Roadie

Well-Known Member

Whoo hoo! Brew party at John's house!

Woohoo! Pictures or it didn't happen! (err, wait...)I just got an e-mail this afternoon from Spike Innovations and they are shipping my control box, temp probes, and power cord today! It should arrive on Wednesday 11/25/15 (the day before Thanksgiving). Looks like I'll be breaking in the new system and brewing that weekend!! Thanks Mike and Kal, it will be Christmas at my house a month early this year!

Whoo hoo! Brew party at John's house!

Woohoo! Pictures or it didn't happen! (err, wait...)

Kal

Cool! I always like those... Here's another:I will make sure to post some pics when the box arrives! Maybe do some unboxing photos......

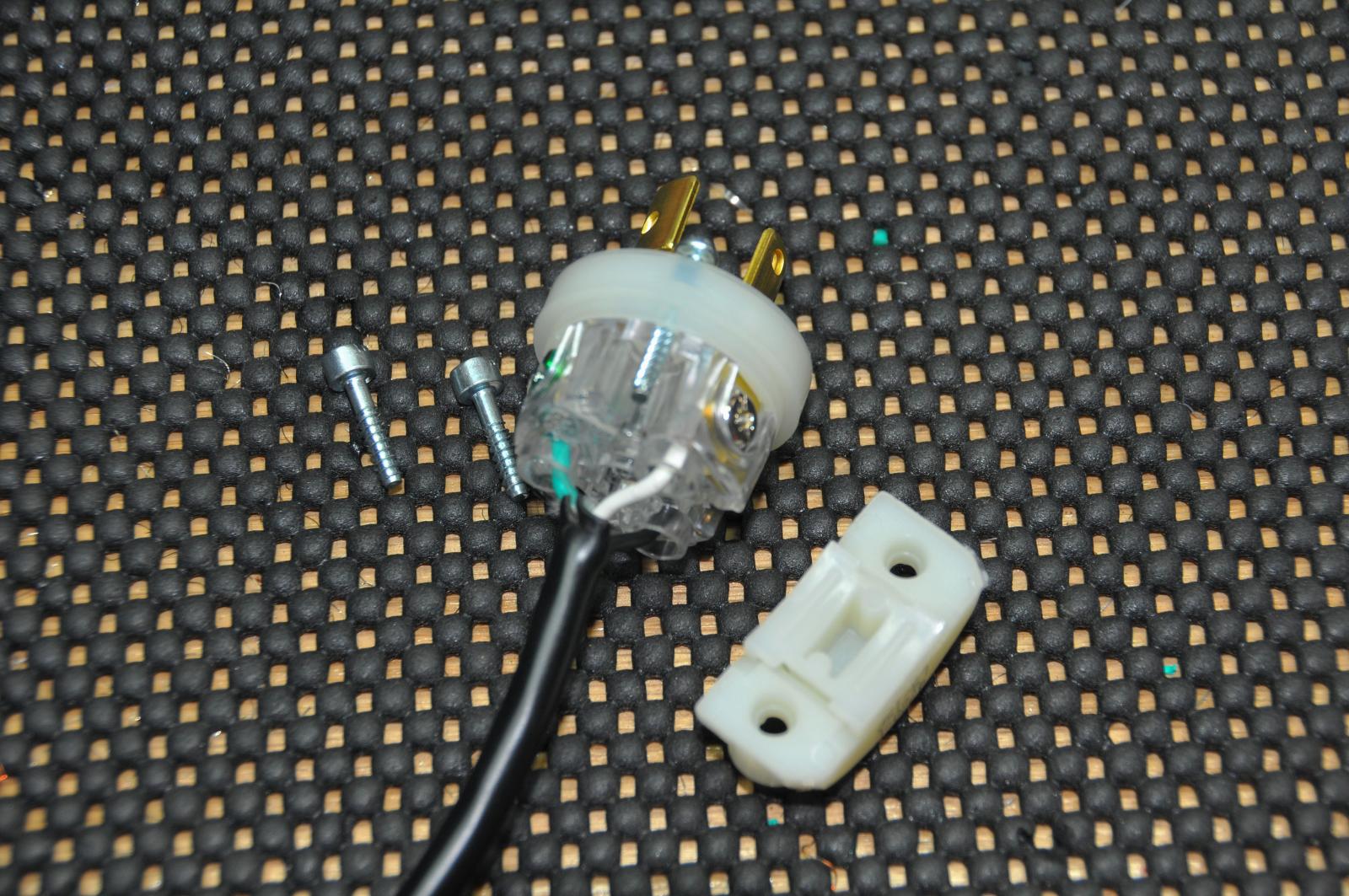

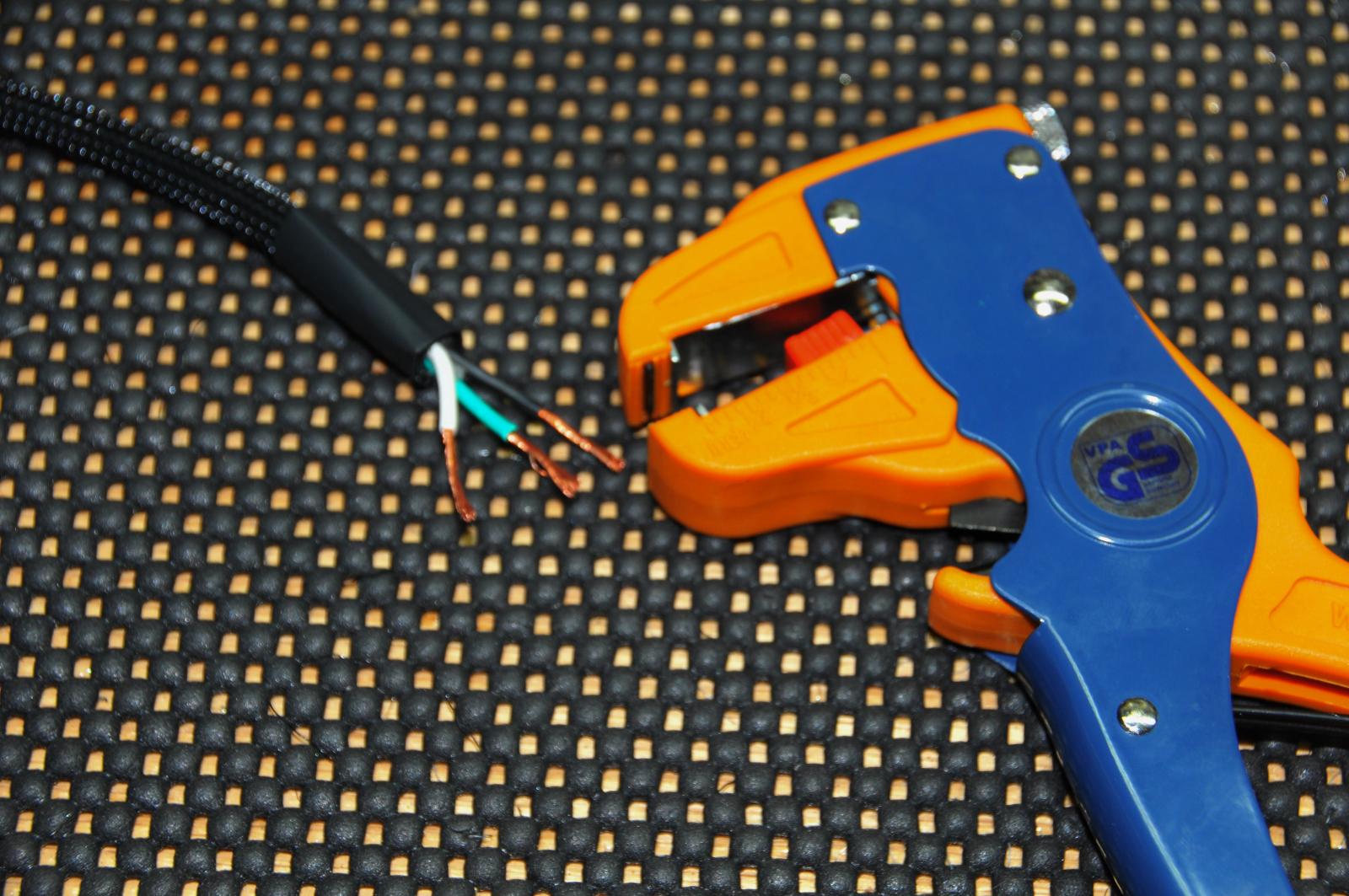

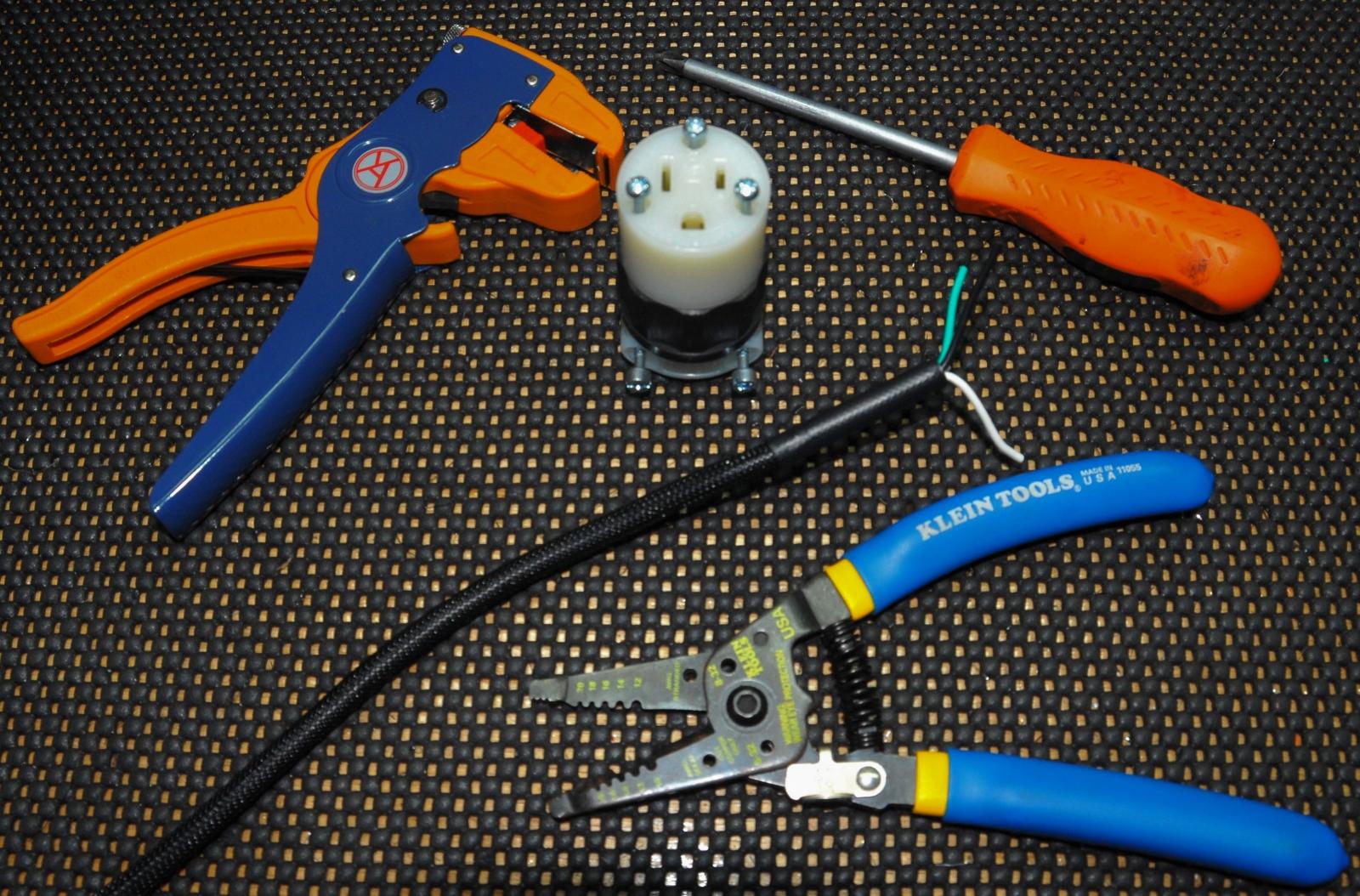

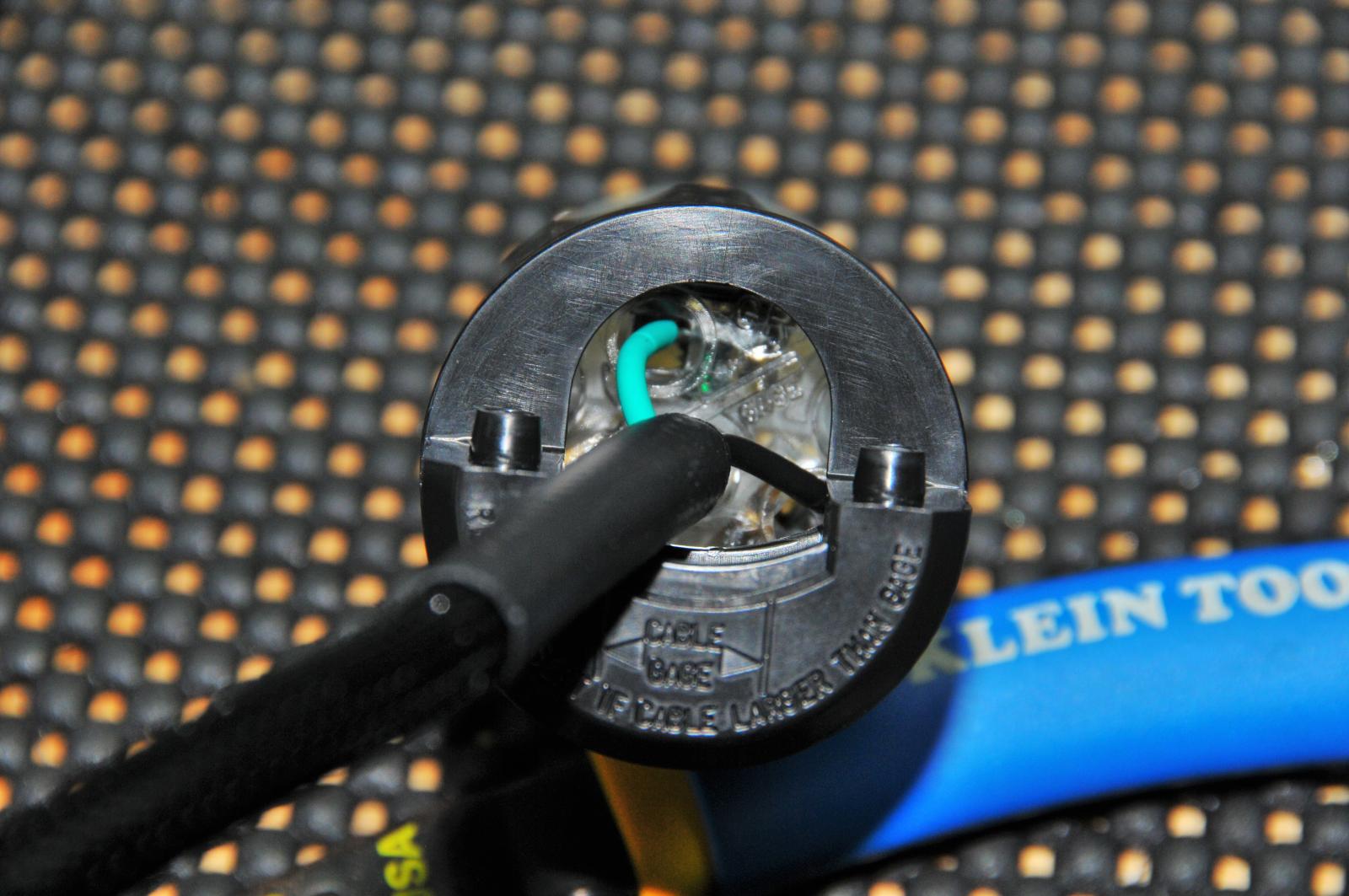

Nice job on the pump cords. I think you'll be glad you did it that way down the road. Control panel arrives tomorrow? Score! And here I was just excited that the sharpening stones for my new Gyuto would be here on Wednesday. Your control panel puts that in perspective!

Me too!

A little birdie tells me the panel has arrived safely... awaiting pics!

Kal

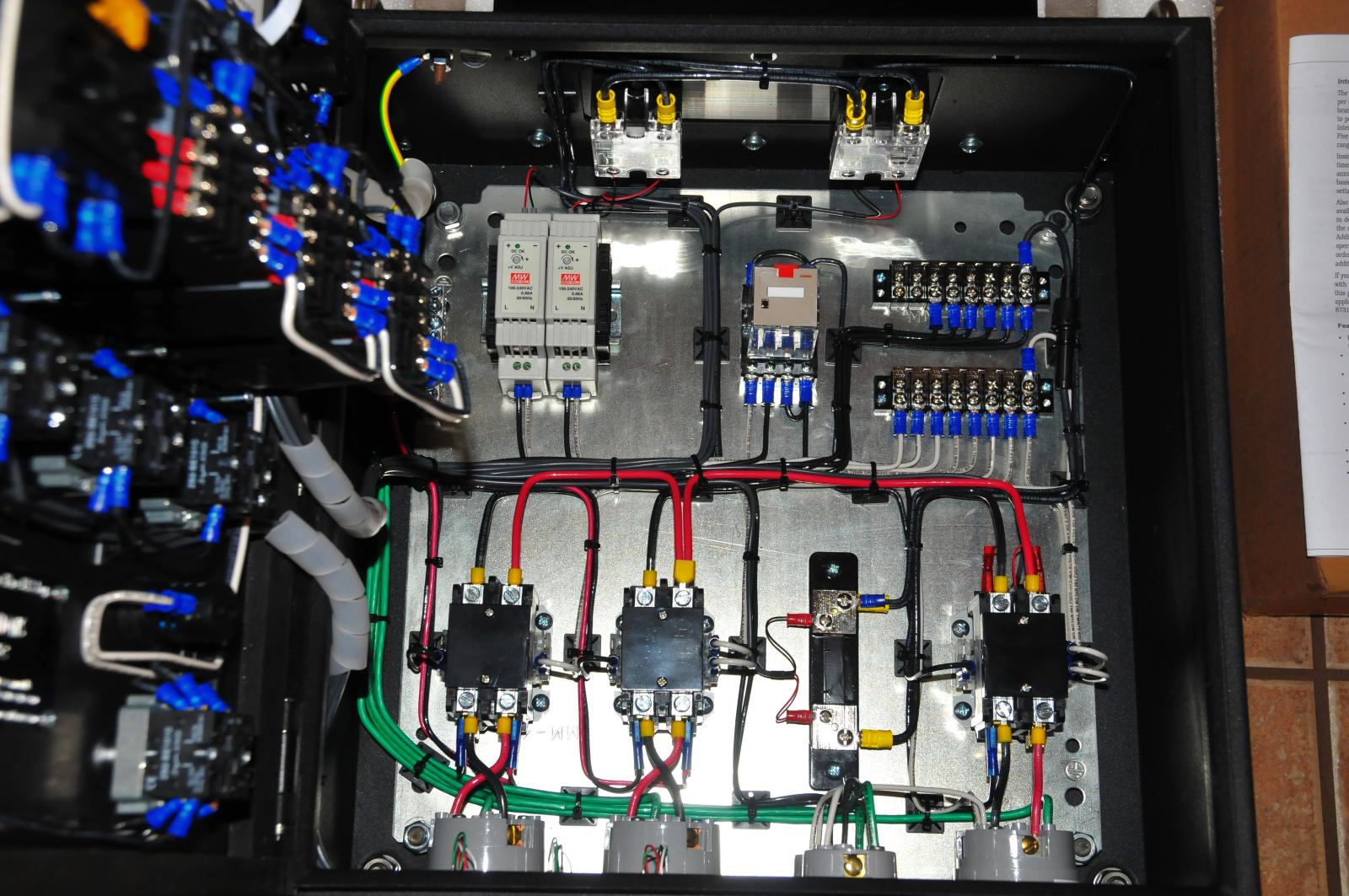

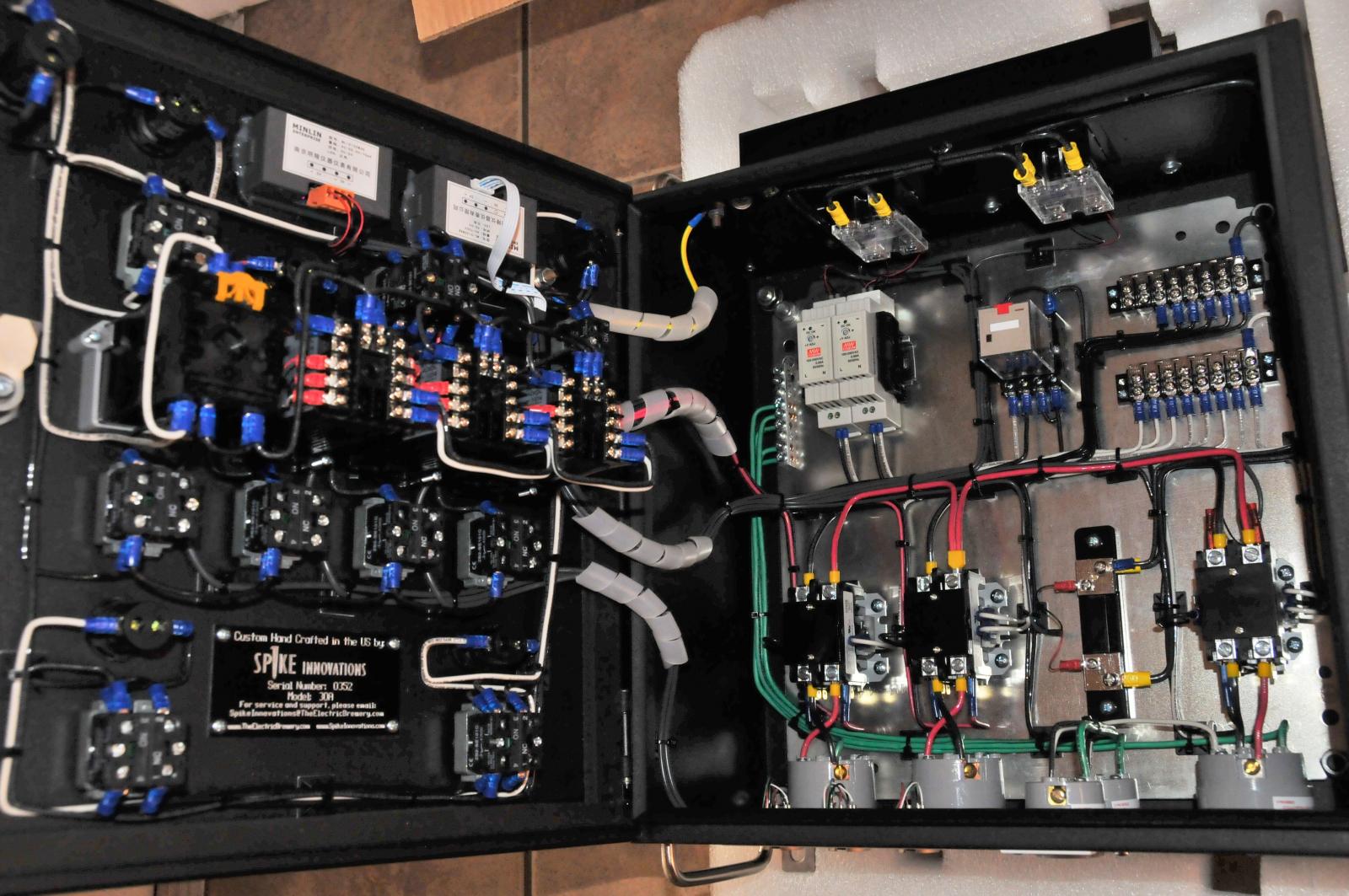

I'm glad your happy John and that it all arrived safely!Kal you are the man! I can't get over the quality of the box, the texture of the powder coat is awesome, the wiring is so clean and tight, and you even used high quality Neutrik XLR connectors for the temp probes. Mike you did an outstanding job assembling this control box and it really is a pleasure to do business with company a solid as you guys.

Please make sure to heed the warning on the big label that came on the panel and double check all high voltage screw connections inside the panel with a screwdriver (basically make sure any big fat wire attached with a screw is tight).Now I have to calibrate the probes, do some tests and do a test run, and then I hope I can brew on Sunday!

I'm glad your happy John and that it all arrived safely!

Please make sure to heed the warning on the big label that came on the panel and double check all high voltage screw connections inside the panel with a screwdriver (basically make sure any big fat wire attached with a screw is tight).

There shouldn't be any issues but it's a double check we like people to do - just in case.

Happy brewing!

Kal

So did brew day happen?

Love those Kal panels from Spike..but looking i cant help but wonder why they twisted the black and red wires going to the element sockets? I mean it doesnt matter which one goes where to the element so i wonder why they cross them over eachother to put Red on the left instead of just going straight in like with the main power input connector.

Enter your email address to join: