

The nuts, bolts and silicone gaskets probably add another 5-10 bucks.

So all together it looks like these can be built for <$50 without any bulk discounts. The flanges are the most expensive part, and I figure we should be able to find a supplier that can do better than McMa$ter. I contacted Wayne at Bargainfittings to see what he could do about pricing for a bulk order of SS flanges, and I'm waiting to hear back from him. I was hoping to at least be half as expensive as the tri clamp version from St. Pats that goes for $80.

Basically the point of this thread is to gauge interest in this project and hopefully fish out a supplier for the parts that will make it cost effective.

Please reply with whether you would seriously consider purchasing a SS 1/2" NPT sight glass for about $40 or let me know how much you think is a reasonable price point. Extra credit to anyone who can find the flanges cheaper.

Thanks