You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

120V Small Batch Brewing Setup

- Thread starter DeeDub76

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

i see them just fine.

samc

Well-Known Member

I'm going to nominate that control box as the largest one ever for a system to do 3 gallons. That thing is shiny and huge. I want!

ScubaSteve

Well-Known Member

- Joined

- May 21, 2007

- Messages

- 3,673

- Reaction score

- 91

Very nice! I like that clean style....

And yeah, that's a HUGE box! Keep us posted on your build

And yeah, that's a HUGE box! Keep us posted on your build

DeeDub76

Well-Known Member

A few parts came in allowing me to build the tri-clamp heating element.

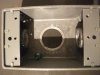

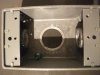

Some milling was required in the box so the heating element would sit properly.

Tri-clamp allows quick removal for cleaning or element replacement.

A few sanitary ferrules that will be welded to the vessel hopefully within the next week.

Some milling was required in the box so the heating element would sit properly.

Tri-clamp allows quick removal for cleaning or element replacement.

A few sanitary ferrules that will be welded to the vessel hopefully within the next week.

DeeDub76

Well-Known Member

Very nice! I like that clean style....

And yeah, that's a HUGE box! Keep us posted on your build

__________________

I agree!! It's a little big at 16x16x6, but at only $52 shipped from ebay I couldn't pass it up. Plus most of the switch holes were already punched.

rrittenhouse

Well-Known Member

This is a project I want to do someday when the wife will give me a brewing budget from my paycheck. haha.Subscribed.

- Joined

- Nov 6, 2007

- Messages

- 62,016

- Reaction score

- 6,922

Can't tell. Is that a plastic electrical box that you have your ground screw in???

Can't tell. Is that a plastic electrical box that you have your ground screw in???

That's a standard cast aluminum outdoor single gang box.

Looks very nice.

- Joined

- Nov 6, 2007

- Messages

- 62,016

- Reaction score

- 6,922

Good deal, I was concerned.

Beautiful looking build. I'm doing a small batch 120 system took, but going with jkarps build. Much cheaper. Won't look as purty as yours though.

Beautiful looking build. I'm doing a small batch 120 system took, but going with jkarps build. Much cheaper. Won't look as purty as yours though.

How many watts is your element? I was thinking of building a smaller 3-4 gal setup myself. Mainly because I have like 15 5gal carboys that are useless for true 5gal batches.

- Joined

- Nov 6, 2007

- Messages

- 62,016

- Reaction score

- 6,922

If you want to stick with a standard 120V 20A kitchen outlet, you're maxing out at 2000W. Good enough for these 3.5G bathes.

DeeDub76

Well-Known Member

This build is no longer going to be 120V. I am stepping up to 220V for the ease of wiring. With 220V I can simply run wire for one 220V outlet vs. running two seperate 20A circuits. 220V will also effeciently handle all my electrical needs for this setup. The lowest wattage for a 220V heating element I can find is 3800 watts. More than enough for this small setup.

This build is no longer going to be 120V. I am stepping up to 220V for the ease of wiring. With 220V I can simply run wire for one 220V outlet vs. running two seperate 20A circuits. 220V will also effeciently handle all my electrical needs for this setup. The lowest wattage for a 220V heating element I can find is 3800 watts. More than enough for this small setup.

Keep in mind that you can take a 240V element and run it on 120V. You'll get 1/4th the power out of the element and draw half the amps that it would draw at 240V.

So, 5500W/240V element can be used as a 1375W/120V element, drawing 11.5A.

GatorBrewer

New Member

A few parts came in allowing me to build the tri-clamp heating element.

View attachment 19398

View attachment 19399

Some milling was required in the box so the heating element would sit properly.

View attachment 19400

View attachment 19401

Tri-clamp allows quick removal for cleaning or element replacement.

View attachment 19402

A few sanitary ferrules that will be welded to the vessel hopefully within the next week.

I love it! What parts did you order for that heating element setup? From Brewers Hardware?

Boerderij_Kabouter

Well-Known Member

FYI:

a 120VAC 2000W element easily produces a good boil in 5 gallons of wort. IMO, for 3.5g batches 240VAC is overkill and pretty seriously complicates the wiring. But, its your build.

a 120VAC 2000W element easily produces a good boil in 5 gallons of wort. IMO, for 3.5g batches 240VAC is overkill and pretty seriously complicates the wiring. But, its your build.

FYI:

a 120VAC 2000W element easily produces a good boil in 5 gallons of wort. IMO, for 3.5g batches 240VAC is overkill and pretty seriously complicates the wiring. But, its your build.

It could be done in a way that actually simplifies things.

Instead of plugging into two separate 120V circuits, he could plug into one 240V circuit, but split that into two separate 120V domains inside his panel.

So, everything could still be 120V, but it just gets fed with a single 240V source.

Boerderij_Kabouter

Well-Known Member

My question is why do you need two 120VAC circuits??? IRL, a 2000W element pump and a bunch of other crap still doesn't overload even a 15amp circuit while boiling 5g.

I know the science doesn't quite work, but I can tell you reality and electronics meet in a gray area almost everytime.

My comment was to say, just use one 120VAC outlet and be done with it. Simple and clean.

I know the science doesn't quite work, but I can tell you reality and electronics meet in a gray area almost everytime.

My comment was to say, just use one 120VAC outlet and be done with it. Simple and clean.

My question is why do you need two 120VAC circuits??? IRL, a 2000W element pump and a bunch of other crap still doesn't overload even a 15amp circuit while boiling 5g.

I know the science doesn't quite work, but I can tell you reality and electronics meet in a gray area almost everytime.

My comment was to say, just use one 120VAC outlet and be done with it. Simple and clean.

A 2000W/120V element will draw 16.7A all by itself. If it doesn't trip a 15A breaker, especially with a pump and other stuff running, then I would be concerned.

- Joined

- Nov 6, 2007

- Messages

- 62,016

- Reaction score

- 6,922

But a 20A would and that's not hard to come by. I wonder the same thing. for a 3.5G setup, why would you need two outlets? If you only have a 15A outlet in the wall, replace it with a 20A.

Yes, I'd think that 120V/20A would be fine for this.

But... I'm also the kind of guy that knows I won't stop upgrading. If I am going to pay or do the work to install a new circuit, wiring, and outlets for brewing, I'm going to put 240V/50A in and then just use what I need with whatever system I have at the time.

In fact, that's exactly what I did in my garage. I only *need* about 25A for my brewing system, but I have 50A available if I ever want it.

But... I'm also the kind of guy that knows I won't stop upgrading. If I am going to pay or do the work to install a new circuit, wiring, and outlets for brewing, I'm going to put 240V/50A in and then just use what I need with whatever system I have at the time.

In fact, that's exactly what I did in my garage. I only *need* about 25A for my brewing system, but I have 50A available if I ever want it.

ScubaSteve

Well-Known Member

- Joined

- May 21, 2007

- Messages

- 3,673

- Reaction score

- 91

You must've gotten your other ferrules from BrewMagic? 1/2" and 3/4" triclover stuff is hard to find!

rrittenhouse

Well-Known Member

I can understand wanting more headroom for further expansion. However, I would like to see someone else do this with 120V/20A as I am currently a renter and I think it wouldn't be smart to pay someone to run 220v for a brew system.

DeeDub76

Well-Known Member

But a 20A would and that's not hard to come by. I wonder the same thing. for a 3.5G setup, why would you need two outlets?

Still being somewhat new to the brewing world. I was under the thinking that at some point during the brewing process it was necessary to run both heating elements at the same time, therfore requiring two 20A outlets. Knowing now that is not necessary I would like to continue with my original plan of 120V setup. Using a 3 position switch to select between heating elements would prevent both elements ever being turned on at the same time.

I work in the bio/pharm industry. (wink wink)You must've gotten your other ferrules from BrewMagic? 1/2" and 3/4" triclover stuff is hard to find!

- Joined

- Nov 6, 2007

- Messages

- 62,016

- Reaction score

- 6,922

I can understand wanting more headroom for further expansion. However, I would like to see someone else do this with 120V/20A as I am currently a renter and I think it wouldn't be smart to pay someone to run 220v for a brew system.

Still being somewhat new to the brewing world. I was under the thinking that at some point during the brewing process it was necessary to run both heating elements, therfore requiring two 20A outlets. Knowing now that is not necessary I would like to continue with my original plan of 120V setup. Using a 3 position switch to select between heating elements would prevent both elements ever being turned on at the same time.

I work in the bio/pharm industry. (wink wink)

To both of these. Take a look at jKarps Counter top Brutus 20. It's what I'm in the process of making too. 2 vessel 120V 20A setup with one heating element and one pump. 3.5G batches.

If all goes well, I'll be also (in the future) making a 10G version for the garage using a 240V/50A outlet.

BeantownD

Well-Known Member

It could be done in a way that actually simplifies things.

Instead of plugging into two separate 120V circuits, he could plug into one 240V circuit, but split that into two separate 120V domains inside his panel.

So, everything could still be 120V, but it just gets fed with a single 240V source.

I did the same thing with my rig. I have 2 2000W heatsticks that are fed from a 240V On a 30A breaker. I have room for both heatsticks a pump and an agitator that I built for my HLT. Not as nice as Kal's (who's is?), but it's effective.

jkarp

Well-Known Member

This puppy's gonna be a thing of beauty. Subscribed.

DeeDub76

Well-Known Member

DeeDub76

Well-Known Member

Awesome weldless sight glass from Bobby.

Tri-clamp heating elements wired and in place.

Wires dropped into control panel. I am accumulating a lot of electrical parts, but still waiting on a few items to get the control panel underway.

An aerial view of the kettles. MLT on the right and BK on the left. Both will have false bottoms.

Tri-clamp heating elements wired and in place.

Wires dropped into control panel. I am accumulating a lot of electrical parts, but still waiting on a few items to get the control panel underway.

An aerial view of the kettles. MLT on the right and BK on the left. Both will have false bottoms.

- Joined

- Nov 6, 2007

- Messages

- 62,016

- Reaction score

- 6,922

Looks really clean so far. nice work.

ScubaSteve

Well-Known Member

- Joined

- May 21, 2007

- Messages

- 3,673

- Reaction score

- 91

This build is awesome....it makes me want to start mine all over again! I like that clean look...you're going to have a really nice rig!

rrittenhouse

Well-Known Member

*Fap* *Fap* *Fap* - Brew Pr0n!

It looks VERY nice. I really like how this build is taking shape. Keep us up to date! (and jealous!)

It looks VERY nice. I really like how this build is taking shape. Keep us up to date! (and jealous!)

Similar threads

- Replies

- 23

- Views

- 1K

- Replies

- 24

- Views

- 1K