The Pol

Well-Known Member

- Joined

- Feb 12, 2007

- Messages

- 11,390

- Reaction score

- 117

Couple questions for you. I read in one of your posts that you used a dip tube and stopper for your thermowell. How did you seal the end of the dip tube? Also, I have an immersion chiller that I would like to use as my heat exchanger. When I set it in my HLT the top of the coils comes to about the 6 gallon mark. Will this be a problem?

The dip tube is cut to the appropriate length, a rubber seal was inserted into the end and the end was then crimped tight.

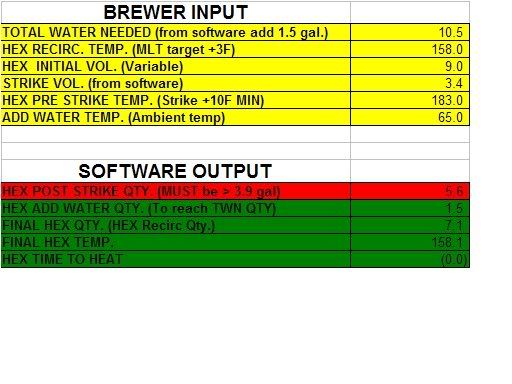

My heat exchanger is 1/2" copper tubing. When you start running this system you will see that you want to have the coil come up to about the 5.5 to 6 gallon mark, MAX... it will be okay. This is based on a couple facts about the HLT. When it is completed you will be able to get 9.5 gallons of water in it MAX, the other volume is filled with the coil and other equipment that you are installing. When I say 9,5 gallons max, I mean 1/4" from the top when the lid is on. Once you pump out your strike water 3-4 gallons, you will have 5.5-6.5 gallons of volume still left in your HLT... so you want your coil to be about that height max.

Also, the use of the 1500W element is based on the fact that it is about 7-8" in length, meaning it will be submerged even if you drop to say 4 gallons in the HLT. DONT LET THE ELEMENT RUN DRY!