CidahMastah

Well-Known Member

- Joined

- Nov 12, 2010

- Messages

- 4,201

- Reaction score

- 46

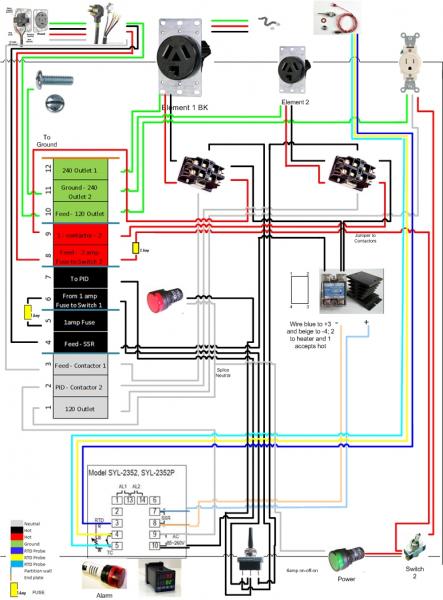

With the system you are about to put together (one contactor, one element, one PID, temp probe, pump outlet), the only thing you have to do to make it a HERMS system is put your immersion chiller down in the kettle and pump wort through it.

I have been brewing on my HERMS for a year now and I only have one electric kettle. I don't see the need to make a dedicated electric HLT. The only time I even need a third vessel is when draining my first runnings to the boil kettle (there's two vessels) and needing a place to hold some hot water (there's the third). At no other point is there a third vessel involved.

So are you suggesting to keep it simple as in the first schematic?

One issue I have been running into with my current set up is a lag time when I need to get the sparge water ready. So for example, we do the first runnings off a 10G batch, into the BK. When the mashtun is drained, I add sparge water to sit for 10 minutes and then drain into the BK. Then I fire up the BK and we are off to boil. But I am stuck using a 30qt aluminum pot on my stove (in the house) to get that up to the sparge temp because the BK is collecting wort. It takes forever in the house, like 20-30 minutes or more to get to 170F. I was thinking if I had a second element in a HLT, I could get the sparge water going at the same time that I am collecting my first runnings, and do it faster than I can on my stove.

ha

ha