wizardofza

Well-Known Member

Hi all-

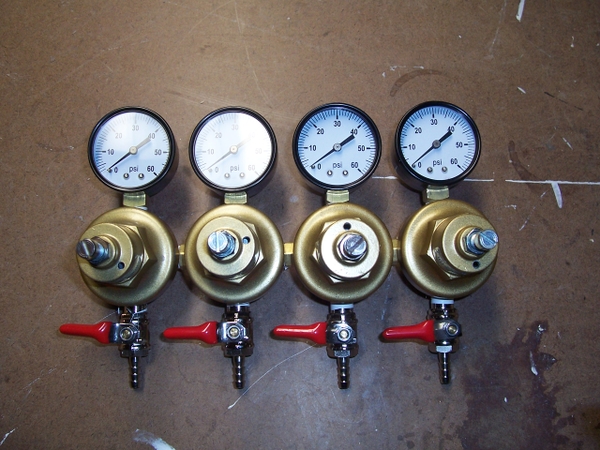

I recently built a kegerator out of a chest freezer. It uses a secondary bank of 4 regulators (of which I purchased from American Science and Surplus - great deal!), and I'm trying to track down a leak somewhere in my system. So far, I've killed about 3-5lb CO2 tanks trying to diagnose this.

I currently have three kegs connected to the secondary and I've checked all hose connections in my kegerator using soapy water in a spray bottle. I checked all the fittings within my secondary bank as well (psi gauges, nipples, etc), and even ensured that the new C02 tank and primary regulator aren't leaking either. So far, it all looks good.

I'm kind of stumped as to where my CO2 is going. So, in desperation I shut off the CO2 tank completely, and I noticed that eventually all 4 psi gauges on my secondary go down to 0 (they're all set at ~ 10psi). If I let the system site with the gas off for a couple hours and come back and turn it on, it sounds like the the system is filling back up with gas.

My question is, if I didn't have a leak, I should be able to shut the gas off, come back in a couple hours, turn it back on, and nothing should happen right? At the very least I shouldn't hear gas rushing through my system should I?

I'm kind of stumped as to where this leak is, and I'm starting to focus more on the secondary bank because of this.

Does anyone have other thoughts or suggestions on what to focus on? I just need some more ideas!

I recently built a kegerator out of a chest freezer. It uses a secondary bank of 4 regulators (of which I purchased from American Science and Surplus - great deal!), and I'm trying to track down a leak somewhere in my system. So far, I've killed about 3-5lb CO2 tanks trying to diagnose this.

I currently have three kegs connected to the secondary and I've checked all hose connections in my kegerator using soapy water in a spray bottle. I checked all the fittings within my secondary bank as well (psi gauges, nipples, etc), and even ensured that the new C02 tank and primary regulator aren't leaking either. So far, it all looks good.

I'm kind of stumped as to where my CO2 is going. So, in desperation I shut off the CO2 tank completely, and I noticed that eventually all 4 psi gauges on my secondary go down to 0 (they're all set at ~ 10psi). If I let the system site with the gas off for a couple hours and come back and turn it on, it sounds like the the system is filling back up with gas.

My question is, if I didn't have a leak, I should be able to shut the gas off, come back in a couple hours, turn it back on, and nothing should happen right? At the very least I shouldn't hear gas rushing through my system should I?

I'm kind of stumped as to where this leak is, and I'm starting to focus more on the secondary bank because of this.

Does anyone have other thoughts or suggestions on what to focus on? I just need some more ideas!