JVD_X

Well-Known Member

Hi,

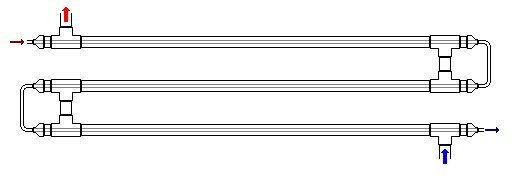

Has anyone used a counterflow chiller (e.g. chillzilla) in a RIMS setup using a low wattage element to heat the water (not the wort obviously) instead of putting a coil inside a kettle and using a bigger element as in a traditional HERMS?

I would like to move from my RIMS system to a HERMS system bu it seems to me it would be a lot more efficient heating the one or two gallons of water around a coil instead of heating 15 gallons inside a keggle.

Has anyone used a counterflow chiller (e.g. chillzilla) in a RIMS setup using a low wattage element to heat the water (not the wort obviously) instead of putting a coil inside a kettle and using a bigger element as in a traditional HERMS?

I would like to move from my RIMS system to a HERMS system bu it seems to me it would be a lot more efficient heating the one or two gallons of water around a coil instead of heating 15 gallons inside a keggle.