WalterAtMarchPump

Well-Known Member

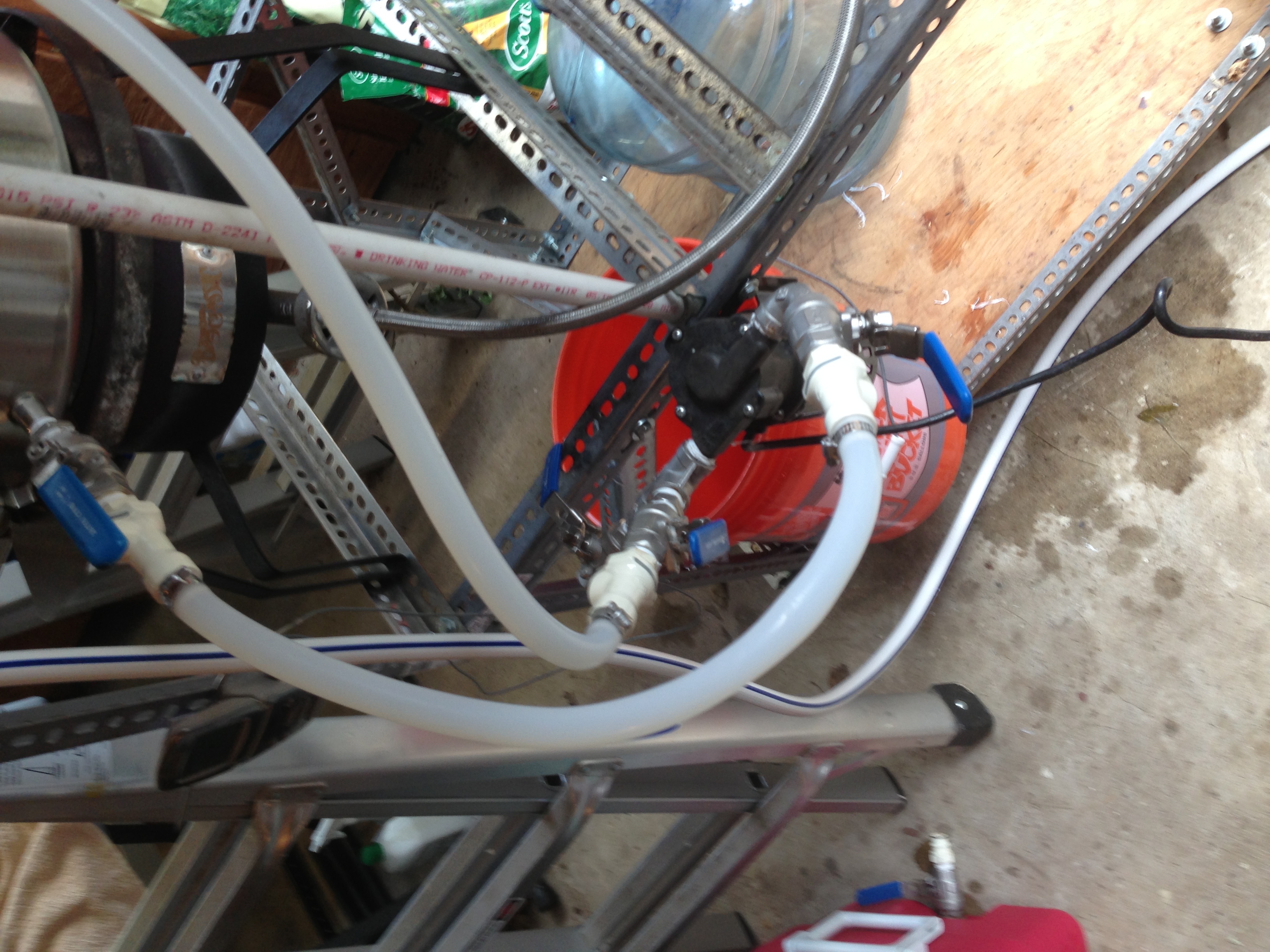

There are a few issues we have found over the years with beer brewers that seem to cause them problems. The most common is pump orientation. So i thought i would just go over the main points incase it help's someone tweak their system better or setup a new brew stand.

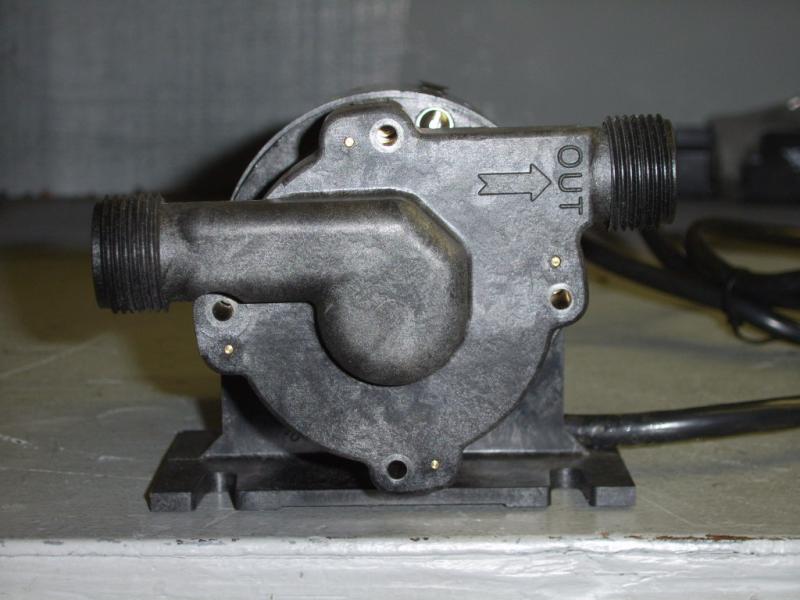

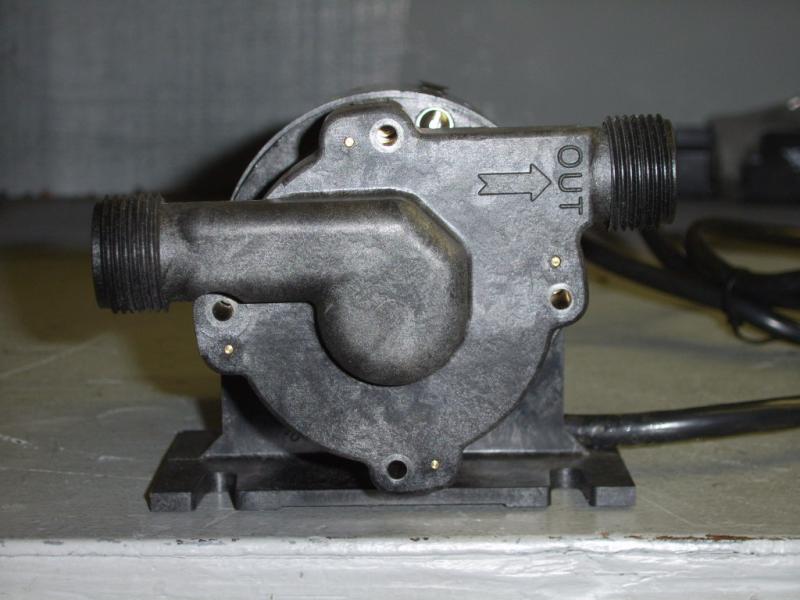

The first picture is usually how the pump comes straight out of the box. Pay no attention to the thread size as I just happen to take a custom one off the shelf here in the repair dept for this example. This one has 1" thread fittings on it.

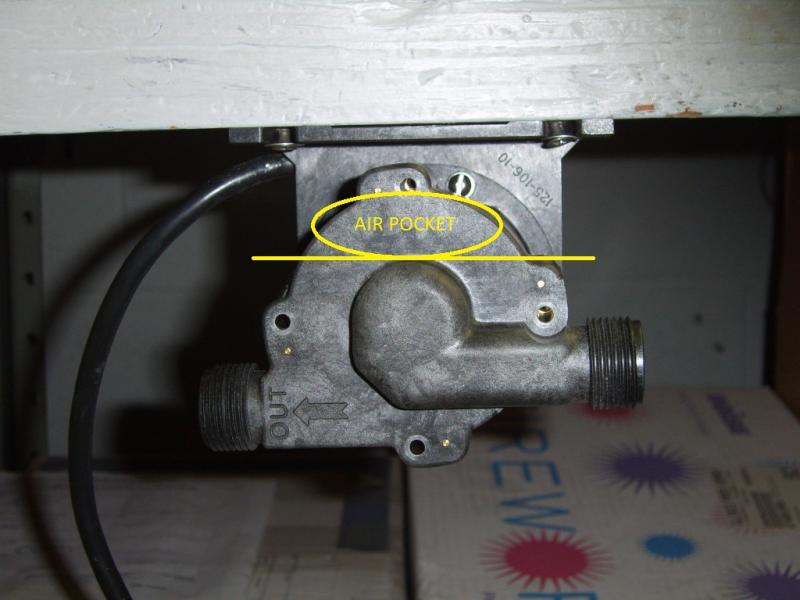

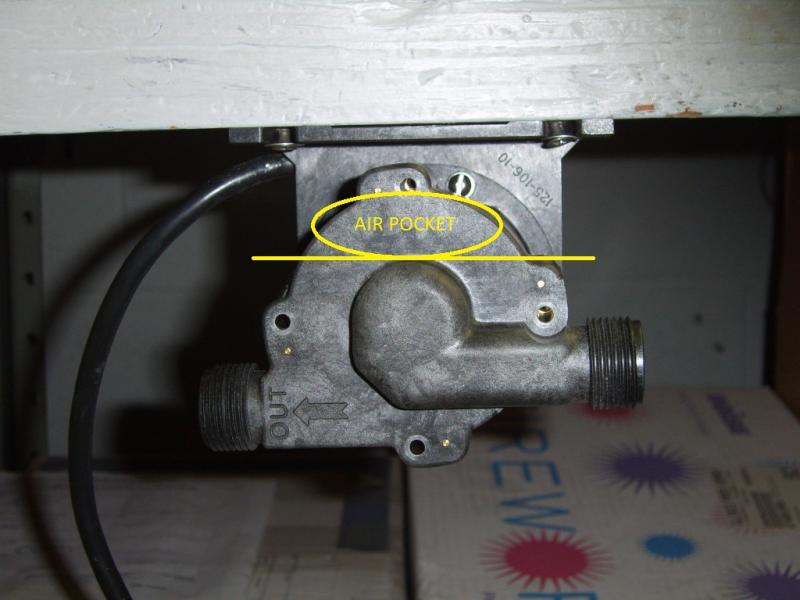

As you can see the outlet is on the right hand side of the picture and the inlet is on the left. The outlet is higher to allow air to escape out of the pump. Some brewers have mounted the pump upside down and that results in an air pocket being trapped in the pump head (Refer to pic #2) When you go to start the pump up it will cavitate the air with the liquid and its a 50/50 chance it will be able to purge itself of that air. Best thing to do is take the 4 Phillips screws out and rotate the head 180* so the outlet is once again back on the right hand side when looking at it.

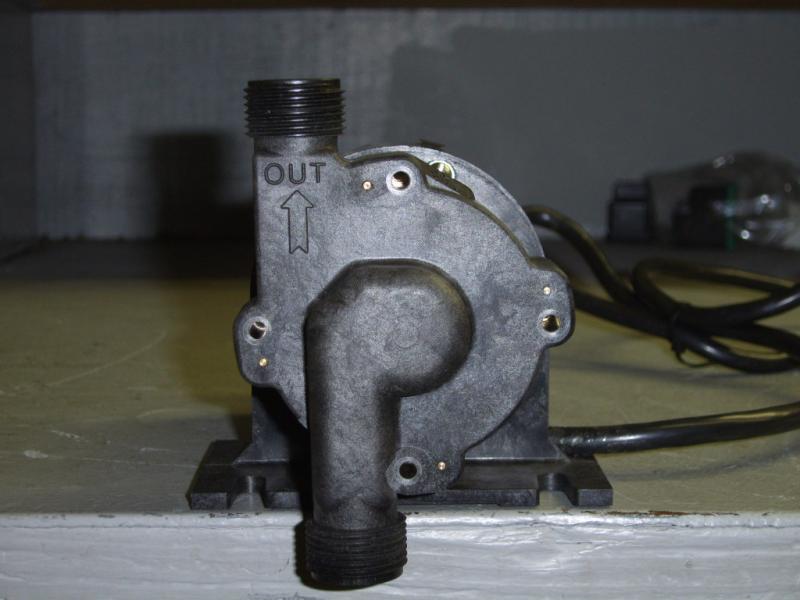

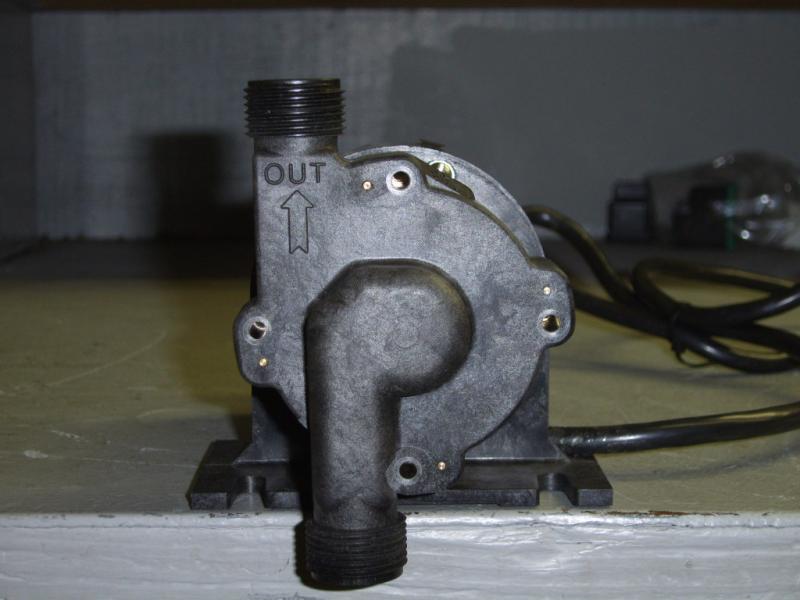

Ideally, if you have the room to rotate the pump head, the best orientation would be with the outlet facing straight up with the inlet on the bottom like in Pic #3

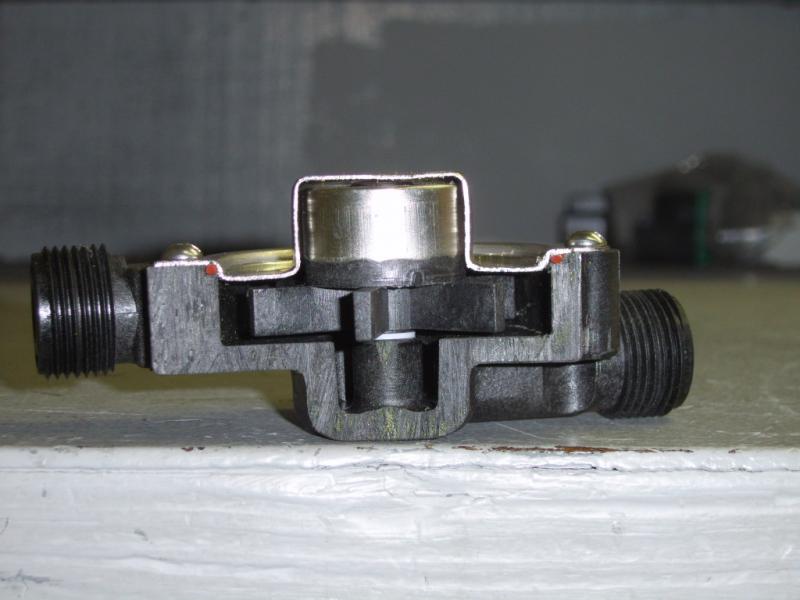

There have been a few people that we have seen with the inlet at the top and outlet on the bottom...that way can also trap air in the pump head (pic #4)

And lastly if space is an issue and the pump gets mounted vertically, then the best way to do that is with the pump head on top of the motor. This is usually met with resistance as most people think if the pump head leaks it will get the motor all wet. While that is true...this orientation is the only way to again get all the air out of the pump head and not have issues with cavitating. Pic #5

The first picture is usually how the pump comes straight out of the box. Pay no attention to the thread size as I just happen to take a custom one off the shelf here in the repair dept for this example. This one has 1" thread fittings on it.

As you can see the outlet is on the right hand side of the picture and the inlet is on the left. The outlet is higher to allow air to escape out of the pump. Some brewers have mounted the pump upside down and that results in an air pocket being trapped in the pump head (Refer to pic #2) When you go to start the pump up it will cavitate the air with the liquid and its a 50/50 chance it will be able to purge itself of that air. Best thing to do is take the 4 Phillips screws out and rotate the head 180* so the outlet is once again back on the right hand side when looking at it.

Ideally, if you have the room to rotate the pump head, the best orientation would be with the outlet facing straight up with the inlet on the bottom like in Pic #3

There have been a few people that we have seen with the inlet at the top and outlet on the bottom...that way can also trap air in the pump head (pic #4)

And lastly if space is an issue and the pump gets mounted vertically, then the best way to do that is with the pump head on top of the motor. This is usually met with resistance as most people think if the pump head leaks it will get the motor all wet. While that is true...this orientation is the only way to again get all the air out of the pump head and not have issues with cavitating. Pic #5